Method for depositing high-K gate dielectric on atomic layer on surface of graphene

A graphene surface and atomic layer deposition technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problem of inability to ensure good contact between the metal and the bottom graphene, and the inability to deposit high-k gate dielectrics and graphene lattices Damage and other problems, to achieve the effect of tight combination, good uniformity and continuity, and small lattice damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in combination with specific embodiments and with reference to the accompanying drawings. In this example, only Al 2 O 3 gate dielectric layer, but the dielectric layer is not doped. It should be understood that these descriptions are exemplary only, and are not intended to limit the scope of the present invention. Also, in the following description, descriptions of well-known structures and techniques are omitted to avoid unnecessarily obscuring the concept of the present invention.

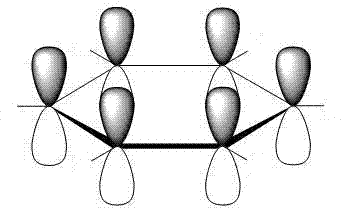

[0029] figure 1 It is a schematic diagram of the S orbitals between the six carbon atoms of graphene and the six P orbitals perpendicular to the two-dimensional plane.

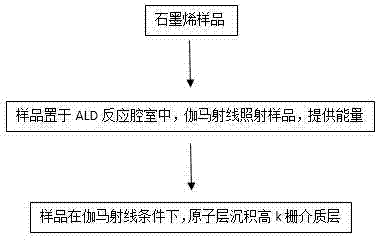

[0030] The rays used in this example are gamma rays but are not limited to gamma rays, other rays can also be used, and the method of the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com