Inverted solar cell structure adopting surface plasmon effect and manufacturing method thereof

A surface plasmon, solar cell technology, applied in the manufacturing/processing of organic semiconductor devices, circuits, photovoltaic power generation, etc. Separation and transmission, improving photoelectric conversion efficiency, avoiding the effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

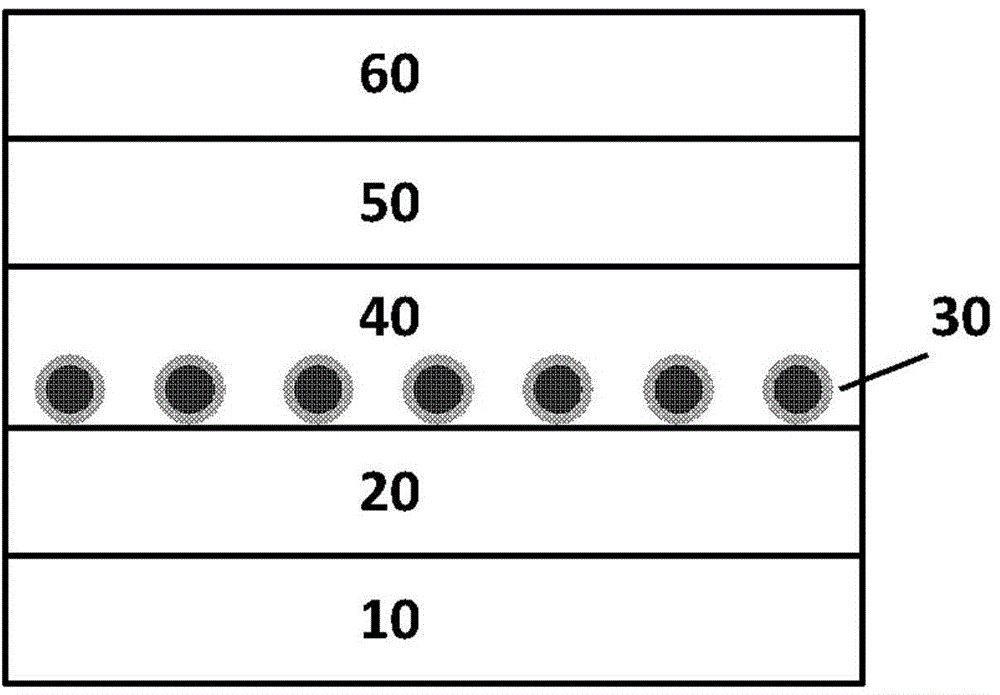

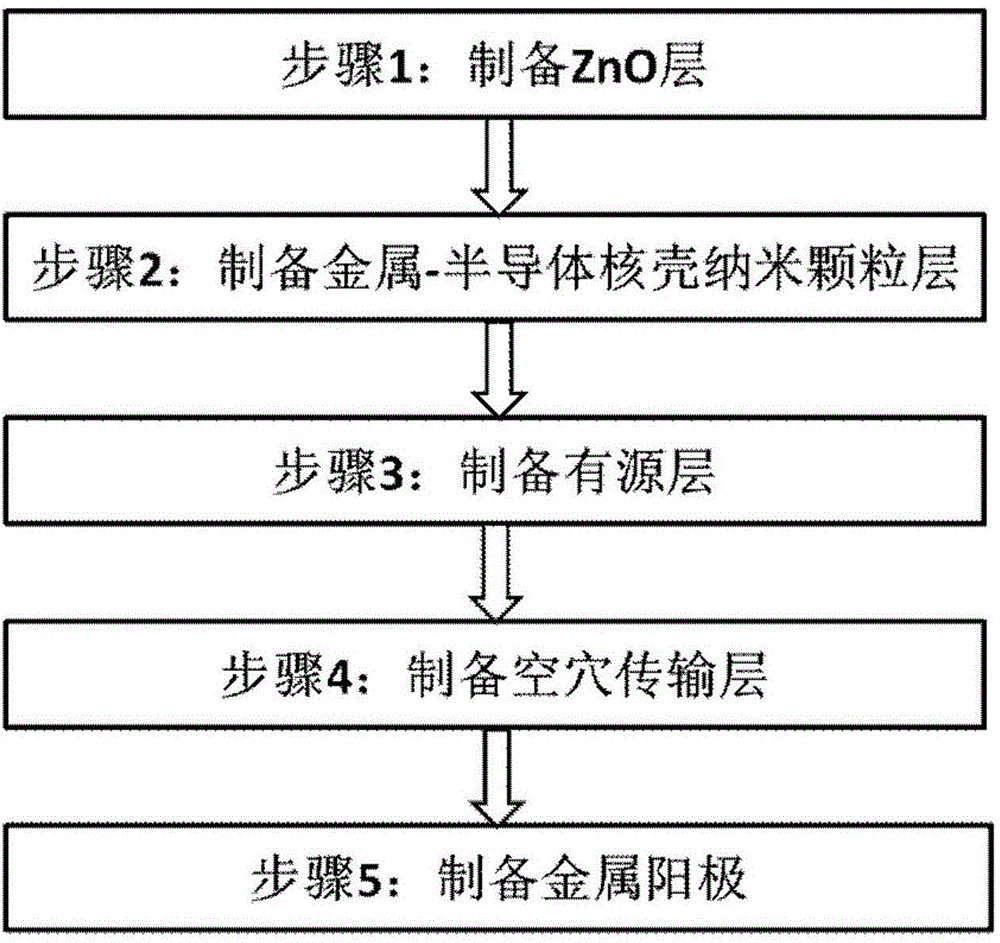

[0032] see figure 2 , the present invention also provides a method for preparing an inverted solar cell using the surface plasmon effect, comprising the following steps:

[0033] Step 1: Spin-coat a layer of ZnO precursor solution on the cathode transparent conductive substrate 10, and sinter at a predetermined temperature for a predetermined time to form a dense ZnO electron transport layer 20. The thickness of the ZnO electron transport layer 20 is 20 -50nm, the precursor solution is a mixed solution of zinc acetate, ethylene glycol methyl ether and ethanolamine, the precursor solution is colorless and transparent, the spin coating rate is 2000-5000rpm, the sintering temperature is 130°C-300°C, and the sintering time is 10min- 2h, obtain the dense ZnO thin film of high light transmittance, adopt this kind of method to prepare ZnO thin film, the step is simple, the obtained ZnO thin film is compact, good stability;

[0034] Step 2: Spin-coat a layer of metal-semiconductor c...

Embodiment

[0039] (1) First prepare Ag-TiO by two-step method 2 core-shell nanoparticles

[0040] Synthesize Ag nanoparticles first:

[0041] Mix 0.288g polyvinylpyrrolidone with 30mL ethylene glycol, stir magnetically until the polyvinylpyrrolidone is completely dissolved, and record it as solution A. Mix 0.288g of silver nitrate with 30mL of ethylene glycol, stir magnetically until the silver nitrate is completely dissolved, and record it as solution B. Mix solution A and solution B into a 100mL flask, slowly raise the temperature to 120°C under magnetic stirring, and react at 120°C for 10min. Then the product was cooled to room temperature, and washed by centrifugation with acetone, ethanol and deionized water to obtain Ag nanoparticles. The Ag nanoparticles were dispersed into deionized water, and the concentration was controlled at 1 mg / mL.

[0042] Ag nanoparticles coated TiO 2 :

[0043] Add 0.05mL tetrabutyl titanate into 10mL ethylene glycol, stir for 10h, and record it as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Shell thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com