Fast and effective treatment method for acid waste water from nonferrous metal mines

A technology for effective treatment of acidic wastewater from mines. It is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. It can solve the problems of large floor space, waste of resources and large investment costs , to achieve the effect of reducing the amount of construction, shortening the construction period, and reducing project investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

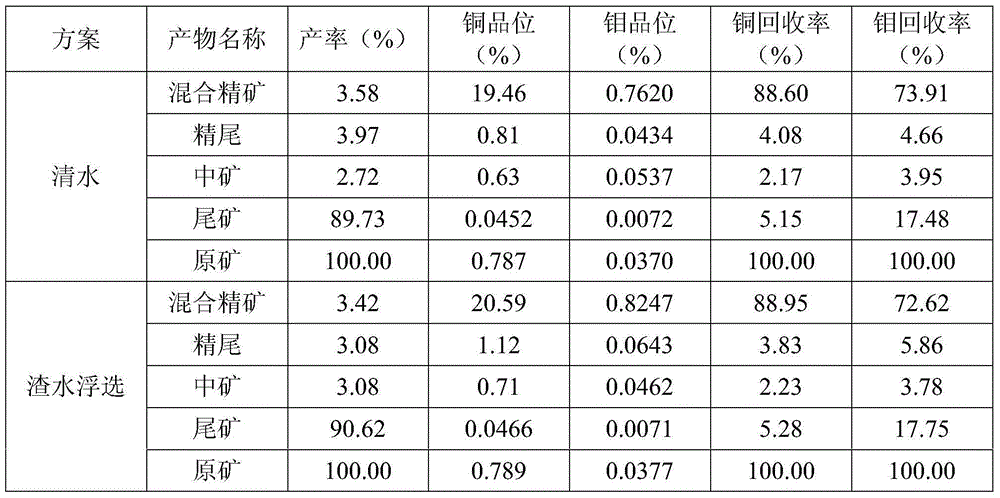

[0028] Acidic wastewater from a non-ferrous metal mine, pH 2.6, Cu 263.51mg / L, Fe 1235.47mg / L, Zn 4.52mg / L, Ni 6.64mg / L, As 2.12mg / L, SO 4 2- It is 15360.43mg / L, and also contains trace amounts of other heavy metal ions. Take 5L of waste water and place it in the stirring tank, start the stirring, add lime milk with a mass concentration of 10% to adjust the pH of the waste water to 3.5-4.0, react for 20 minutes, and then pass the slag-water mixture into the vulcanization reaction stirring tank, Add 25 mL of sodium sulfide solution with a mass concentration of 10% and stir for 30 minutes, then add milk of lime with a mass concentration of 10% for neutralization reaction for 30 minutes, adjust the pH to 8.0, and neutralize the neutralized slag after neutralization by 1.2% by mass The percent is mixed with the raw ore, put into the grinding machine to grind the ore, and then the flotation test is carried out. The neutralization liquid after neutralization treatment is all used f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com