Method for preparing concentrated fish oil fatty acid glyceride

A technology of fatty acid glyceride and fatty acid ethyl ester, which is applied in the production and fermentation of bulk chemicals, can solve the problems of high cost, long synthesis route, low DHA and EPA purity, etc., and achieves the effect of reducing cost and simplifying process steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

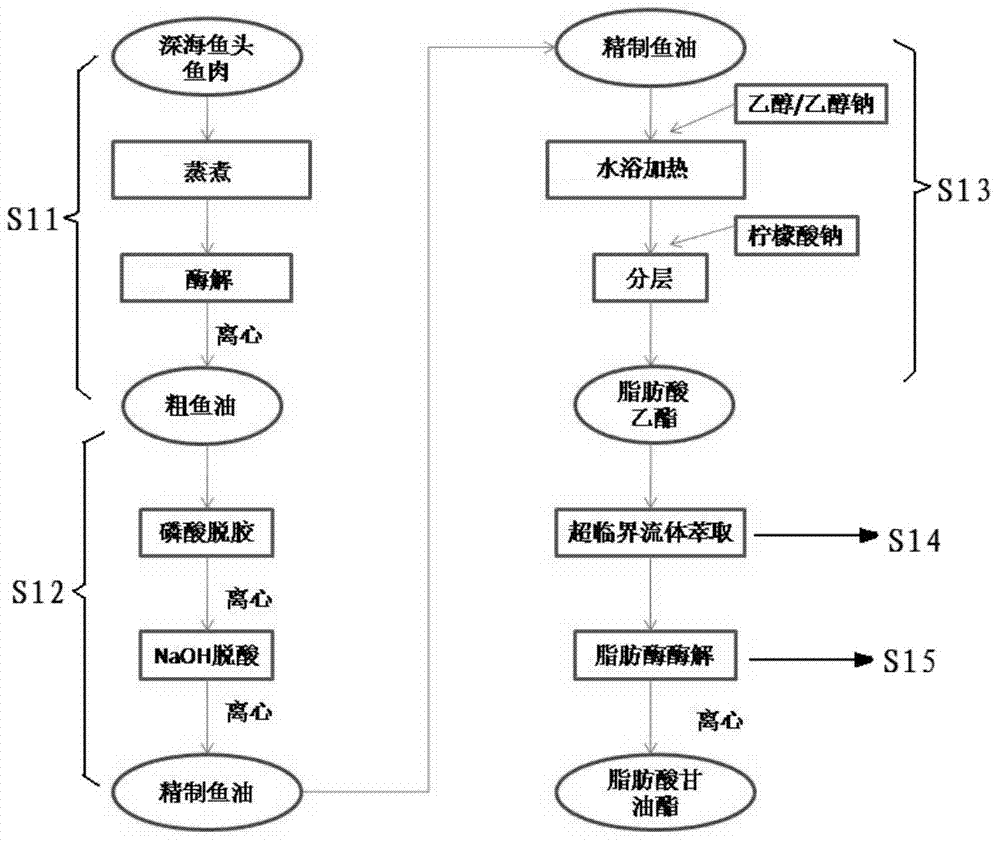

[0041] A method for preparing concentrated fish oil fatty acid glycerides, the process steps are as follows figure 1 As shown, including the following steps:

[0042] S11. Use enzymatic hydrolysis technology to prepare deep-sea fish crude fish oil: deep-sea fish is crushed by a bone crusher to form a minced meat, weigh 600g of meat slurry, add water to seal at the ratio of meat:water=0.5:1 (m:m), and place it in a dark room , Under the condition of nitrogen gas, cook at 75℃ for 1h. Use NaOH to adjust the pH to 8.0. Add 2% trypsin (trypsin: food grade, Zhengzhou Hongcheng Chemical Products Co., Ltd.), and enzymolyze it in a dark room at 20°C for 17 hours. After centrifugation at 3000r / min for 20 minutes, take the upper enzymatic hydrolysate, which is crude fish oil;

[0043] S12. Preparation of refined fish oil: add 0.5% phosphoric acid (phosphoric acid: crude fish oil) by volume to the crude fish oil prepared in step S11 for degumming, the concentration of phosphoric acid is 70%...

Embodiment 2

[0048] A method for preparing concentrated fish oil fatty acid glycerides includes the following steps:

[0049] S21. Preparation of crude deep-sea fish oil using enzymatic hydrolysis technology: refer to step 11 of Example 1, wherein the cooking temperature is 85°C, the enzymatic hydrolysis temperature is 25°C, and the centrifugal speed is 4000r / min;

[0050] S22. Preparation of refined fish oil: refer to step 12 of Example 1; wherein the volume ratio of phosphoric acid: crude fish oil is 1.5%, the concentration of phosphoric acid is 75%; the volume ratio of KOH: crude fish oil is 3%, and the concentration of KOH is 30% , The centrifugal speed is 4000r / min;

[0051] S23. Esterification of refined fish oil to prepare fatty acid ethyl esters: refer to step 13 of Example 1; wherein the mass ratio of potassium ethoxide: refined fish oil is 1.0%, the mass ratio of ethanol: refined fish oil is 2.0, and the heat treatment is 60°C water bath heating In 3 hours, acetic acid was added and th...

Embodiment 3

[0055] A method for preparing concentrated fish oil fatty acid glycerides includes the following steps:

[0056] S31. Preparation of crude deep-sea fish oil using enzymatic hydrolysis technology: refer to step 11 of Example 1, wherein the cooking temperature is 90°C, the enzymatic hydrolysis temperature is 35°C, and the centrifugal speed is 5000r / min;

[0057] S32. Preparation of refined fish oil: refer to step 12 of Example 1; wherein the volume ratio of phosphoric acid: crude fish oil is 3%, the concentration of phosphoric acid is 85%; the volume ratio of NaOH: crude fish oil is 6%, and the concentration of NaOH is 50% , The centrifugal speed is 5000r / min;

[0058] S33. Esterification of refined fish oil to prepare fatty acid ethyl esters: refer to step 13 of Example 1; wherein the mass ratio of potassium ethoxide: refined fish oil is 1.5%, the mass ratio of ethanol: refined fish oil is 4.0, and the heat treatment is 80°C water bath heating In 5 hours, citric acid is added and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com