Polystyrene mercury ion fluorescence recognition materials and preparation method thereof

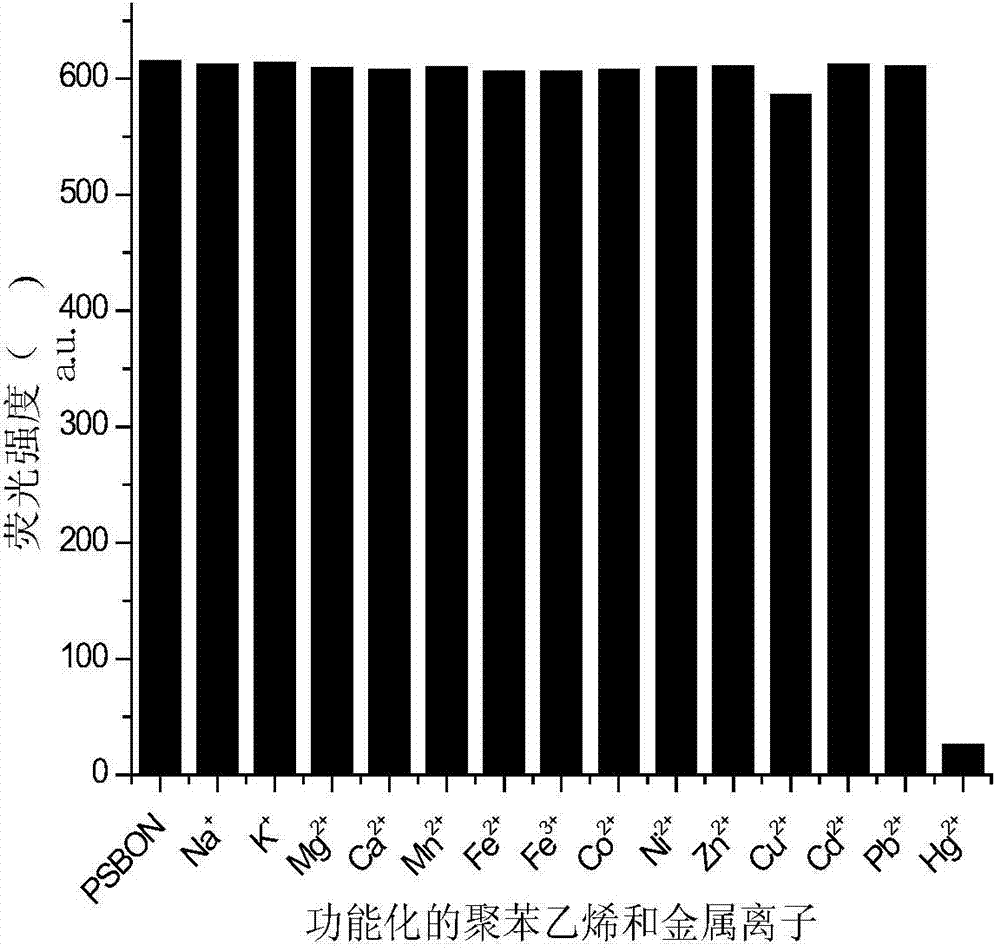

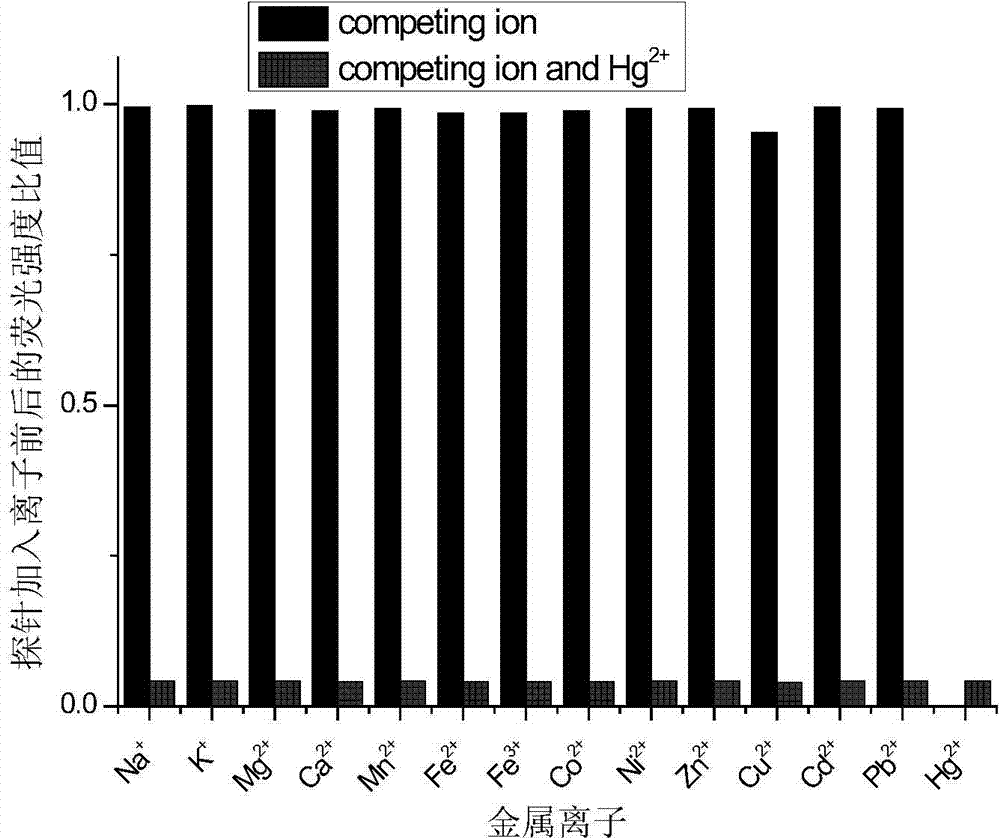

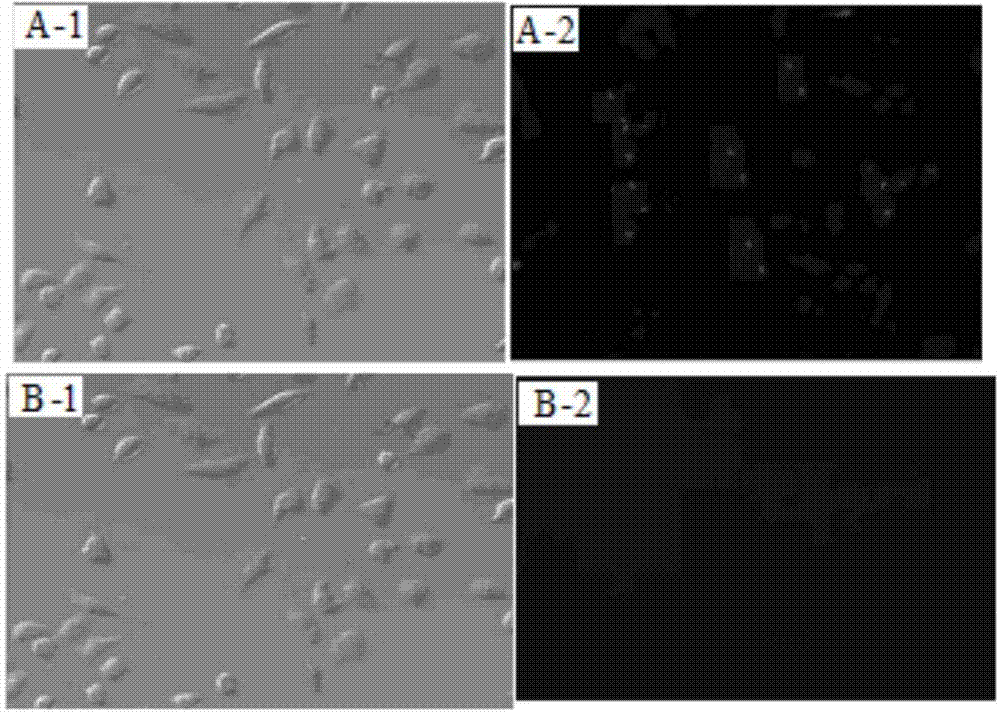

A polystyrene and fluorescence recognition technology, applied in the fields of luminescent materials, fluorescence/phosphorescence, material excitation analysis, etc., can solve the problems of fluorescent recognition materials that can only be detected but cannot be separated, fluorescence quenching signal amplification, and detection materials that cannot be reused.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The invention provides a functionalized polystyrene Hg 2+ The preparation method of the fluorescent recognition material is specifically implemented according to the following steps:

[0038] Step 1, preparation of amino-2-(4'-hydroxyl-3'-(di-(2"-ethylthioethyl)amino)phenyl-benzo[d]oxazole (BOS, VII), the specific The synthetic route is shown in the following formula 1 - formula 4

[0039]

[0040] Specifically follow the steps below:

[0041] Step 1.1, the preparation of two-(2-ethylthioethyl)amine (Ⅲ)

