Antifogging film material and preparation method thereof

A film material, anti-fog technology, applied in the direction of coating, can solve the problems of affecting the light transmittance, danger, fogging and other problems of the film, and achieve the effects of simple preparation method, good film-forming property, and convenient material acquisition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

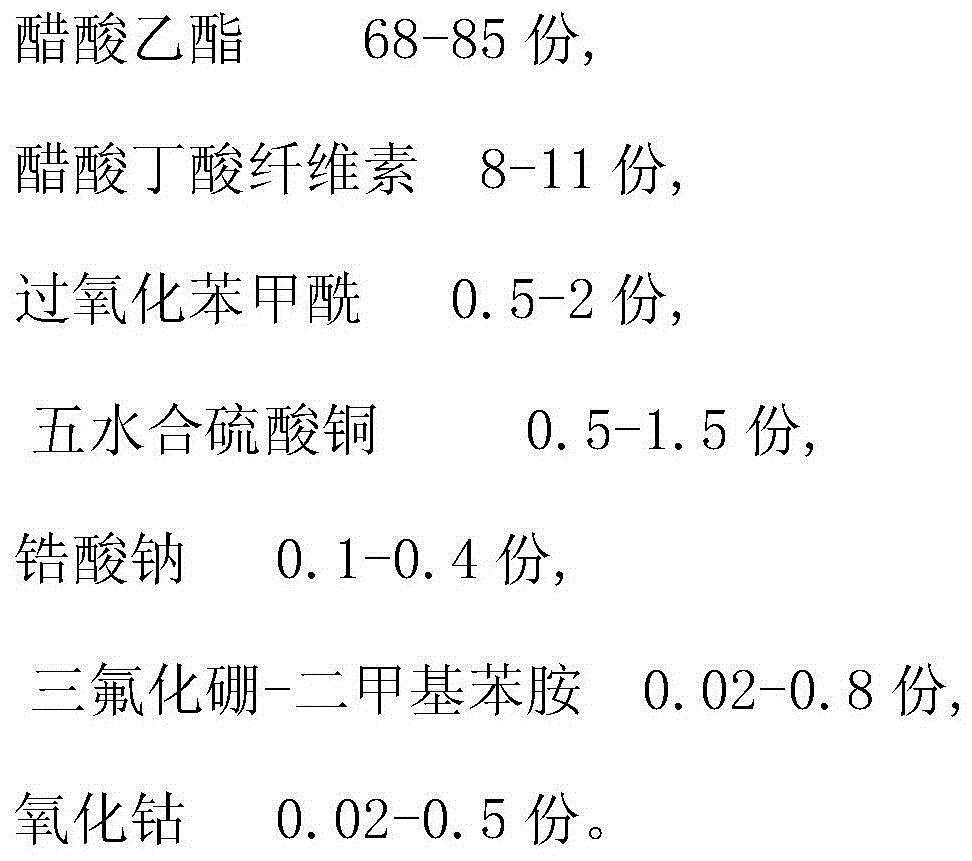

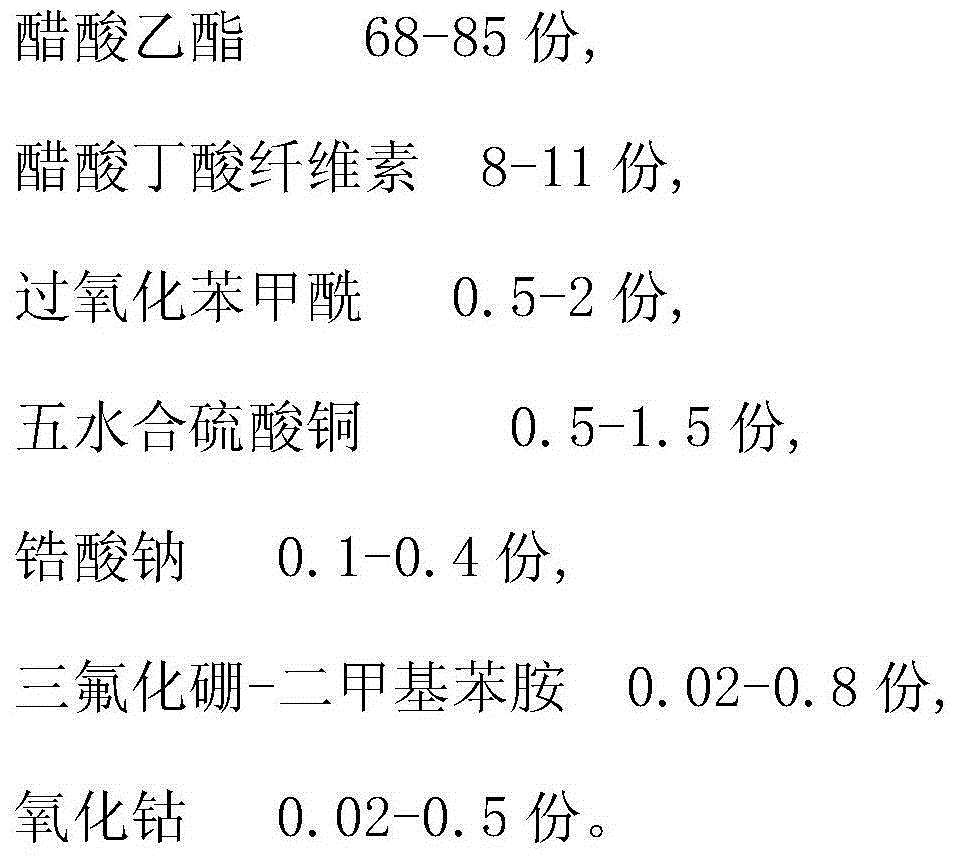

Method used

Image

Examples

Embodiment 1

[0022] (1) 68kg of ethyl acetate, 8kg of cellulose acetate butyrate, 0.5kg of benzoyl peroxide, 0.5kg of copper sulfate pentahydrate, 0.1kg of sodium zirconate, and 0.02kg of cobalt oxide were stirred evenly;

[0023] (2) Add in a high-pressure homogenizer with a pressure of 11Mpa and a temperature of 75°C, mix for 12 minutes, add 0.02kg of boron trifluoride-dimethylaniline, stir for 10 minutes at 75°C under nitrogen, degas, pour In a flat mold, dry in an oven at 60° C. for 4 hours, and demold to obtain an anti-fog film material.

Embodiment 2

