Method for making fungus chaff feed raw material by adopting two-stage fermentation method

A technology of feed raw materials and fermented raw materials, applied in animal feed, animal feed, applications, etc., can solve problems such as rough texture, poor palatability, easy to spoil and deteriorate, and achieve the effects of easy digestion and absorption, inhibition of growth, and promotion of farmers' income

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

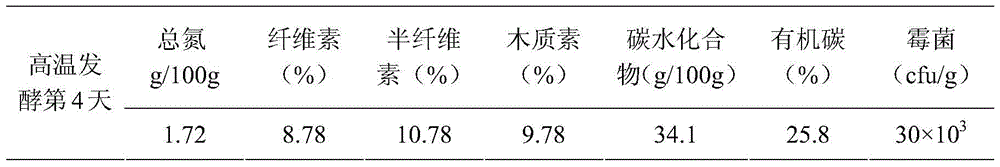

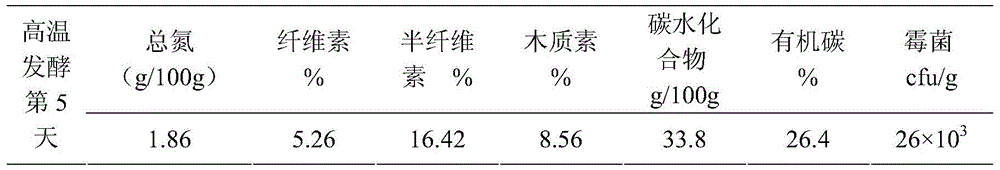

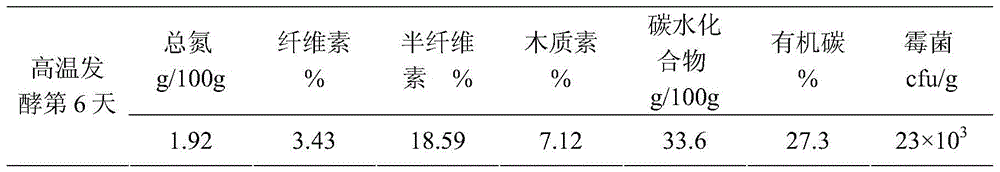

Examples

example 1

[0027] 1) Collection of mushroom chaff and analysis of nutritional components: collect fresh Pleurotus eryngii or Flammulina velutipes mushroom chaff from edible fungus production enterprises, measure moisture, dry matter, C, and N content, and transfer them to high-temperature fermentation tanks in time; The fermentation tank is 40m long, 1.5m wide and 1m deep.

[0028] 2) In the high-temperature fermentation tank, calculate the moisture, nitrogen source, and calcium hydrogen phosphate that need to be added according to the analysis data of the raw material moisture, dry matter, C, and N in the fermentation tank and the total mass of the bacteria chaff in the fermentation tank; The nitrogen source and tap water are fully mixed, the C / N is adjusted to 25, and the moisture is adjusted to 55%;

[0029] 3) Spray the fermented pyrolysis fermentation compound bacterial liquid on the bacterial chaff raw material in step 2); the spraying amount is 1% of the weight of the bacterial ch...

example 2

[0040] Example 2, same as Example 1, the difference is,

[0041] 1) The high-temperature fermentation tank is 60m long, 1.7m wide and 1.2m deep.

[0042] 2) Adjust C / N to 30, moisture to 60%;

[0043] 3) Spraying the fermented pyrolysis fermentation composite bacterial liquid; the spraying amount is 2% of the weight of the bacterial chaff raw material in step 2);

[0044] The content of the number of cells of each strain in the pyrolysis fermentation compound bacterial liquid is: 3% of Brevibacillus thermoruber (DSM 7064), 27% of Clostridium thermocellum (ATCC27405), 27% of Desulfotomaculum nigrificans (DSM 574) 20%, Geobacillus thermoglucosidasius (DSM 21625) 25%, Symbiobacterium thermophilum (DSM 24528) 25%;

[0045] 4) Pile and level off the fungus chaff raw material sprayed with pyrolysis and fermentation compound bacterial solution in step 3, the height of the pile is 80cm, carry out static fermentation for 48 hours, the temperature in the middle of the pile rises to a ...

example 3

[0053] Example 3, the same as Example 1, the difference is,

[0054] 1) The high temperature fermentation tank is 50m long, 1.6m wide and 1.1m deep.

[0055] 2) Adjust C / N to 28, moisture to 65%;

[0056] 3) Spraying the fermented pyrolysis fermentation composite bacterial liquid; the spraying amount is 2% of the weight of the bacterial chaff raw material in step 2);

[0057] The content of the number of cells of each strain in the pyrolysis and fermentation compound bacterial liquid is as follows: 5% of Brevibacillus thermoruber (DSM 7064), 25% of Clostridium thermocellum (ATCC27405), 25% of Desulfotomaculum nigrificans (DSM 574) 20%, Geobacillus thermoglucosidasius (DSM 21625) 22%, Symbiobacterium thermophilum (DSM 24528) 28%;

[0058] 4) Pile up the raw material of the chaff that has been sprayed with the pyrolysis and fermentation compound bacterial solution in step 3, and pile up to a height of 50 cm, and carry out static fermentation for 36 hours. Turn the compost onc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com