Preparation method of aluminum-base graphene composite material

A composite material and graphene technology, which is applied in the field of preparation of aluminum-based graphene composite materials, can solve the problems of increasing interface reaction, hindering the interface reaction of composite materials, complicated process, etc., to simplify the process, reduce harmful interface reactions, The effect of performance guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

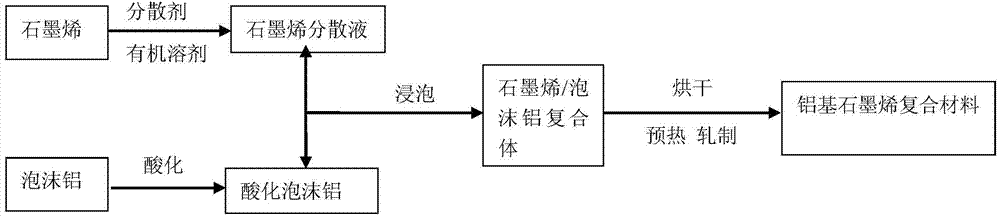

Method used

Image

Examples

Embodiment 1

[0026] A method for preparing an aluminum-based graphene composite material, specifically comprising the following steps

[0027] 1) Mix 0.1g of graphene (the diameter of graphene is 10um, provided by Chengdu Organic) and 0.4g of dispersant cellulose, then add it to 100ml of ethanol, and use ultrasonic dispersion for 1 hour to form graphene dispersion Liquid (the content of graphene in graphene dispersion liquid is 1mg / ml).

[0028] 2) Put 4g of aluminum foam with interconnected pores in 5wt% dilute hydrochloric acid to clean and remove the oxide layer, and then dry it.

[0029] 3) Soak the aluminum foam with connected pores processed in step 2) in the graphene dispersion, soak for 2 hours, take it out, and dry it in a vacuum oven to obtain a graphene / aluminum foam composite. The vacuum degree in the vacuum oven is 0.05 mbar, drying temperature is 100 degrees.

[0030] 4) Place the dried graphene / foamed aluminum composite in an electric furnace to preheat to 300 degrees, and...

Embodiment 2

[0031] Embodiment 2 The difference between this embodiment and Example 1 is that the graphene added in step 1) is 0.01g (the content of graphene in the graphene dispersion is 0.1mg / ml), and the resulting aluminum-based graphene composite The thermal conductivity of the material is 180W / m.K, and the thermal expansion coefficient is 15×10 -6 m / K.

Embodiment 3

[0032] Embodiment 3 The difference between this embodiment and Example 1 is that the graphene added in step 1) is 0.2g (the content of graphene in the graphene dispersion is 2mg / ml), the heat of the gained aluminum-based graphene composite material The conductivity reaches 375W / m.K, and the thermal expansion coefficient is only 6×10 -6 m / K.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com