A kind of preparation method of lead-containing electrolyte

A preparation method and technology of lead electrolyte, which are applied to the improvement of process efficiency, photographic technology, instruments, etc., can solve the problems of shortening boiler life, difficult waste water treatment, low crude lead yield, etc., to save production costs, realize The effect of reuse, energy consumption and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Get 500g dry lead oxide scum, which contains 88.22% lead, 0.1907% antimony, 0.23% copper, and 0.0015% bismuth. The specific steps for preparing lead-containing electrolyte are as follows:

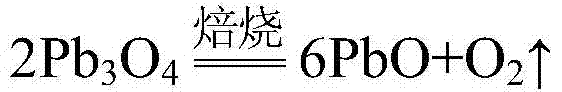

[0028] (1) roasting: put the lead peroxide scum into an electric furnace for roasting, and roast for 2 hours at a temperature of 550°C;

[0029] (2) One-time water washing: crush and ball-mill the roasted product obtained in step (1) to below 120 mesh, add water, the liquid-solid mass ratio is 6:1, control the temperature at 70°C, and stir for 2 hours until the pH is detected as 11-12, After filtering, the primary washing water enters the three-effect evaporator system;

[0030] (3) Secondary water washing: add water to the washed slag obtained in step (2) again, the liquid-solid mass ratio is 8:1, the temperature is 60°C, stir for 3 hours until the pH is 7-9, and the secondary washing water is returned once after filtering The washing water enters the three-effect evaporator system...

Embodiment 2

[0035] Get 1000g dry lead oxide scum, which contains 90.01% lead, 0.3673% antimony, 0.0014% copper, and 0.0006% bismuth. The specific steps for preparing lead-containing electrolyte are as follows:

[0036] (1) roasting: put the lead peroxide scum into an electric furnace for roasting, and roast for 4 hours at a temperature of 500°C;

[0037] (2) One-time water washing: crush and ball-mill the roasted product obtained in step (1) to below 120 mesh, add water, the liquid-solid mass ratio is 3:1, control the temperature at 90°C, and stir for 3 hours until the pH is detected as 11-12, After filtering, the primary washing water enters the three-effect evaporator system;

[0038] (3) Secondary water washing: add water to the washed slag obtained in step (2) again, the liquid-solid mass ratio is 4:1, the temperature is 80°C, and stir for 2 hours until the pH is detected as 7-9, and the secondary washing water is returned once after filtering The washing water enters the three-effec...

Embodiment 3

[0042] Get 500g dry lead oxide scum, which contains 87.56% lead, 0.2358% antimony, 0.0019% copper, and 0.0010% bismuth. The specific steps for preparing lead-containing electrolyte are as follows:

[0043] (1) roasting: put the lead peroxide scum into an electric furnace for roasting, and roast for 3 hours at a temperature of 530°C;

[0044] (2) One-time water washing: crush and ball-mill the roasted product obtained in step (1) to below 120 mesh, add water, the liquid-solid mass ratio is 4:1, control the temperature at 85°C, and stir for 2 hours until the pH is detected as 11-12, After filtering, the primary washing water enters the three-effect evaporator system;

[0045] (3) Secondary water washing: add water to the washed slag obtained in step (2) again, the liquid-solid mass ratio is 5:1, the temperature is 75°C, and stir for 3 hours until the pH is 7-9, and the secondary washing water is returned once after filtering The washing water enters the three-effect evaporator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com