Method for preparing tin dioxide directly by using tin-electrolyzed anode mud

A technology of tin dioxide and anode slime, applied in tin oxide and other directions, can solve the problems of products easily containing impurities, high equipment requirements, poor working conditions, etc., to achieve environmental protection, wide market applications, and strong market competitiveness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

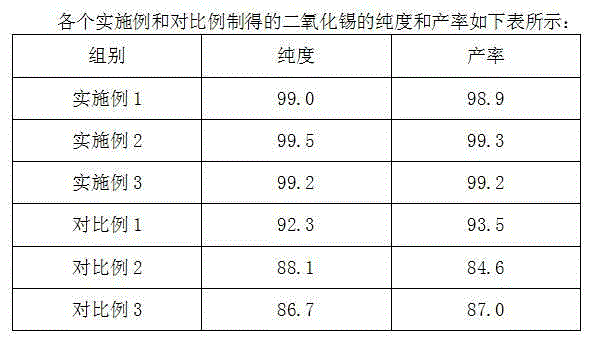

Examples

Embodiment 1

[0017] A method for directly producing tin dioxide from tin electrolytic anode slime, the specific steps are: drying tin electrolytic anode slime at 60°C, crushing, passing through a 40-mesh sieve, heating at 700°C for 30 minutes, and then adding The mixed solution of hydrochloric acid, nitric acid, hydrogen peroxide, sodium chlorate, and potassium chlorate, which is 0.5 times the mass of tin electrolytic anode slime, is reacted at 60°C for 30 minutes, then centrifugally filtered, and the filter residue is added with sodium sulfite and sodium thiosulfate with a solid-to-liquid ratio of 1:0.5 , ammonium thiosulfate mixed solution was stirred for 2 hours, then precipitated, washed with water, filtered, and the filter residue was dried at 60°C, crushed, and packaged to obtain an industrial-grade tin dioxide product.

[0018] The concentration of hydrochloric acid is 1mol / L, the concentration of nitric acid is 1mol / L, the concentration of hydrogen peroxide is 1mol / L, the concentrat...

Embodiment 2

[0021] A method for directly producing tin dioxide from tin electrolytic anode slime, the specific steps are: drying tin electrolytic anode slime at 100°C, crushing, passing through a 40-mesh sieve, heating at 800°C for 60 minutes, and then adding The mixed solution of hydrochloric acid, nitric acid, hydrogen peroxide, sodium chlorate, and potassium chlorate, which is twice the mass of tin electrolytic anode slime, was reacted at 80°C for 50 minutes, then centrifugally filtered, and the filter residue was added with sodium sulfite and sodium thiosulfate with a solid-to-liquid ratio of 1:1. The mixed solution of ammonium thiosulfate and ammonium thiosulfate was stirred for 2.5 hours, then precipitated, washed with water, filtered, and the filter residue was dried at 200°C, crushed, and packaged to obtain an industrial-grade tin dioxide product.

[0022] Wherein the concentration of hydrochloric acid is 3mol / L, the concentration of nitric acid is 5mol / L, the concentration of hydr...

Embodiment 3

[0025] A method for directly producing tin dioxide from tin electrolytic anode slime, the specific steps are: drying tin electrolytic anode slime at 200°C, crushing, passing through a 40-mesh sieve, heating at 1000°C for 100 minutes, and then adding A mixed solution of hydrochloric acid, nitric acid, hydrogen peroxide, sodium chlorate, and potassium chlorate that is 3.5 times the mass of tin electrolytic anode slime was reacted at 90°C for 60 minutes, then centrifugally filtered, and the filter residue was added with sodium sulfite and sodium thiosulfate with a solid-to-liquid ratio of 1:1.5 The mixed solution of ammonium thiosulfate and ammonium thiosulfate was stirred for 3 hours, then precipitated, washed with water, filtered, and the filter residue was dried at 300°C, crushed, and packaged to obtain an industrial-grade tin dioxide product.

[0026] Wherein the concentration of hydrochloric acid is 6mol / L, the concentration of nitric acid is 10mol / L, the concentration of hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com