Method for manufacturing artificial blood vessels with double-layered structures and application of artificial blood vessels

A technology of artificial blood vessels and double-layer structure, which is applied in the direction of human tubular structure devices, blood vessels, veterinary instruments, etc., can solve the problems of hindering the regeneration of pseudo-natural blood vessels, the inability to regenerate smooth muscle layers, and the lack of orientation of smooth muscle layers. Blood compatibility, safe and non-toxic materials, and the effect of avoiding aneurysm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

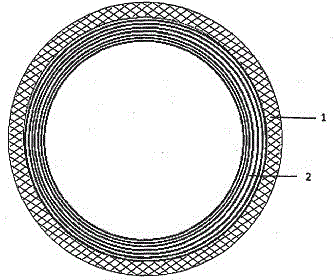

[0011] Example 1: Preparation of PGA oriented microfiber inner layer and PLA random nanofiber outer double-layer structure artificial blood vessel

[0012] Preparation of the inner layer spinning solution: Weigh 1.0 g of PGA with a number average molecular weight of 100,000, add it to 10 ml of hexafluoroisopropanol, stir until it dissolves evenly, and prepare a PGA solution with a concentration fraction of 10% (m / v).

[0013] Preparation of the outer layer spinning solution: Weigh 2.0 g of PLA with a number average molecular weight of 300,000, add it to 10 ml of chloroform, stir until it dissolves evenly, and prepare a solution with a concentration fraction of 20% (m / v) PLA.

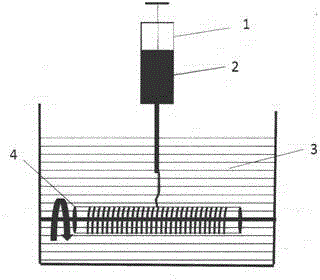

[0014] Preparation of the inner layer of the artificial blood vessel: the wet spinning of the inner layer was carried out in a fume hood at room temperature. Connect a cylindrical receiving rod with a diameter of 1.0 mm to a rotating motor. The PGA spinning solution was sucked into the syringe, and the ...

Embodiment 2

[0016] Example 2: Preparation of double-layer structure artificial blood vessel with PLGA oriented microfiber inner layer and PLCL random nanofiber outer layer

[0017] Preparation of the inner layer spinning solution: Weigh 1.2 grams of PLGA (LA / GA, 75:25), add it to 10 ml of chloroform, stir until it dissolves evenly, and prepare a PLGA solution with a concentration fraction of 12% (m / v).

[0018]Preparation of the outer layer spinning solution: Weigh 0.8 g of PLCL (50:50), add it into 10 ml of dichloromethane, stir until it dissolves evenly, and prepare a PLCL solution with a concentration fraction of 8% (m / v).

[0019] Preparation of the inner layer of the artificial blood vessel: the wet spinning of the inner layer was carried out in a fume hood at room temperature. Connect a cylindrical receiving rod with a diameter of 2.0mm to the rotating motor. The 12% PLGA spinning solution was sucked into the syringe, and the needle of the syringe was inserted into the edible oil i...

Embodiment 3

[0021] Example 3: Preparation of artificial blood vessel with double-layer structure of silk fibroin-oriented microfiber inner layer and PCL random nanofiber outer layer

[0022] Preparation of inner layer spinning solution: Weigh 2 grams of silk fibroin freeze-dried product, add to 10mL hexafluoroisopropanol solvent, stir until dissolved evenly, centrifuge at 10000rpm to discard the precipitate, and collect the concentration fraction to be 20% (m / v ) of SF solution.

[0023] Preparation of the outer layer spinning solution: Weigh 1.2 g of PCL and add it to 12 ml of chloroform / methanol (5:1), stir until it dissolves evenly, and obtain a PCL solution with a concentration fraction of 10% (m / v).

[0024] Preparation of the inner layer of the artificial blood vessel: the wet spinning of the inner layer was carried out in a fume hood at room temperature. Connect the 4.0mm diameter cylindrical receiving rod to the rotating motor. The silk fibroin spinning solution is sucked into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com