Method for preparing graphite-phase carbon nitride nanosheets by using solution phase

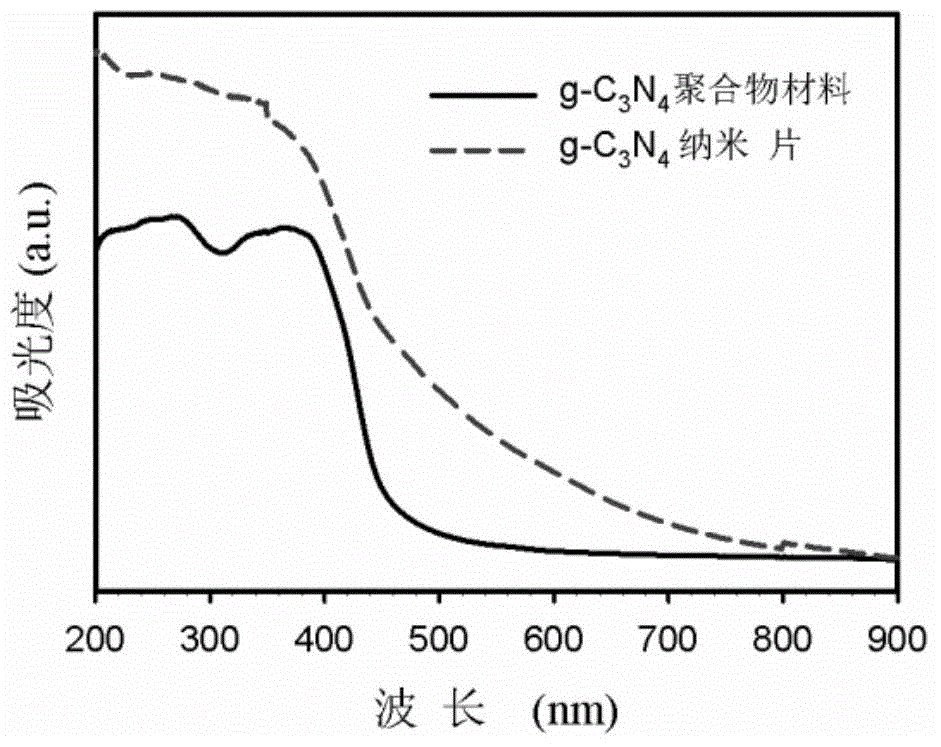

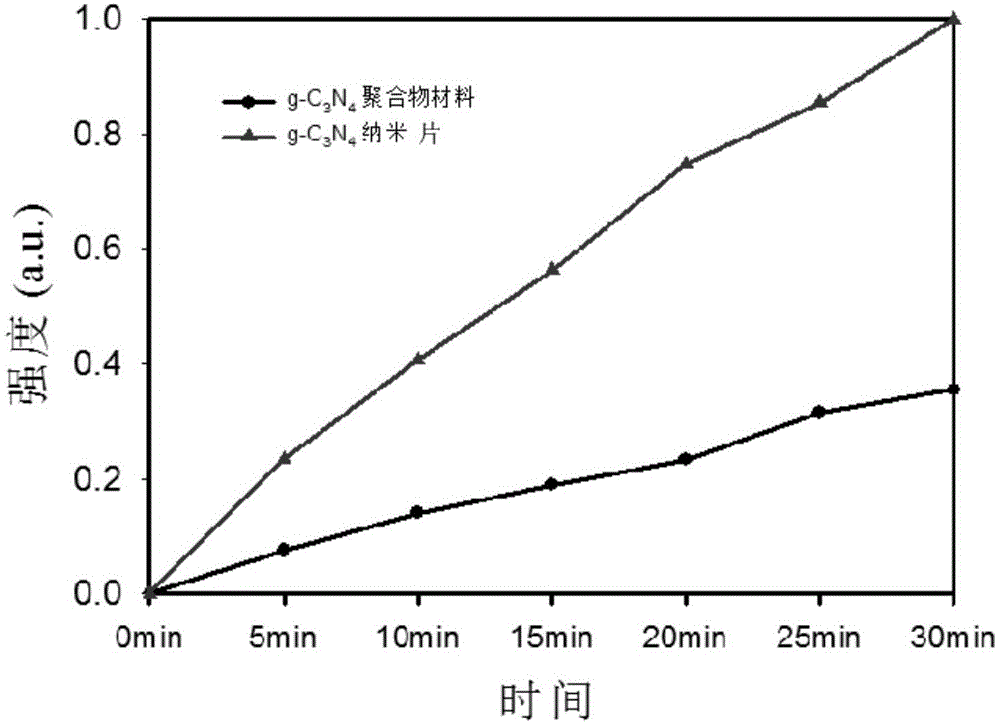

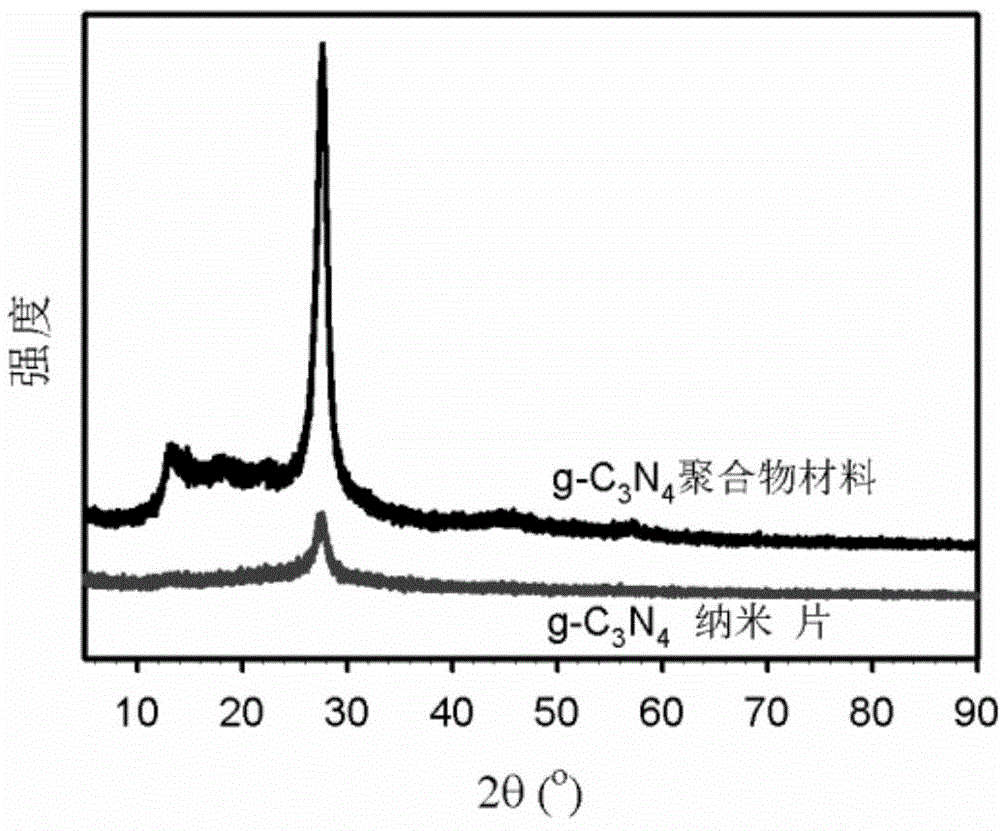

A graphitic carbon nitride and nanosheet technology, applied in nanotechnology, nanotechnology, nitrogen and non-metallic compounds, etc., can solve the problems of large thickness, poor dispersibility, and low nanosheet efficiency, and achieve high preparation efficiency and dispersion. Good performance and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A solution-phase preparation of graphitic carbon nitride (g-C 3 N 4 ) a method for nanosheets, comprising the following steps:

[0029] Add 10g of dicyandiamide to a 50mL ceramic crucible with a lid, place the crucible in a muffle furnace, raise it from room temperature to 550°C at a rate of 2.5°C / min, and keep the temperature constant for two hours. After calcination, cool to room temperature, grind the sample in an agate mortar to obtain a yellow powder, namely g-C 3 N 4 polymer material. Under the condition of nitrogen protection, weigh 108mg g-C 3 N 4 The polymer material was added to 120mL of freshly dried THF solution, ultrasonicated for 5min, then 0.55g of metal lithium and 5.08g of naphthalene were added to the dispersion, the solution turned dark green and stirred continuously for one hour, and then an autoinjector was used to inject 10mL / Add 1-bromododecane to the above solution at a speed of h until the green color of the solution disappears, and conti...

Embodiment 2

