Heat-absorbing coating and preparation method thereof

An endothermic coating, a technology of parts by weight, applied in the field of coatings, can solve problems such as influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1 A heat-absorbing coating and its preparation method

[0050] The heat-absorbing paint is made of equal parts of powdery component A1, powdery component B1 and component C1, wherein component A1 includes chromium oxide green, cobalt oxide, manganese oxide and iron red powder; component B1 includes aluminum oxide , zinc oxide, bauxite powder, silicon carbide and bentonite; component C1 includes potassium silicate and silicon phosphate. The various materials and silicon phosphate in the above-mentioned component A1 and component B1 are all commercially available powdery materials.

[0051] The preparation method of the endothermic coating of the present embodiment is carried out according to the following steps:

[0052] (11) Preprocessing

[0053] Weigh 6kg of chromium oxide green, 4.5kg of cobalt oxide, 4.5kg of manganese oxide and 11kg of iron red powder to form a component A1, stir and mix and sinter in a muffle furnace to obtain a1;

[0054] Among them,...

Embodiment 2-6

[0071] Example 2-6 Heat-absorbing paint and preparation method thereof

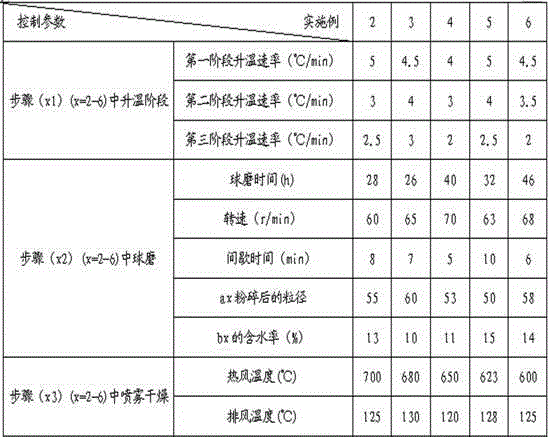

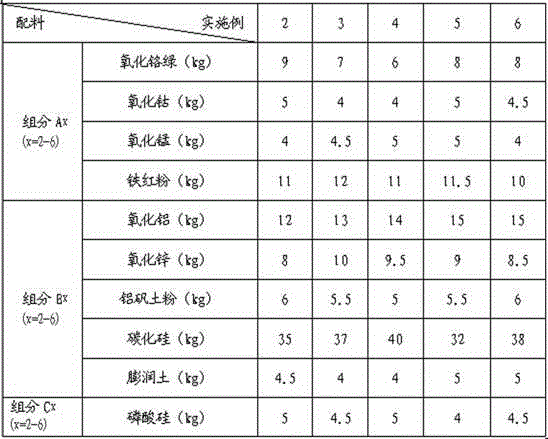

[0072] The present embodiment is respectively a kind of heat-absorbing paint and preparation method thereof, and the preparation steps are similar to embodiment 1, and the weight of the potassium silicate used is 95kg, and the used sieve hole when cx (x=2-6) sieves is uniform. It is 325 mesh, the holding time in the heating stage is the same, the method in the cooling stage is also the same, and the ball-to-material ratio is 3:1 during ball milling. The only difference is that the ingredients and other control parameters in the preparation process are different. See Table 1 and Table 2.

[0073] Table 1 Ingredients of paint (except potassium silicate) table

[0074]

[0075] Table 2 Technical parameter table (part) in the coating preparation process

[0076]

[0077] The paint prepared in Examples 2-6 was brushed on the radiant heating surface of the boiler (the outer wall of the water-cooled ...

Embodiment 7

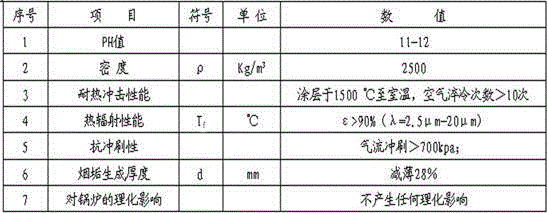

[0080] Example 7 Main technical indicators of energy-saving and heat-absorbing coatings

[0081] In this embodiment, the heat-absorbing coatings prepared in Examples 1-6 are detected, wherein, the detection of pH value and density is to directly use corresponding instruments to detect the finished coatings, and the rest of the technical indicators are all using Example 1 -The paint brush made in 6 is tested on the radiant heating surface of the boiler (the outer wall of the water-cooled wall tube) (the specific painting process is the same as that in Examples 1-6), and the specific technical indicators are shown in the table below.

[0082] Table 3 technical index table

[0083]

[0084] It can be seen from the above Table 3 that the heat-absorbing coating prepared by the present invention has good thermal shock resistance, thermal radiation performance, and erosion resistance, and it can reduce the thickness of soot formation without affecting the physical and chemical e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com