Preparation method and application of composite bone cement precursor, strontium borate bioglass/polymethyl methacrylate composite bone cement

A technology of polymethyl methacrylate and methyl methacrylate, applied in the field of biomedical repair materials, can solve the problems of lack of biological activity and osseointegration, unsatisfactory histocompatibility, and easy damage to host tissue, etc. Good injectability, excellent injectability, the effect of reducing mechanical shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0092] A preparation method of strontium borate bioglass / polymethyl methacrylate composite bone cement, comprising the steps of:

[0093] (1) Preparation of solid phase powder:

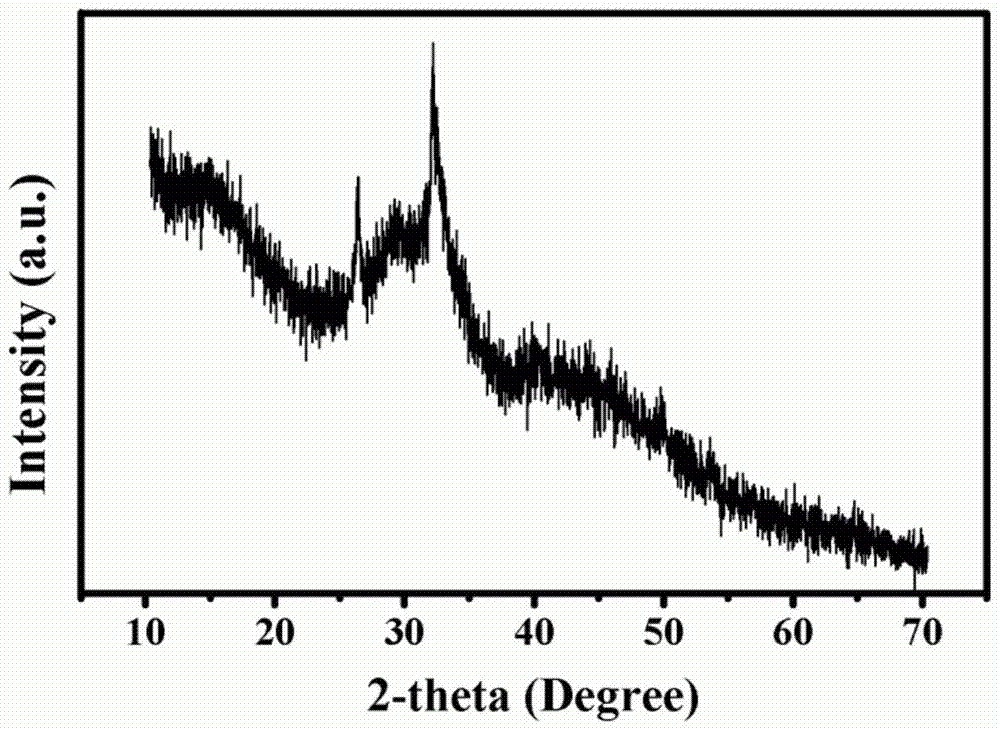

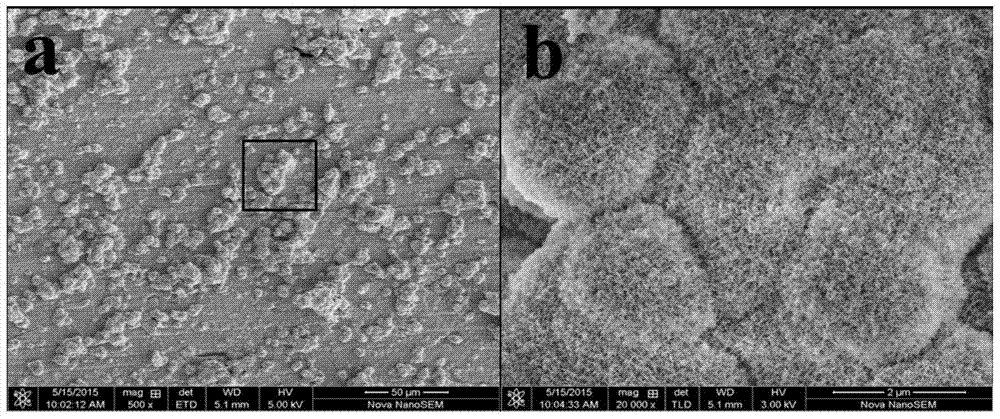

[0094] Preparation of strontium borate bioglass:

[0095] Weigh strontium borate bioglass 14SrO·2CaO·8MgO·54B according to molar ratio 2 o 3 ·2P 2 o 5 0SiO2 2 6Na 2 O·6K 2 After the raw materials of each component of O are mixed evenly, the original ingredients are placed in a platinum crucible and placed in a silicon-molybdenum furnace at 1100-1150 ° C, melted for 4 hours, and after taking it out, pour the obtained clear glass liquid into a preheated Get glass blocks on the steel plate. The obtained glass block is successively crushed, ball milled and sieved by crushing equipment, and the strontium borate bioglass with a particle diameter of 20-40 μm is selected for use;

[0096] Choose the polymethyl methacrylate (PMMA) powder that particle diameter is 20-40 μ m, the above-mentioned made st...

Embodiment 2

[0117] A preparation method of strontium borate bioglass / polymethyl methacrylate composite bone cement, comprising the steps of:

[0118] (1) Preparation of solid phase powder:

[0119] Preparation of strontium borate bioglass:

[0120] Weigh strontium borate bioglass 8SrO·22CaO·36B according to molar ratio 2 o 3 10P 2 o 5 18SiO2 2 · 8Na 2 After the raw materials of each component of O are mixed evenly, the original ingredients are placed in a platinum crucible and placed in a silicon-molybdenum furnace at 1100-1150 ° C, melted for 4 hours, and after taking it out, pour the obtained clear glass liquid into a preheated Get glass blocks on the steel plate. The obtained glass block is further crushed and classified by crushing equipment, and the strontium borate bioglass with a particle diameter of 20-40 μm is selected for use;

[0121] Select polymethyl methacrylate (PMMA) powder with a particle size of 40-60 μm, and mix the above-mentioned strontium borate bioglass with...

Embodiment 3

[0130] A preparation method of strontium borate bioglass / polymethyl methacrylate composite bone cement, comprising the steps of:

[0131] (1) Preparation of solid phase powder:

[0132] Preparation of strontium borate bioglass:

[0133] Weigh strontium borate bioglass 2SrO·14CaO·8MgO·18B according to molar ratio 2 o 3 ·4P 2 o 5 ·36SiO2 2 14K 2 After mixing the raw materials of each component of O.4CuO evenly, put the original ingredients in a platinum crucible and place it in a silicon-molybdenum furnace at 1100-1150°C, melt it for 4 hours, take it out, and pour the obtained clear glass liquid into the prepared Get the glass block on the hot steel plate. The obtained glass block is successively crushed, ball milled and sieved by crushing equipment, and the strontium borate bioglass with a particle diameter of 20-40 μm is selected for use;

[0134] Choose the polymethyl methacrylate (PMMA) powder that particle diameter is 60-80 μ m, the above-mentioned made strontium bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com