Aluminum base gelling and curing agent, preparation method and application thereof

A technology of solidification and aluminum-based glue, applied in the field of aluminum-based glue coagulant and preparation field, can solve the problems of large amount of dredged sediment, few ways of resource utilization of solidified sediment, and difficulty in large-scale consumption, etc. The effect of reducing ecological damage and natural resource consumption, realizing large-scale safe treatment and disposal, and enhancing mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

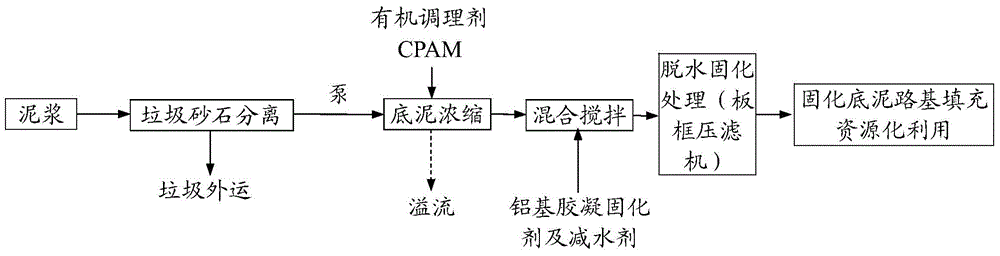

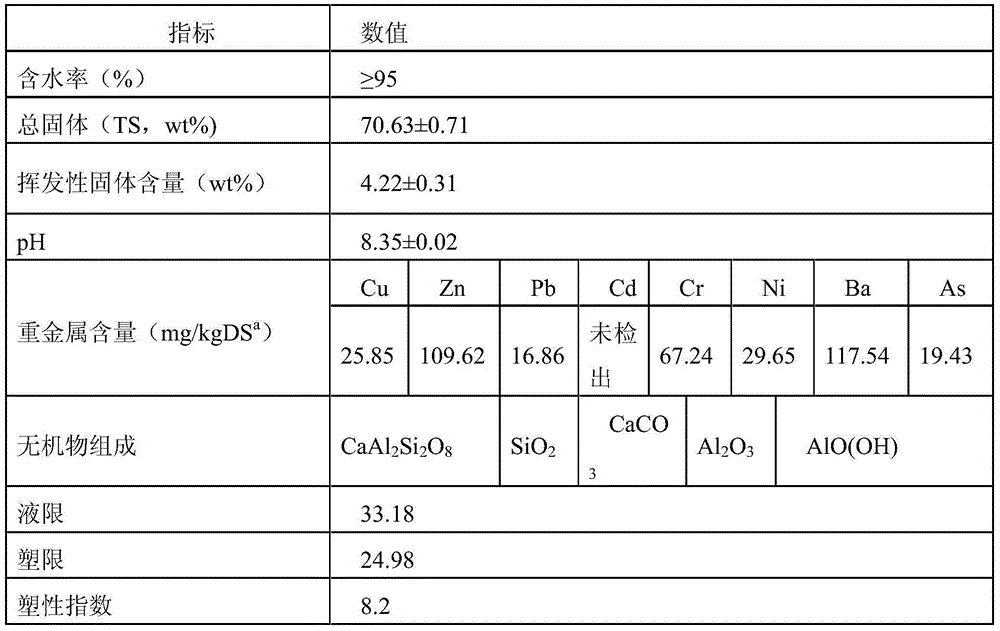

[0036] Solidification and modification treatment of river dredging sediment in a city in Jiaxing City

[0037] (1) Preparation of aluminum-based gelling and curing agent

[0038] The laboratory preparation method adopts the falling cone method: grind calcium aluminate, sulfur-aluminum cement, and early-strength coagulant with a mass ratio of 3:6.5:0.5, pass through a 0.08mm sieve, mix and accumulate into a cone, and then flatten it. The surrounding samples are piled up to the center to form a cone again and then flattened, and this is repeated several times to obtain an aluminum-based gelling curing agent;

[0039] The industrial preparation method uses a ball mill to fully grind calcium aluminate, sulfur-aluminum cement, and early-strength coagulant respectively. After passing through a 2mm sieve, the mass ratio of calcium aluminate:sulfo-aluminum cement:early-strength coagulant is 3: 6.5:0.5 directly added to the dredged sediment. Early strength coagulant is anhydrous CaSO...

Embodiment 2

[0055] Example 2—Pilot test of solidification and modification treatment of river dredged sediment in a certain city in Jiaxing City

[0056] (1) Preparation of aluminum-based gelling and curing agent

[0057] The laboratory preparation method adopts the falling cone method: grind calcium aluminate, sulfur-aluminum cement, and early-strength coagulant with a mass ratio of 1:8.5:0.5, pass through a 0.08mm sieve, mix and accumulate into a conical shape, and then flatten it. The surrounding samples are piled up to the center to form a cone again and then flattened, and this is repeated several times to obtain an aluminum-based gelling curing agent;

[0058] The industrial preparation method uses a ball mill to fully grind calcium aluminate, sulfur-aluminum cement, and early-strength coagulant respectively. After passing through a 2mm sieve, the mass ratio of calcium aluminate:sulfo-aluminum cement:early-strength coagulant is 1: 8.5:0.5 Add directly to the dredged sediment. Earl...

Embodiment 3

[0070] Example 3 - Solidification and modification treatment of dredged sediment in a certain city in Shanghai

[0071] (1) Preparation of aluminum-based gelling and curing agent

[0072] The laboratory preparation method adopts the falling cone method: grind calcium aluminate, sulfur-aluminum cement, and early-strength coagulant with a mass ratio of 2:7.5:0.5, pass through a 0.08mm sieve, mix and accumulate into a cone, and then flatten it. The surrounding samples are piled up to the center to form a cone again and then flattened, and this is repeated several times to obtain an aluminum-based gelling curing agent;

[0073] The industrial preparation method uses a ball mill to fully grind calcium aluminate, sulfur-aluminum cement, and early-strength coagulant respectively. After passing through a 2mm sieve, the mass ratio of calcium aluminate:sulfo-aluminum cement:early-strength coagulant is 2: 7.5:0.5 directly added to the dredged sediment. The early strength coagulant is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com