A kind of red fluorescent material for white light LED and preparation method thereof

A technology for red fluorescent and luminescent materials, applied in luminescent materials, chemical instruments and methods, sustainable manufacturing/processing, etc., can solve the problems of complex preparation methods, poor color reproduction, lack of red light components, etc., and achieve good repeatability , The effect of pure chromaticity and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Preparation of Ba 2.7 Eu 0.3 MgSb 2 o 9 , according to the chemical formula Ba 2.7 Eu 0.3 MgSb 2 o 9 The stoichiometric ratio of each element in the formula is weighed separately from barium carbonate BaCO 3 : 1.3321 g, europium oxide Eu 2 o 3 : 0.1319 g, magnesium oxide MgO: 0.1008 g, antimony pentoxide Sb 2 o 5 : 0.8088g, ground in an agate mortar and mixed evenly, then pre-calcined in a muffle furnace at 850°C for 3 hours in an air atmosphere, cooled to room temperature naturally, and took out the sample; fully mixed and ground evenly, and placed in the muffle furnace again In the furnace, in the air atmosphere, calcined at 1400 ° C for 2 hours, cooled to room temperature naturally, and after taking it out, it was fully ground to obtain a powdery luminescent material.

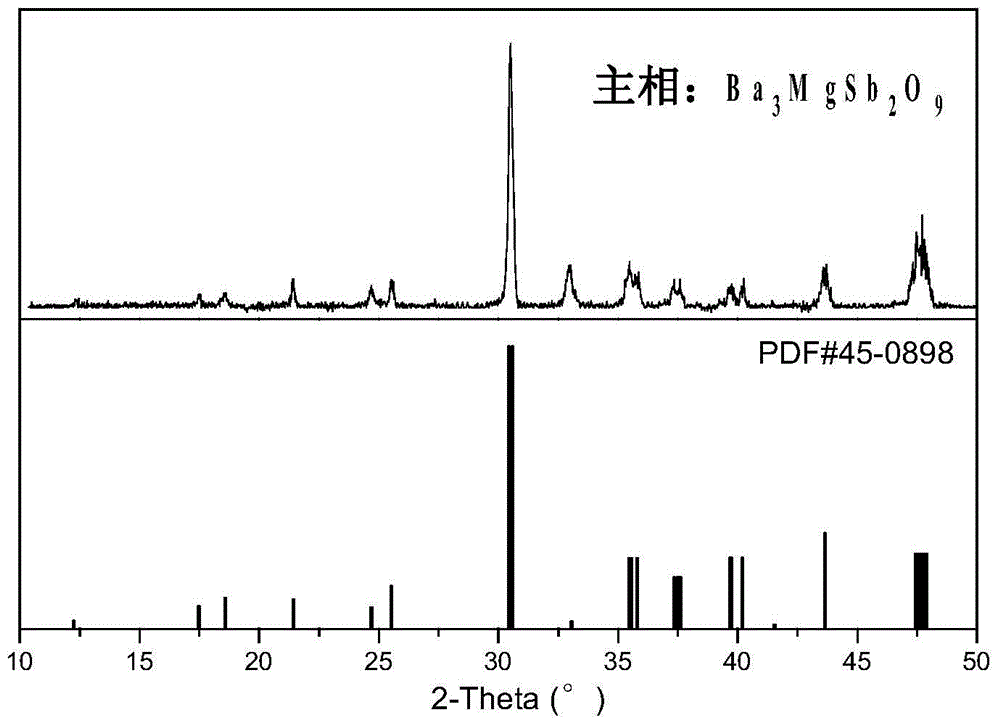

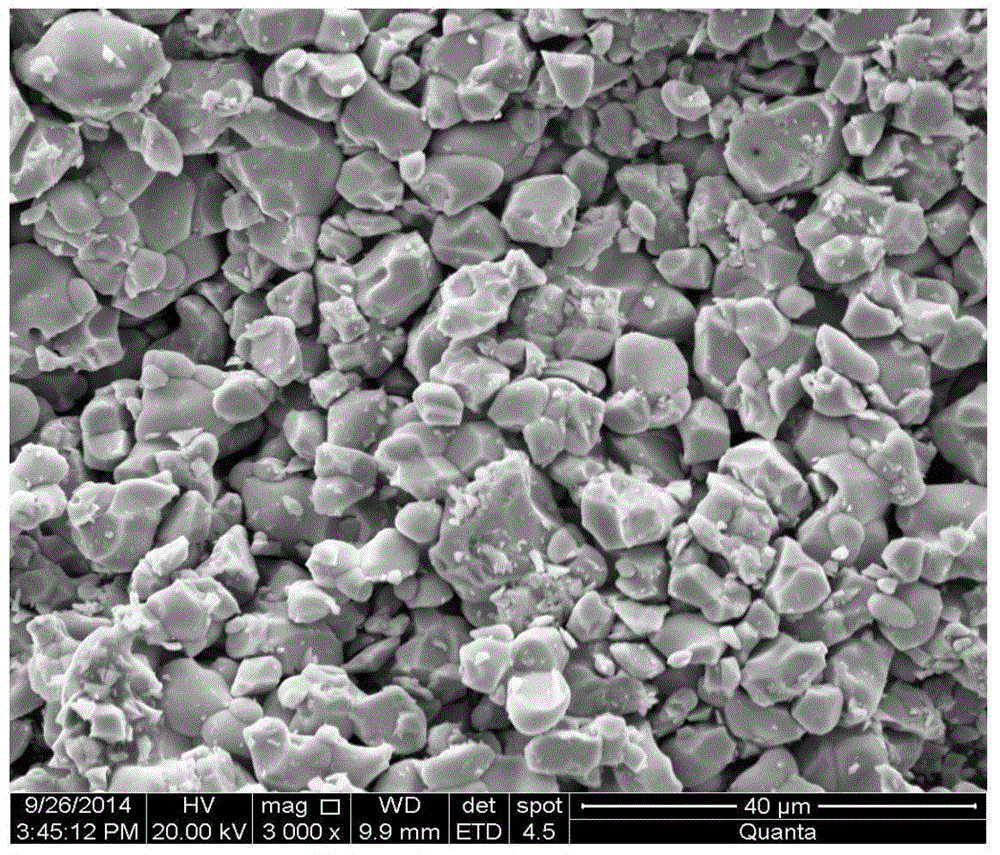

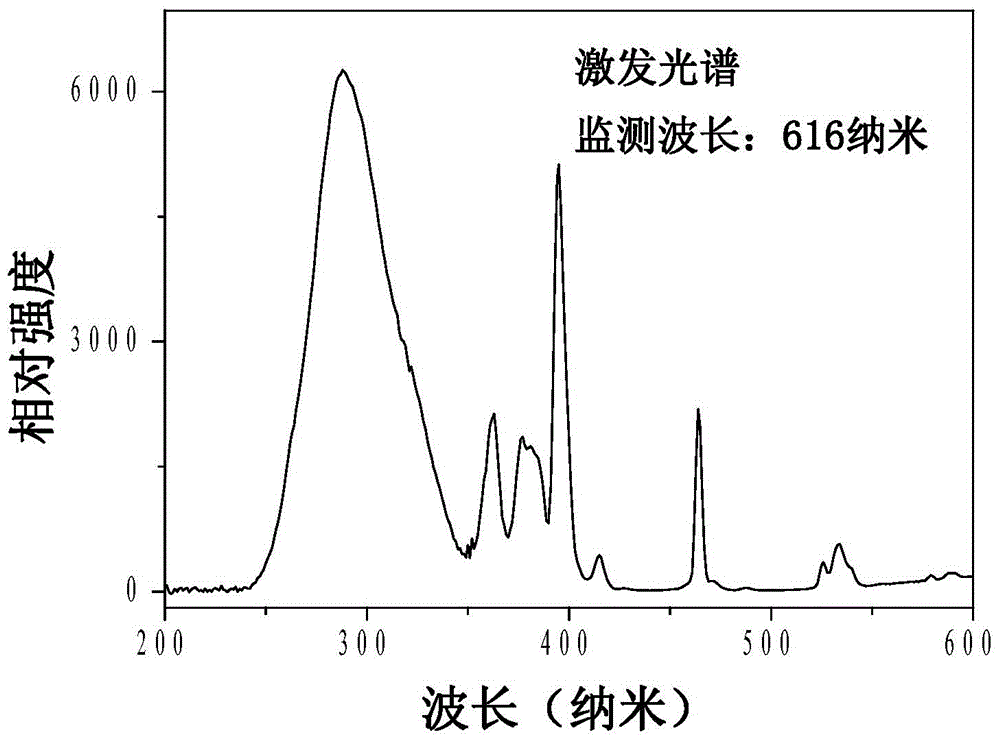

[0035] See attached figure 1 , which is the X-ray powder diffraction pattern of the sample prepared by the technical scheme of this embodiment. The test results show that no other miscella...

Embodiment 2

