Dendritic high-density solid amine fiber material and preparation method therefor

A high-density, amine fiber technology, which is applied in the field of dendritic high-density solid amine fiber materials and its preparation, can solve the problems of insufficient adsorption capacity, and achieve the effects of increased adsorption capacity, high amine group density, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1. Preparation

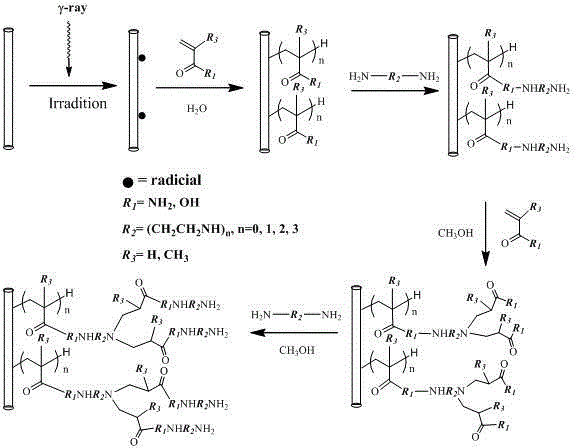

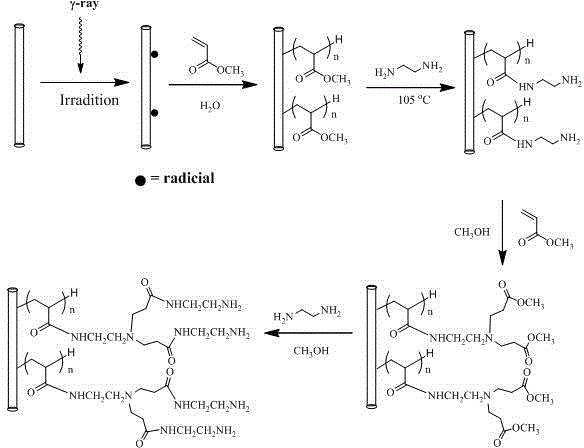

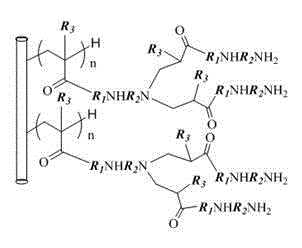

[0045] The preparation reaction formula is attached figure 2 As shown, the specific steps are as follows:

[0046] (1) The polypropylene fiber was immersed in 15 wt% NaOH aqueous solution, soaked for 24 hours, the solution was poured out, and the fiber was washed with water several times until the washing liquid became neutral, and dried in a vacuum oven at 70 ℃ to constant weight.

[0047] (2) Weigh 10 g of the polypropylene fiber obtained in step (1), place it in a conical flask with a stopper, and seal it with a polytetrafluoroethylene film. Use cobalt 60 as the irradiation source, and control the irradiation measurement to 40 KGy, and the irradiation time to 50 h. Mix methyl acrylate and methanol at a volume percentage of 40:60 to make 160 mL of a uniform mixed solution, add 4 g of pre-irradiated polypropylene fiber at a bath ratio of 1:40 (weight: volume) at 60 ℃ Reaction for 3 h. After the grafting reaction is over, the fiber is taken out, and the gr...

Embodiment 2

[0054] 1. Preparation

[0055] (1) The polypropylene fiber was immersed in 15 wt% NaOH aqueous solution, soaked for 24 hours, the solution was poured out, and the fiber was washed with water several times until the washing liquid became neutral, and dried in a vacuum oven at 70 ℃ to constant weight.

[0056] (2) Weigh 10 g of the polypropylene fiber obtained in step (1), place it in a conical flask with a stopper, and seal it with a polytetrafluoroethylene film. Use cobalt 60 as the irradiation source, and control the irradiation measurement to 40 KGy, and the irradiation time to 50 h. Add 4 g of pre-irradiated polypropylene fiber to 25 / 75 (v / v)% methyl acrylate / water mixture at a bath ratio of 1:40 (weight: volume), and react at 80 ℃ 1 h. After the grafting reaction is over, the fiber is taken out, and the grafted fiber is washed repeatedly with N,N-dimethylformamide to remove homopolymer and unreacted grafted monomer, and finally washed with ethanol, and dried in vacuum to a co...

Embodiment 3

[0063] 1. Preparation

[0064] (1) Dip the viscose fiber into 8wt% NaOH aqueous solution, soak for 24 hours, pour off the solution, wash the fiber with water several times until the washing liquid is neutral, and dry it in a vacuum oven at 70 ℃ to constant weight.

[0065] (2) Weigh 10 g of the polypropylene fiber obtained in step (1), place it in a conical flask with a stopper, and seal it with a polytetrafluoroethylene film. Use cobalt 60 as the irradiation source, and control the irradiation measurement to 40 KGy, and the irradiation time to 50 h. Prepare a uniform mixture of acrylamide monomer and water at a mass-to-volume ratio of 15 / 85. Add 4.0 g of pre-irradiated viscose fiber at a bath ratio of 1:30 (weight: volume) at 70 ℃ Reaction for 4 h. After the grafting reaction is over, the fiber is taken out, and the grafted fiber is washed repeatedly with hot water to remove homopolymer and unreacted grafting monomer, and finally washed with ethanol, dried in vacuum to constant ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com