Method for preparing field emission cathode of nano carbon sheet-silicon nanowire composite structure

A field emission cathode and silicon nanowire technology, which is applied in the preparation and application of nanomaterials, can solve the problems of poor field electron emission ability and difficult to work stably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

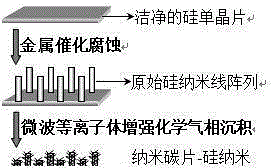

[0035] (1) Preparation of clean silicon wafer substrate:

[0036] First, cut the silicon wafer into small pieces of 2cm×2cm, clean them with ultrasonic (50W) in deionized water, acetone and absolute ethanol for 10 minutes, and then put the silicon wafer into hydrofluoric acid with a volume ratio of 4% for 5 minutes. Minutes for clean, contamination-free substrates free of silica overlays.

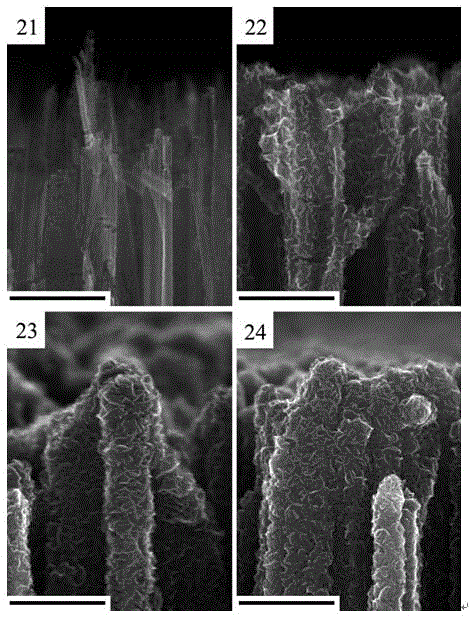

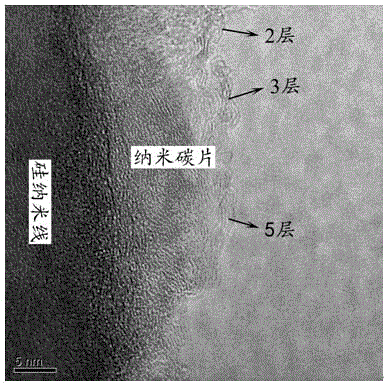

[0037] (2) Fabrication of silicon nanowire arrays by metal-catalyzed corrosion method:

[0038] The metal-catalyzed corrosion method is a conventional method for preparing silicon nanowire arrays: firstly, the cleaned silicon wafer is placed in a AgNO 3 :HF:H 2 O = 2:10:38 solution soaked for 1 minute, used to deposit the silver catalyst; then immediately put the silicon wafer deposited with the silver catalyst particles into the volume ratio of H 2 o 2 :HF:H 2 The silicon nanowires were grown by soaking and etching in the solution of O=1:10:39 for 45 minutes, and the silicon nanowire ...

Embodiment 2

[0046] (1) Preparation of clean silicon wafer substrate:

[0047] First, cut the silicon wafer into small pieces of 2cm×2cm, clean them with ultrasonic (50W) in deionized water, acetone and absolute ethanol for 10 minutes, and then put the silicon wafer into hydrofluoric acid with a volume ratio of 4% for 5 minutes. Minutes for clean, contamination-free substrates free of silica overlays.

[0048] (2) Fabrication of silicon nanowire arrays by metal-catalyzed corrosion method:

[0049] The metal-catalyzed corrosion method is a conventional method for preparing silicon nanowire arrays: firstly, the cleaned silicon wafer is placed in a AgNO 3 :HF:H 2 O = 2:10:38 solution soaked for 1 minute, used to deposit the silver catalyst; then immediately put the silicon wafer deposited with the silver catalyst particles into the volume ratio of H 2 o 2 :HF:H 2 The silicon nanowires were grown by soaking and etching in the solution of O=1:10:39 for 45 minutes, and the silicon nanowire ...

Embodiment 3

[0057] (1) Preparation of clean silicon wafer substrate:

[0058] First, cut the silicon wafer into small pieces of 2cm×2cm, clean them with ultrasonic (50W) in deionized water, acetone and absolute ethanol for 10 minutes, and then put the silicon wafer into hydrofluoric acid with a volume ratio of 4% for 5 minutes. Minutes for clean, contamination-free substrates free of silica overlays.

[0059] (2) Fabrication of silicon nanowire arrays by metal-catalyzed corrosion method:

[0060] The metal-catalyzed corrosion method is a conventional method for preparing silicon nanowire arrays: firstly, the cleaned silicon wafer is placed in a AgNO 3 :HF:H 2 O = 2:10:38 solution soaked for 1 minute, used to deposit the silver catalyst; then immediately put the silicon wafer deposited with the silver catalyst particles into the volume ratio of H 2 o 2 :HF:H 2 The silicon nanowires were grown by soaking and etching in the solution of O=1:10:39 for 45 minutes, and the silicon nanowire ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Maximum field emission current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com