[0041] Preparation of Ba 2.64 Eu 0.36 MgSb 2 o 9 , according to the chemical formula Ba 2.64 Eu 0.36 MgSb 2 o 9 The stoichiometric ratio of each element in the element, respectively weighed barium nitrate Ba (NO 3 ) 2 : 1.7248 g, europium oxide Eu 2 o 3 : 0.1584 g, magnesium carbonate basic 4MgCO 3 ·Mg(OH) 2 ·5H 2 O: 0.2429 g, antimony pentoxide Sb 2 o 5 : 0.8088 g, ground and mixed in an agate mortar, pre-calcined in an air atmosphere at 900 ° C for 2 hours in a muffle furnace, cooled to room temperature naturally, and took out the sample; fully mixed and ground evenly, placed in the muffle furnace again In the furnace, in the air atmosphere, calcined at 1500 ° C for 1 hour, cooled to room temperature naturally, and after taking it out, it was fully ground to obtain a powdery luminescent material.

[0042] The sample prepared in this example is similar to Example 1 in its main structural appearance, excitation spectrum, emission spectrum and luminescence decay ...

Embodiment 3

[0044] Preparation of Ba 2.55 Eu 0.45 MgSb 2 o 9 , according to the chemical formula Ba 2.55 Eu 0.45 MgSb 2 o 9 The stoichiometric ratio of each element in the formula is weighed separately for barium oxide BaO: 0.9775 grams, europium oxide Eu 2 o 3 : 0.1979 g, magnesium oxide MgO: 0.1008 g, antimony pentoxide Sb 2 o 5 : 0.8088g, ground in an agate mortar and mixed evenly, pre-calcined in a muffle furnace at 500°C for 16 hours in an air atmosphere, cooled naturally to room temperature, and took out the sample; fully mixed and ground evenly, and placed in the muffle furnace again In the furnace, in the air atmosphere, calcined at 900°C for 12 hours, cooled naturally to room temperature, and after taking it out, it was fully ground to obtain a powdery luminescent material.

[0045] The sample prepared in this example is similar to Example 1 in its main structural appearance, excitation spectrum, emission spectrum and luminescence decay curve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com