Preparation method of antibacterial attapulgite zearalenone adsorbent

A technology of zearalenone and attapulgite, which is applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of reducing the amount of antibiotics used, the high price of mold removers, and the difficulty in removal, and achieves a reduction in the amount of use. Conducive to mass production and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

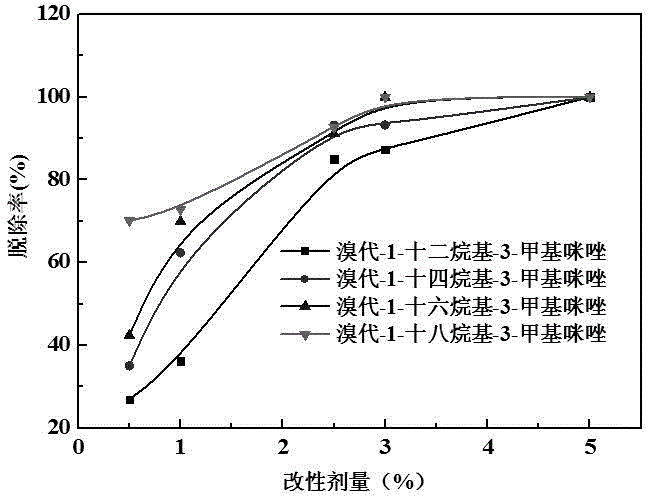

[0025] Embodiment 1: take 100g attapulgite clay and be mixed with the ore slurry that quality is 20%, then add the composite acid modifier of attapulgite clay quality 20% (wherein, the proportioning of acid modifier is that phosphoric acid accounts for 30% , formic acid accounted for 10%, citric acid accounted for 30%, fumaric acid accounted for 30%), stirred at room temperature for 4 hours, passed through a 200-mesh sieve to remove quartz impurities, then added C12mimBr with 15% of the mass of attapulgite clay, and gradually heated to 40 ° C for 4 hours Afterwards, centrifuge, wash with water and ethanol in sequence, dry at 80°C for 4 hours, and then pulverize to obtain attapulgite zearalenone adsorbent with antibacterial function.

Embodiment 2

[0026] Embodiment 2: take 100g attapulgite clay and be mixed with the ore slurry that quality is 20%, then add attapulgite clay quality 10% composite acid modifier (wherein, the proportioning of acid modifier is that phosphoric acid accounts for 30%, Lactic acid accounted for 30%, citric acid accounted for 20%, fumaric acid accounted for 20%), stirred at room temperature for 4 hours, passed through a 200-mesh sieve to remove quartz impurities, then added C14mimBr with 10% of the mass of attapulgite clay, gradually heated to 60°C for 6 hours, and then centrifuged , washed with water and ethanol in turn, dried at 105°C for 4 hours, and pulverized to obtain attapulgite zearalenone adsorbent with antibacterial function.

Embodiment 3

[0027] Embodiment 3: take 100g attapulgite clay and be mixed with the ore slurry that quality is 20%, then add attapulgite clay quality 5% composite acid modifier (wherein, the proportioning of acid modifier is that sulfuric acid accounts for 30%, Formic acid accounted for 20%, malic acid accounted for 30%, succinic acid accounted for 20%), stirred at room temperature for 4 hours, passed through a 200-mesh sieve to remove quartz impurities, and then added attapulgite clay with 5% mass of [C16mim][PF 6 - ], gradually heated to 80°C for 8 hours, centrifuged, washed with water and ethanol in turn, dried at 105°C for 4 hours, and then pulverized to obtain attapulgite zearalenone adsorbent with antibacterial function.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com