Stone seamless adhesive glue and preparation method thereof

An adhesive and seamless technology, applied in the direction of adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problems of small interface, unreachable seamlessness, and very high bonding strength requirements , to achieve uniform and stable colloidal state, improve bonding strength, and eliminate the effect of falling off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] A preparation method based on the above-mentioned stone seamless adhesive, comprising the following steps:

[0039] 1) Take the components according to the weight parts of the above-mentioned raw materials, and set aside;

[0040] 2) Stir the above components evenly at high speed under negative pressure with a vacuum degree of 0.08-0.1Mpa and a rotational speed of not less than 1500r / min. The stirring time is 30-45 minutes to obtain a stone seamless adhesive.

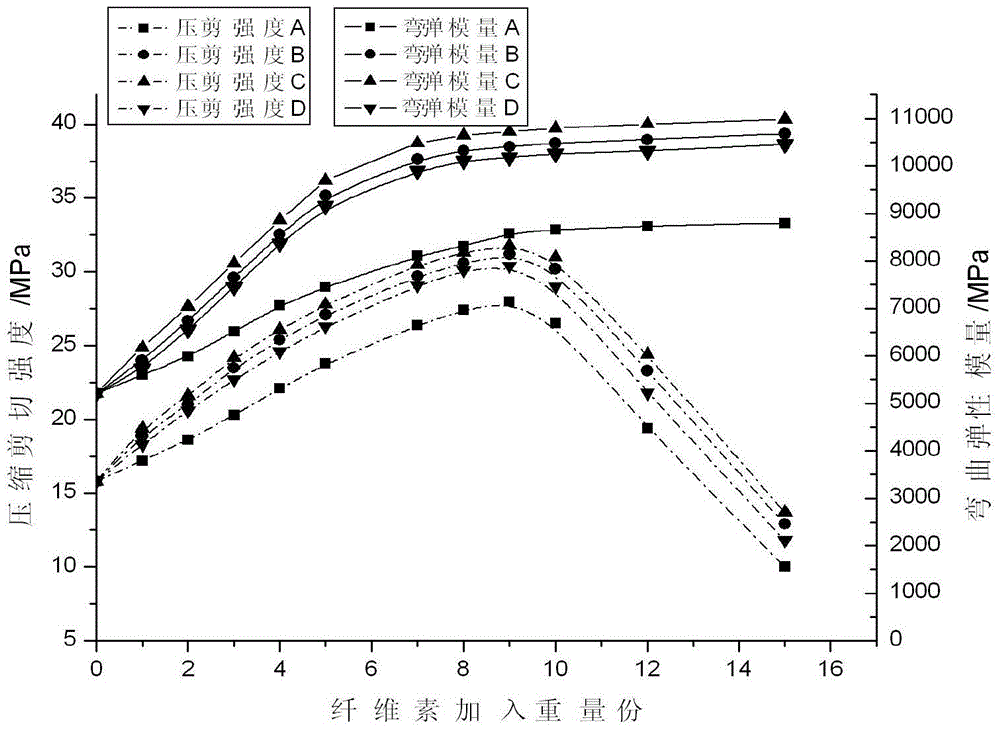

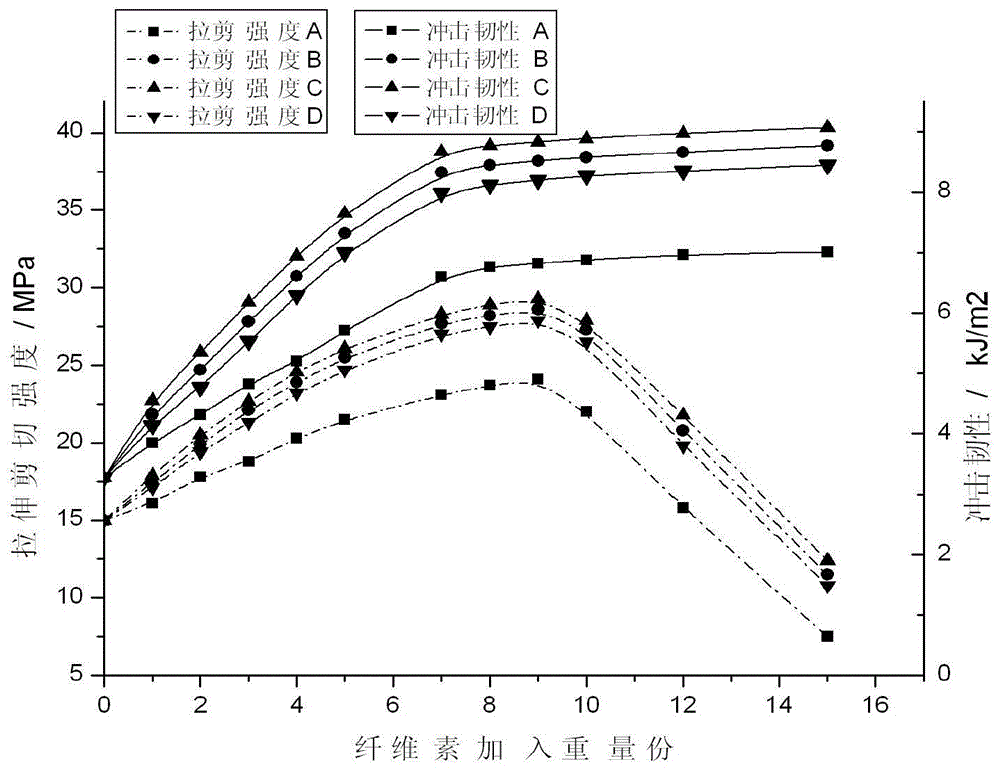

[0041] Adding cellulose substances in the present invention can obviously increase colloidal strength, and its reinforcing mechanism is as follows: cellulose has very high mechanical modulus and strength usually, when using unsaturated polyester resin as matrix, when reinforcing with cellulose, The matrix can produce plasticity under the action of stress, and the load is transmitted to the fiber, and the fiber bears the load. The matrix bonds and fixes the fibers and protects the fibers in a stable state, thus f...