[0042] Add diethanolamine (Compound I) into chloroform, slowly add thionyl chloride at -5°C-5°C, wherein the molar volume ratio (mol / ml) of diethanolamine to chloroform is 1:500-1:700 ; The molar ratio of diethanolamine to thionyl chloride is 1:3-1:5; After reacting at room temperature for 1.5h-2.5h, heat up to reflux for 2.5h-3.5h, cool, add ethanol to the reaction solution to remove excess Thionyl chloride. The solvent was distilled off under reduced pressure...

Embodiment 1

[0069] A functionalized polystyrene Hg 2+ The preparation method of the fluorescent recognition material is specifically implemented according to the following steps:

[0070] Step 1, preparation of 5-amino-2-(4'-hydroxyl-3'-(two-(2"-ethylthioethyl) amino)phenyl-5-aminobenzo[d]oxazole (BOS, VII);

[0071] A. Preparation of Di-(2-Ethylthioethyl)amine (Ⅲ)

[0072] Add 5.25g (0.05mol) of di-ethanolamine compound 1 into 30mL of chloroform, slowly add 23.8g of thionyl chloride at 0°C, react at room temperature for 2.0h, heat up to reflux for 3h, cool, and add Ethanol removes excess thionyl chloride. The solvent was distilled off under reduced pressure, and then a small amount of chloroform and diethyl ether were added to produce a white solid. After suction filtration, the solid was washed several times with diethyl ether and dried in vacuo to obtain 8.4 g of a white solid, i.e., di-(2-chloroethyl)amine salt acid salt, the yield was 95.2%.

[0073] Under the protection of nitr...

Embodiment 2

[0090] Step 1, preparation of amino-2-(4'-hydroxyl-3'-(two-(2"-ethylthioethyl) amino)phenyl-benzo[d]oxazole (BOS, VII), specifically according to The following steps are implemented:

[0091] Step 1.1, the preparation of di-(2-ethylthioethyl)amine (Ⅲ), specifically: adding diethanolamine (compound I) into chloroform, slowly adding thionyl chloride at -5°C-5°C , wherein, the molar volume ratio (mol / ml) of diethanolamine and chloroform is 1:500; The molar ratio of diethanolamine and thionyl chloride is 1:3; After reacting at room temperature for 2.5h, heat up to reflux reaction for 3.5h, cool , Ethanol was added to the reaction solution to remove excess thionyl chloride. Remove the solvent by distillation under reduced pressure, then add chloroform and diethyl ether, the molar volume ratio (mol / mL / mL) of diethanolamine, chloroform and diethyl ether is 1:40:120, a white solid is produced, suction filtered, and the solid is washed several times with diethyl ether , and dried in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com