CoSx nanomaterial used as super capacitor electrode and preparation method of CoSx nanomaterial

A technology of supercapacitors and nanomaterials, applied in the direction of hybrid capacitor electrodes, nanotechnology for materials and surface science, chemical instruments and methods, etc., can solve the problems of being unable to provide high energy density and high power density at the same time, and achieve distribution Dense, easy to operate, and increase the effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

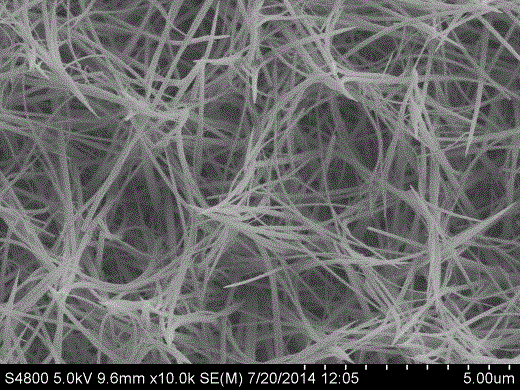

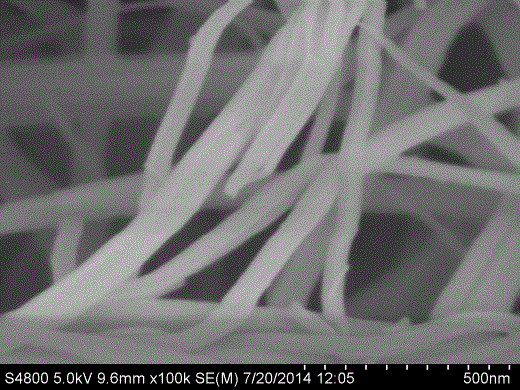

[0039] 1) Precursor formation: use an analytical balance to weigh Co(NO 3 ) 2 ·6H 2 O 、CO(NH 2 ) 2 , NH 4 Cl was dissolved in deionized water, stirred on a magnetic stirrer at room temperature to form a solution with uniform concentration; then transferred to a polytetrafluoroethylene-lined reactor, and the previously prepared nickel foam substrate was immersed in the reactor In the solution, and then placed in a 120 ° C oven for 6 h, naturally cooled to room temperature. After the end, the substrate was taken out and washed and dried to obtain the precursor Co(CO 3 ) 0.35 Cl 0.20 (OH) 1.10 The substrate of the nanowires.

[0040] 2) Vulcanization treatment: Weigh Na 2 S is dissolved in deionized water and configured as 0.65mol / L Na 2 S aqueous solution and transferred to the hydrothermal reactor, with the precursor Co(CO) obtained in step 1 3 ) 0.35 Cl 0.20 (OH) 1.10 The substrate of the nanowires continues to serve as the substrate, immersed in the Na in the r...

Embodiment 2

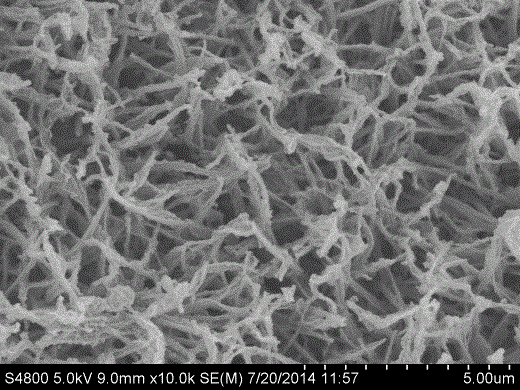

[0042] 1) Precursor formation: use an analytical balance to weigh Co(NO 3 ) 2 ·6H 2 O 、CO(NH 2 ) 2 , NH 4 Cl was dissolved in deionized water, stirred on a magnetic stirrer at room temperature to form a solution with uniform concentration; then transferred to a polytetrafluoroethylene-lined reactor, and the previously prepared nickel foam substrate was immersed in the reactor In the solution, and then placed in an oven at 110 ° C for 8 h, naturally cooled to room temperature. After the end, the substrate was taken out and washed and dried to obtain the precursor Co(CO 3 ) 0.35 Cl 0.20 (OH) 1.10 The substrate of the nanowires.

[0043] 2) Vulcanization treatment: Weigh Na 2 S is dissolved in deionized water and configured as 0.08mol / L Na 2 S aqueous solution and transferred to the hydrothermal reactor, with the long Co(CO obtained in step 1 3 ) 0.35 Cl 0.20 (OH) 1.10 The substrate of the nanowires continues to serve as the substrate, immersed in the Na in the rea...

Embodiment 3

[0045] 1) Precursor formation: use an analytical balance to weigh Co(NO 3 ) 2 ·6H 2 O 、CO(NH 2 ) 2 , NH 4 Cl was dissolved in deionized water, stirred on a magnetic stirrer at room temperature to form a solution with uniform concentration; then transferred to a polytetrafluoroethylene-lined reactor, and the previously prepared nickel foam substrate was immersed in the reactor In the solution, and then placed in an oven at 100 ° C for 6 h, naturally cooled to room temperature. After the end, the substrate was taken out and washed and dried to obtain the precursor Co(CO 3 ) 0.35 Cl 0.20 (OH) 1.10 The substrate of the nanowires.

[0046] 2) Vulcanization treatment: Weigh Na 2 S is dissolved in deionized water and configured as 0.08mol / L Na 2 S aqueous solution and transferred to the hydrothermal reactor, with the long Co(CO obtained in step 1 3 ) 0.35 Cl 0.20 (OH) 1.10 The substrate of the nanowires continues to serve as the substrate, immersed in the Na in the rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com