Embodiment 1

[0127] Embodiment 1 (by weight parts)

[0128] The stone material seamless bonding glue is calculated by weight parts, consists of 100 parts of pre-accelerated unsaturated polyester resin, 1 part of lignocellulose of 1250 mesh, 3 parts of hydroxymethyl cellulose of 1000 mesh, 0.5 part of aluminum stearate of 1500 mesh, 4.5 parts of 1000 mesh barium stearate, 0.1 part of 2-hydroxy-4-methoxybenzophenone, 0.4 part of 2-(2'-hydroxy-5'-methylphenyl)benzotriazole, 2000 20 parts of silica, 10 parts of heavy calcium carbonate of 4000 mesh, 10 parts of aluminum hydroxide of 5000 mesh, 15 parts of Shuangfei powder of 2500 mesh, 0.02 part of ultramarine blue and 5 parts of titanium dioxide.

Embodiment 2

[0129] Embodiment 2 (by weight parts)

[0130] The stone material seamless adhesive is calculated in parts by weight, consisting of 100 parts of pre-accelerated unsaturated polyester resin, 1 part of lignocellulose of 1000 mesh, 2 parts of hydroxyethyl cellulose of 1500 mesh, 4 parts of aluminum stearate of 1000 mesh, 2 parts of 3000 mesh lithium stearate, 0.3 part of p-tert-butylphenyl salicylate, 0.5 part of 2-(2'-hydroxy-5'-methylphenyl) benzotriazole, 1250 mesh of silicon dioxide 20 parts, 30 parts of heavy calcium carbonate of 1500 mesh, 50 parts of aluminum hydroxide of 1000 mesh, 5 parts of talc powder of 1250 mesh, 80 parts of Shuangfei powder of 5000 mesh, and 1 part of chromium oxide green.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com