A method for joint treatment of ink waste liquid and metal pickling waste liquid

A combined treatment and metal acid technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as difficult dehydration, achieve simple method, high dehydration efficiency, and structural dense effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

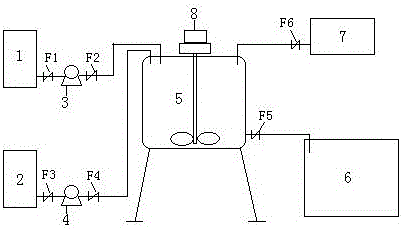

[0018] Embodiment 1 refers to figure 1

[0019] The invention provides a method for joint treatment of ink waste liquid and metal pickling waste liquid and its sludge dehydration. The water-based ink waste liquid is used for the flocculation, chelation and inorganic acid of metal ions in the metal pickling waste liquid. The role of the analysis makes the organic pollutants in the waste liquid change from hydrophilic to hydrophobic, and then the pollutants in the oily ink waste liquid are separated out under the condition of acidic aqueous solution and combined to wrap the water-based ink flocs, so that the pollution in the waste liquid Mutual coagulation, shrinkage, solidification and dehydration to form massive sludge, realizing the common removal of organic pollutants and metal ions. The massive sludge formed by shrinkage and aggregation has a compact structure, no other sludge dewatering equipment is needed, and the integration of waste liquid treatment and sludge dehydrat...

Embodiment 2

[0031] The black mixed water-based ink waste liquid in the water-based ink waste liquid storage tank 1 is pumped into the reaction curing dehydration tank 5 with the sewage pump 3 .

[0032] Add inorganic acid to the mixed water-based ink waste liquid in the reaction curing dehydration tank 5, and start the mixer 8 to stir the reaction at the same time, and adjust the pH value of the waste liquid to 1-2.

[0033] Pump the red oily ink waste liquid into the reaction curing dehydration tank 5 with the sewage pump 4, and keep stirring, so that the pollutants shrink and gather and dehydrate. After the lumpy sludge is formed, the supernatant liquid is discharged and the lumpy pollutants are taken out.

[0034] The invention provides a method for combined treatment of water-based ink waste liquid and oily ink waste liquid and sludge dehydration thereof, which mainly includes the following steps:

[0035] Step a. Mix black water-based ink waste (COD Cr : 400,000 mg / L; chromaticity:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com