Preparation method of modified fluorine-containing acrylic superhydrophobic resin emulsion

A technology of resin emulsion and acrylic acid, applied in coating and other directions, can solve the problems of low success rate of in-situ polymerization method, difficult to meet the growing demand for high-performance fluorine-containing acrylic superhydrophobic resin, etc., and achieve low cost and high success rate. , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Prepare modified fluorine-containing acrylic acid superhydrophobic resin emulsion, the steps are as follows:

[0034] a. Throw ethyl orthosilicate and methyltriethoxysilane into the alcohol solution at a molar ratio of 0.1, raise the temperature to 70°C, and stir for 4 hours, then add emulsifier OP-10 and polyethylene Alcohol, continue to stir until the material is completely dissolved, stop heating and leave to age at room temperature for 10h;

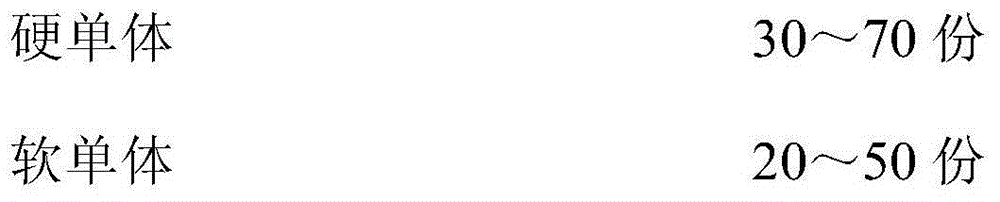

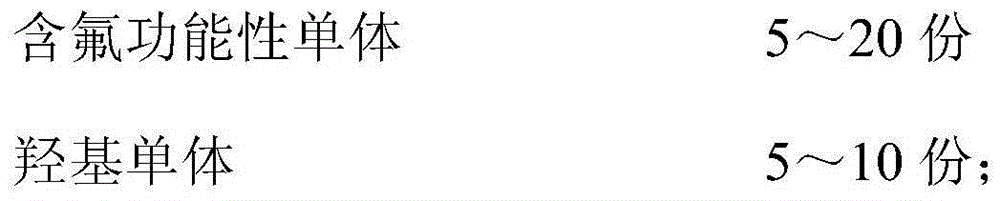

[0035] b. Mix the following monomers by weight uniformly to obtain mixed monomers:

[0036]

[0037]c. Warm up the solution prepared in step a to 75°C, then add the mixed monomer and 1 / 4 of the initiator potassium persulfate solution dropwise at the same time, control the dropping time for 3 hours, and then add 1 / 4 of the solution at one time Initiator solution, continue to keep warm for 0.5h, then add the rest of the initiator solution at one time, and raise the temperature of the solution to 85°C, continue to keep warm fo...

Embodiment 2

[0039] Prepare modified fluorine-containing acrylic acid superhydrophobic resin emulsion, the steps are as follows:

[0040] a. Throw ethyl orthosilicate and dimethyldiethoxysilane into the alcohol solution at a molar ratio of 0.9, raise the temperature to 90°C, and stir for 6 hours, then add emulsifier OP-10, ten Dialkyl sodium sulfate and polyvinyl alcohol, continue to stir until the materials are completely dissolved, stop heating and leave to age at room temperature for 20h;

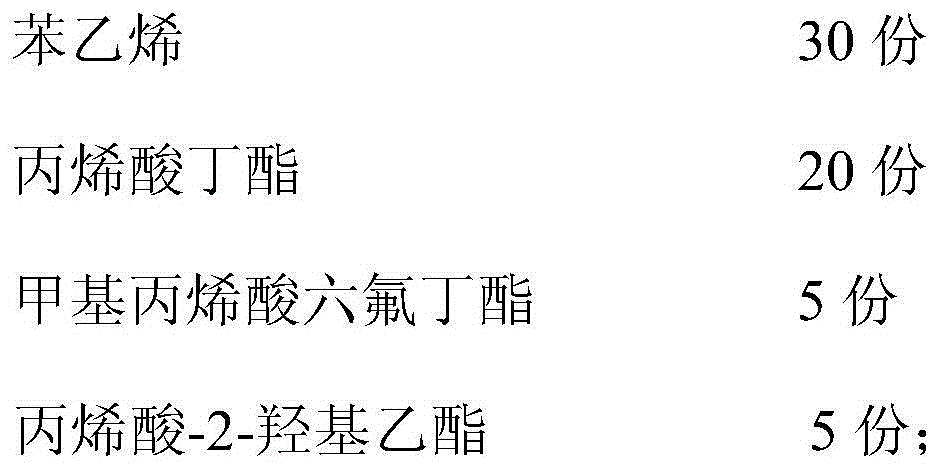

[0041] b. Mix the following monomers by weight uniformly to obtain mixed monomers:

[0042]

[0043] c. Warm up the solution prepared in step a to 85°C, then add the mixed monomer and 1 / 2 of the initiator potassium persulfate solution dropwise at the same time, control the dropping time for 5 hours, and then add 1 / 3 of the solution at one time Initiator solution, continue to keep warm for 1 hour, then add the rest of the initiator solution at one time, and raise the temperature of the solution to...

Embodiment 3

[0045] Prepare modified fluorine-containing acrylic acid superhydrophobic resin emulsion, the steps are as follows:

[0046] a. Throw ethyl orthosilicate, methyltriethoxysilane, dimethyldiethoxysilane and trimethylchlorosilane into the alcohol solution at a molar ratio of 0.5:0.5:0.25:0.25 , heat up to 80°C, and stir for 5 hours, then add emulsifier OP-10, AES, sodium lauryl sulfate and polyvinyl alcohol, continue to stir until the material is completely dissolved, stop heating and stand at room temperature for 15 hours ;

[0047] b. Mix the following monomers by weight uniformly to obtain mixed monomers:

[0048]

[0049] c. Warm up the solution prepared in step a to 80°C, then add the mixed monomer and 1 / 3 of the mixed initiator solution dropwise at the same time (the mass ratio of sodium persulfate and ammonium persulfate in the initiator solution is 1:2) , control the dropping time for 4 hours, then add 30% of the initiator solution at one time, continue the heat pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com