Method for preparing polar modified ultrahighly-crosslinked resin and application of resin

An ultra-high cross-linked resin and polar technology, applied in separation methods, chemical instruments and methods, and other chemical processes, can solve problems such as unsatisfactory adsorption effects, achieve content reduction, increase adsorption capacity, and improve pore structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 1) Preparation of ternary copolymerization precursor resin:

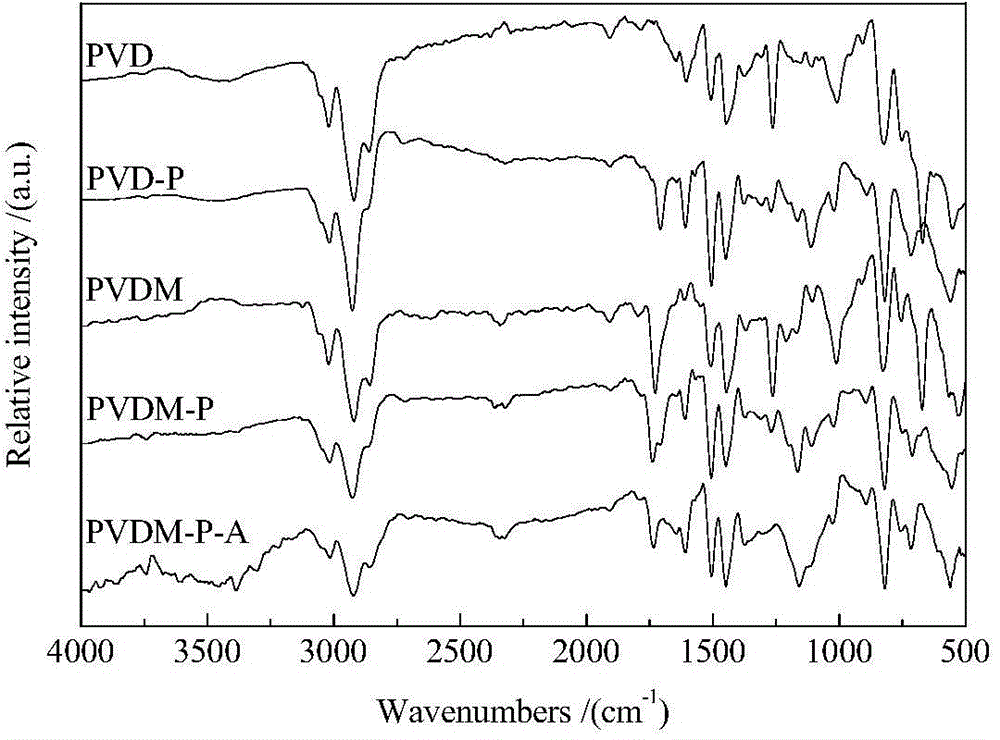

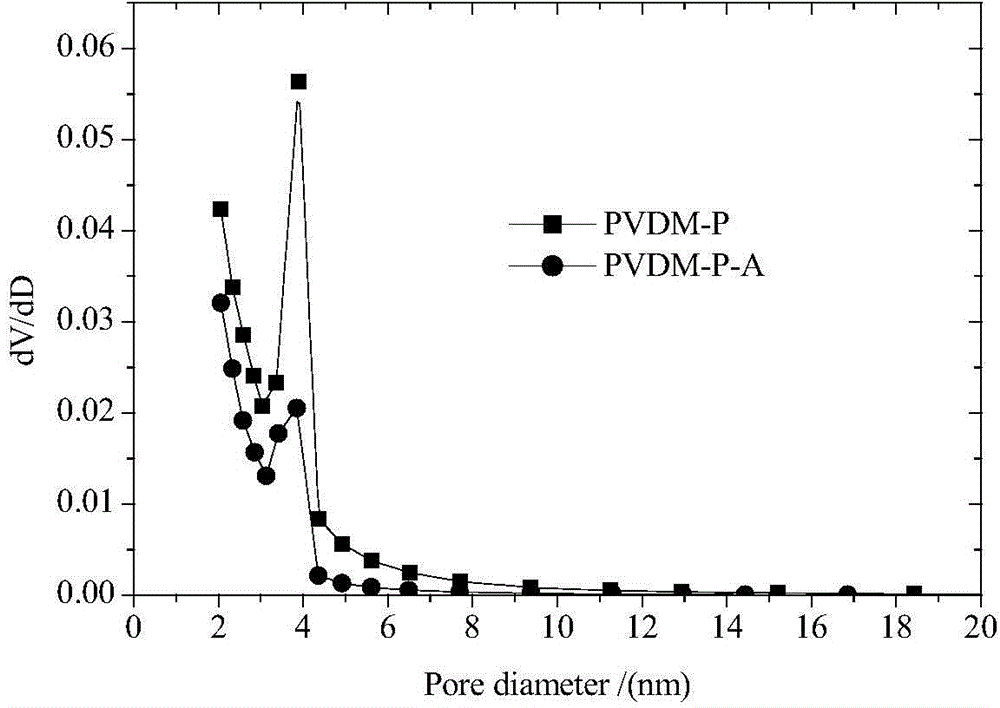

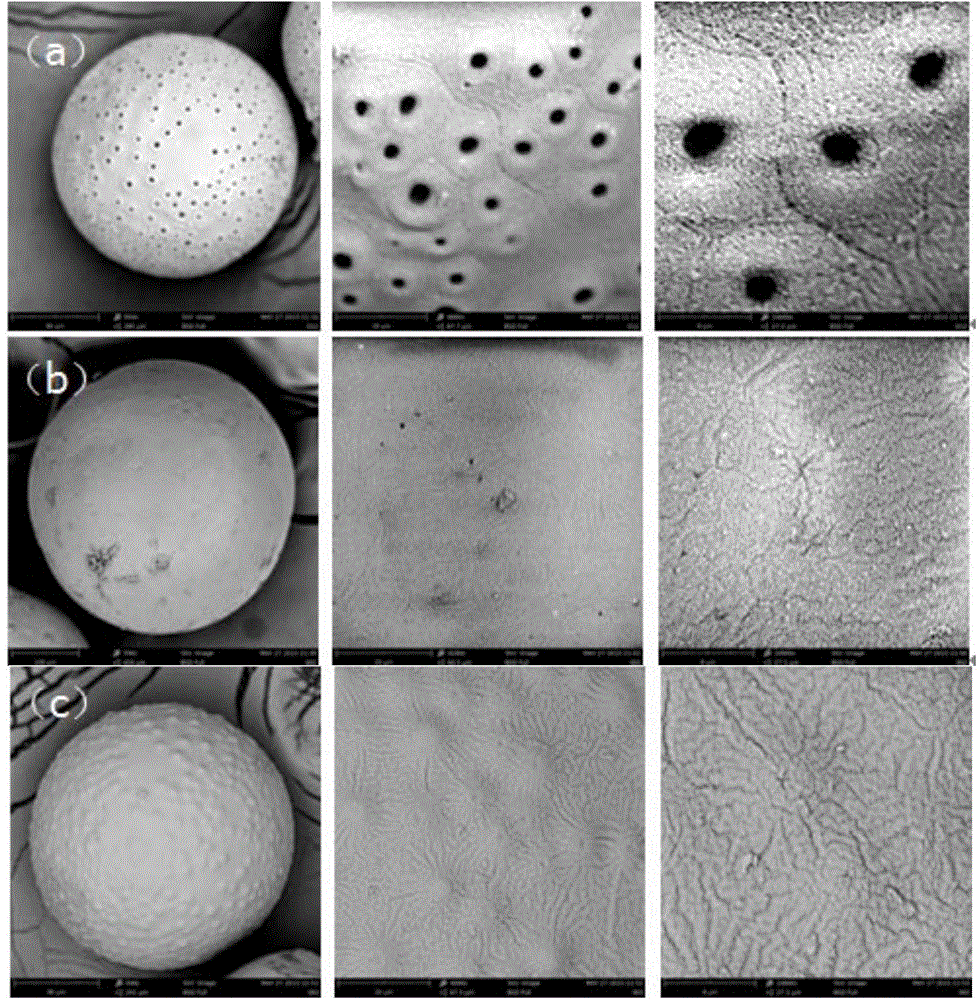

[0048] Place a 500mL three-necked round-bottomed flask on a water bath equipped with a mechanical stirrer, a condenser, and a thermometer. 1.0 g of oil phase divinylbenzene (DVB), 1.0 g of methyl acrylate (MA), 18.0 g of 4-vinylbenzyl chloride (VBC), 40.0 g of toluene, and 0.2 g of azobisisobutyronitrile (AIBN) were added. Heat to 45°C, adjust to a suitable stirring speed and stir for 30 minutes, raise the temperature to 75°C for 3 hours, raise the temperature to 85°C for 2 hours, and continue to raise the temperature to 95°C for 3 hours. After cooling, the resin was alternately washed with absolute ethanol, hot water, and cold water until the washing solution was clear, extracted with petroleum ether in a Soxhlet extractor for 12 hours, and dried in vacuum for 24 hours to obtain the ternary copolymerization precursor resin PVDM. The infrared characterization was as follows: figure 1 Shown, PVDM at 1263cm -...

Embodiment 2

[0057] 1) Preparation of ternary copolymerization precursor resin:

