Precious metal/zinc indium sulfide/titanium dioxide nano heterostructure photocatalyst and preparation method thereof

A nano-heterostructure and photocatalyst technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, nanotechnology, etc., can solve problems such as limiting quantum yield, wide band gap, and fast recombination of photogenerated carriers. Achieve the effect of improving ultraviolet light absorption efficiency, promoting separation and enhancing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

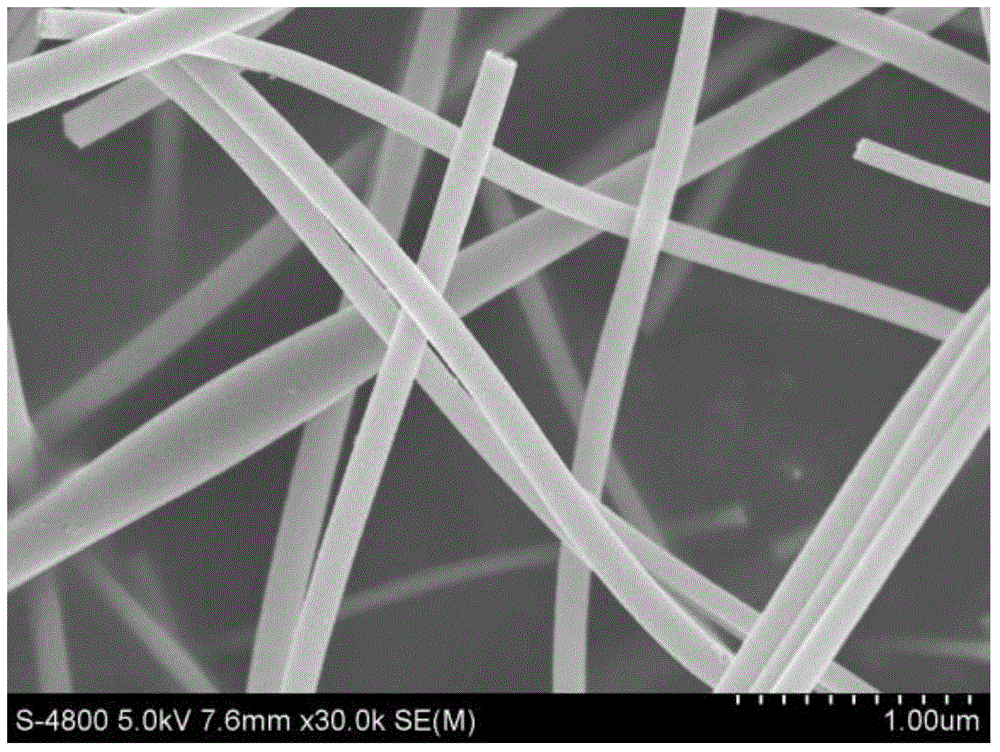

[0028] 2ml of glacial acetic acid and 2ml of butyl titanate were added to 4.5ml of absolute ethanol, and then 0.4g of polymer polyvinylpyrrolidone was dissolved in the above solution to prepare a butyl titanate / polyvinylpyrrolidone precursor solution. Next, put the precursor solution into a medical syringe with a nozzle with a diameter of 0.4mm, keep the distance between the nozzle and the grounded receiving plate at 12cm, put the copper electrode into the solution and apply a high voltage of 10KV to perform electrospinning, Preparation of butyl titanate / polyvinylpyrrolidone composite nanofibers. Finally, butyl titanate / polyvinylpyrrolidone composite nanofibers were calcined in a muffle furnace at a rate of 2 °C / min to 500 °C for 1 hour to obtain TiO 2 Nanofibers. Prepared TiO 2 Scanning electron micrographs of nanofibers as figure 1 shown. It can be clearly seen from the figure that the prepared TiO 2 The nanofibers have a diameter of 200-300 nm and a length of 10-20 μm....

Embodiment 2

[0032] 1.5 ml of glacial acetic acid and 1.5 ml of butyl titanate were added to 4 ml of absolute ethanol, and then 0.4 g of polymer polyvinyl pyrrolidone was dissolved in the above solution to prepare a butyl titanate / polyvinyl pyrrolidone precursor solution. Next, put the precursor solution into a medical syringe with a nozzle with a diameter of 0.4mm, keep the distance between the nozzle and the grounded receiving plate at 10cm, put the copper electrode into the solution and apply a high voltage of 11KV to perform electrospinning, Preparation of butyl titanate / polyvinylpyrrolidone composite nanofibers. Finally, butyl titanate / polyvinylpyrrolidone composite nanofibers were calcined in a muffle furnace at a rate of 3 °C / min to 500 °C for 0.5 hours to obtain TiO 2 Nanofibers.

[0033] Add 0.13 mmol of zinc acetate dihydrate, 0.26 mmol of indium nitrate hexahydrate, 0.95 mmol of cysteine and 0.0525 mmol of sodium hydroxide into 20 ml of deionized water, and stir magnetically ...

Embodiment 3

[0036] 2ml of glacial acetic acid and 2ml of butyl titanate were added to 4ml of absolute ethanol, and then 0.4g of polymer polyvinylpyrrolidone was dissolved in the above solution to prepare a butyl titanate / polyvinylpyrrolidone precursor solution. Next, put the precursor solution into a medical syringe with a nozzle with a diameter of 0.4mm, keep the distance between the nozzle and the grounded receiving plate at 12cm, put the copper electrode into the solution and apply a high voltage of 10KV to perform electrospinning, Preparation of butyl titanate / polyvinylpyrrolidone composite nanofibers. Finally, butyl titanate / polyvinylpyrrolidone composite nanofibers were calcined in a muffle furnace at a rate of 3 °C / min to 500 °C for 2 hours to obtain TiO 2 Nanofibers.

[0037] Add 0.125 mmol of zinc acetate dihydrate, 0.25 mmol of indium nitrate hexahydrate, 0.8 mmol of cysteine and 0.0625 mmol of sodium hydroxide into 20 ml of deionized water, and stir magnetically for 30 min. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com