[0025] (1) 68kg of ethyl acetate, 11kg of cellulose acetate butyrate, 0.5kg of benzoyl peroxide, 0.5kg of copper sulfate pentahydrate, 0.1kg of sodium zirconate, and 0.02kg of cobalt oxide were stirred evenly;

[0026] (2) Add in a high-pressure homogenizer with a pressure of 11Mpa and a temperature of 75°C, mix for 12 minutes, add 0.02kg of boron trifluoride-dimethylaniline, stir for 10 minutes at 75°C under nitrogen, degas, pour In a flat mold, dry in an oven at 60° C. for 4 hours, and demold to obtain an anti-fog film material.

Embodiment 3

[0028] (1) 85kg of ethyl acetate, 11kg of cellulose acetate butyrate, 2kg of benzoyl peroxide, 1.5kg of copper sulfate pentahydrate, 0.4kg of sodium zirconate, and 0.5kg of cobalt oxide were stirred evenly;

[0029] (2) Add to a high pressure homogenizer with a pressure of 15Mpa and a temperature of 95°C, mix for 18 minutes, add 0.04kg of tetraethylenepentamine, 0.6kg of octamethylcyclotetrasiloxane and bis-(phenyldimethylsiloxane) 1.2kg of alkane)methylsilanol, 0.02kg of boron trifluoride-dimethylaniline, stirred at 90°C for 15 minutes under nitrogen, degassed, poured into a flat mold, and dried in an oven at 65°C for 6 hour, demoulding to obtain the anti-fog film material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com