[0058] Place a 500mL three-necked round-bottomed flask on a water bath equipped with a mechanical stirrer, a condenser, and a thermometer. Added 2.0 g of divinylbenzene (DVB) oil phase, 2.0 g of methyl acrylate (MA), 16.0 g of 4-vinylbenzyl chloride (VBC), 50.0 g of toluene, and 0.2 g of benzoyl peroxide (BPO). Heat to 45°C, adjust to a suitable stirring speed and stir for 30 minutes, raise the temperature to 75°C for 3 hours, raise the temperature to 85°C for 2 hours, and continue to raise the temperature to 95°C for 3 hours. After cooling, alternately wash the resin with absolute ethanol, hot water, and cold water until the washing solution is clear, put it into a Soxhlet extractor and extract it with petroleum ether for 12 hours, and dry it in vacuum for 24 hours to obtain the ternary copolymerization precursor resin PVDM;

[0059] 2) Friedel-Crafts reaction:

[0060] Add 15g of ternary copolymerization ...

Embodiment 3

[0066] 1) Preparation of ternary copolymerization precursor resin:

[0067] Place a 500 mL three-necked round-bottomed flask on a water bath equipped with a mechanical stirrer, a condenser, and a thermometer, and first add the water phase (180 mL of distilled water, 20 mL of polyvinyl alcohol with a mass fraction of 1%, 10 drops of methylene blue), and 1.5 g of divinylbenzene (DVB) oil phase, 1.5 g of ethyl acrylate (EA), 17.0 g of 4-vinylbenzyl chloride (VBC), 45.0 g of toluene, and 0.3 g of benzoyl peroxide (BPO) were added. Heat to 45°C, adjust to a suitable stirring speed and stir for 30 minutes, raise the temperature to 75°C for 3 hours, raise the temperature to 85°C for 2 hours, and continue to raise the temperature to 95°C for 3 hours. After cooling, alternately wash the resin with absolute ethanol, hot water, and cold water until the washing solution is clear, put it into a Soxhlet extractor and extract it with petroleum ether for 12 hours, and dry it in vacuum for 24 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com