Oil agent for improving morphological stability of textile

A technology of stability and textiles, applied in textiles and papermaking, fiber types, fiber processing, etc., can solve problems such as poor morphological stability, and achieve the effects of strong deformation recovery force, strong friction and cohesion force, and good morphological stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

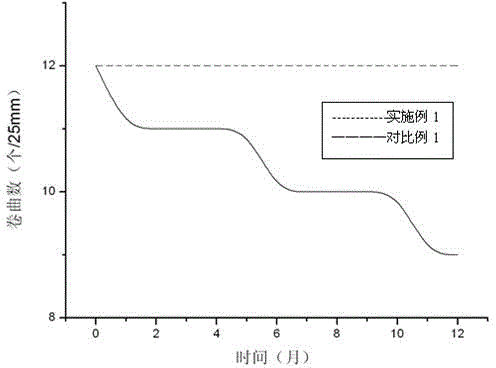

Embodiment 1

[0047]After the oil agent of the present invention is applied to the dry heat setting process of spandex textiles, the dry heat setting equipment is the M-751 series setting machine, and the radial tension of the textiles can be reduced by adopting super-speed feeding, which is beneficial to the expansion; To achieve a certain retraction effect, the needle clip chain expansion device gradually expands the fabric by piercing the edge of the cloth with two ring-shaped needle clip chains. After the textiles are pinned, they are then heated in a hot drying room and treated at 160°C for 20 seconds to achieve the purpose of heat setting. Within 8 hours of heat setting, immerse the textile in the following oil for dilution. When the oil is used, it is mixed with 60°C water and diluted 5 times. The proportion of oil and oil by weight is as follows:

[0048] 30 parts of ethylene oxide polyether,

Embodiment 2

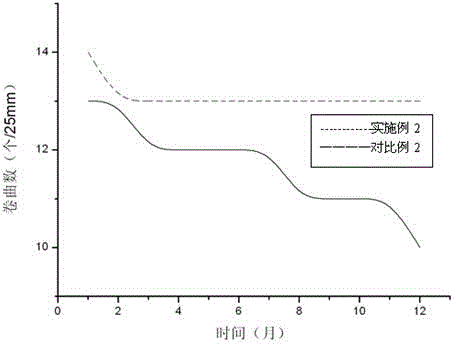

[0060] After the oil agent of the present invention is applied to the dry heat setting process of polyester textiles, the dry heat setting equipment is the M-751 series setting machine, and the radial tension of the textiles can be reduced by adopting super-speed feeding, which is beneficial to the expansion; To achieve a certain retraction effect, the needle clip chain expansion device gradually expands the fabric by piercing the edge of the cloth with two ring-shaped needle clip chains. After the textiles are pinned, they are then heated in a drying room and treated at 170°C for 40 seconds to achieve heat setting. Within 4 hours of heat setting, immerse the textile in the following dilution of the oil agent, the oil agent is diluted 8 times with 50°C water, and the proportion of the oil agent and oil agent by weight is as follows:

[0061] 40 parts of ethylene oxide polyether,

Embodiment 3

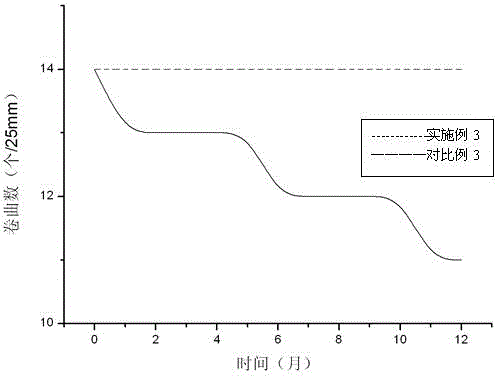

[0073] After the oil agent of the present invention is applied to the wet heat setting process of nylon textiles, steam setting is used, the needled textiles are wound on porous vacuumable rollers, and put into steaming for treatment at a temperature of 130° C. for 25 minutes. Within 1 hour of heat setting, the textile is sprayed with a dilute oil for improving the shape stability of the textile. The oil is diluted 15 times with 50°C water, and the proportion of the oil and oil by weight is as follows:

[0074] 34 parts of ethylene oxide polyether,

[0075] 26 parts of sodium lauryl phosphate,

[0076] 20 parts of potassium alkyl ether sulfate,

[0077] 12 parts of triolein,

[0078] 10 parts of succinic acid penetrant,

[0079] Emulsifier OP-10 5 parts,

[0080] 5 parts of alkyldiethanolamine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com