[0032] Add 8.43g of dicyandiamide to a 50mL ceramic crucible with a lid, place the crucible in a muffle furnace, raise it from room temperature to 550°C at a rate of 2.5°C / min, and keep the temperature constant for two hours. After calcination, cool to room temperature, grind the sample in an agate mortar to obtain a yellow powder, namely g-C 3 N 4 polymer material. Under the condition of nitrogen protection, weigh 71.2mg g-C 3 N 4 Add the polymer material to 100mL of freshly dried tetrahydrofuran solution, ultrasonicate for 5min, then add 0.81g of lithium metal and 5.22g of naphthalene to the dispersion, the solution turns dark green and then continue to stir for one hour, then use an automatic injector to inject 10mL / Add 1-bromo-n-butane to the above solution at a speed of h until the green color of the solution disappears, and continue to react for 12 hours under the protection of nitrogen. After the reaction, add ethanol to the above reactant to remove unreacted lithi...

Embodiment 3

[0034] Add 10g of dicyandiamide to a 50mL ceramic crucible with a lid, place the crucible in a muffle furnace, raise it from room temperature to 550°C at a rate of 2.5°C / min, and keep the temperature constant for two hours. After calcination, cool to room temperature, grind the sample in an agate mortar to obtain a yellow powder, namely g-C 3 N 4 polymer material. Under the condition of nitrogen protection, weigh 368mg g-C 3 N 4 The polymer material was added to 120mL of freshly dried THF solution, ultrasonicated for 5min, then 0.21g of metal lithium and 2.56g of naphthalene were added to the dispersion, the solution turned dark green and stirred continuously for one hour, and then an autoinjector was used to inject 10mL / Add 1-bromo-n-hexane to the above solution at a speed of h until the green color of the solution disappears, and continue to react for 12 hours under the protection of nitrogen. After the reaction, add ethanol to the above reactant to remove unreacted lit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com