Shielding welding wire and production method thereof

A gas shielded welding and wire drawing technology, used in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problem of not being able to reduce spatter, and achieve the effects of not easy deformation, welding wire quality assurance, and oxidation prevention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

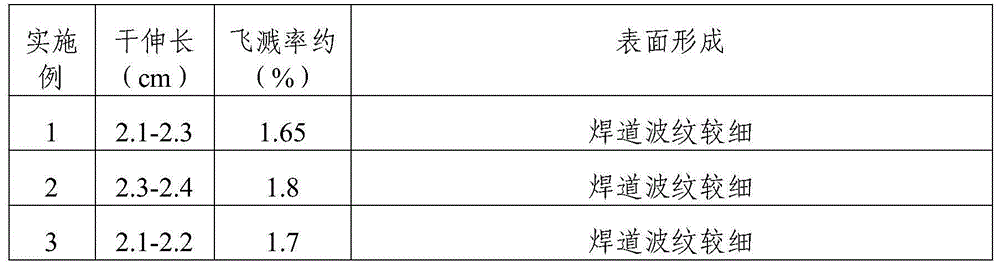

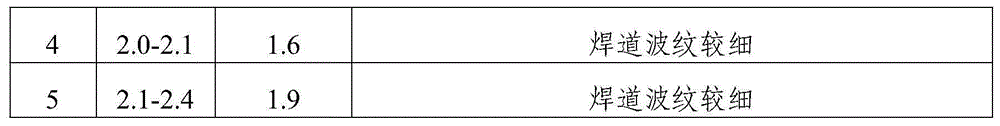

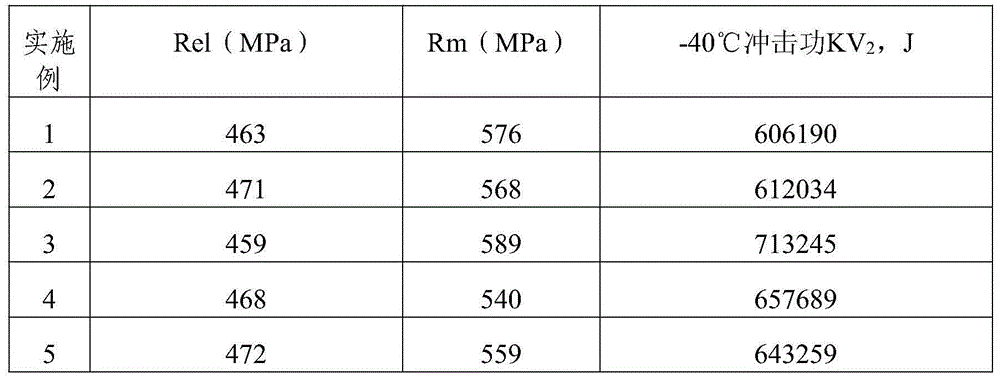

Examples

Embodiment 1

[0029] A gas shielded welding wire, the mass percentage of the chemical composition of its raw materials is: C: 0.01%, Si: 1.3%, Mn: 1.1%, Ti: 2.1%, S: 0.009%, Al: 0.23%, P≤0.004 %, B: 0.003%, V: 0.001%, and the balance is iron and unnecessary impurities.

[0030] The chemical composition of the raw materials also includes Cr, and its mass percentage is 0.0002%.

[0031] The chemical composition of the raw materials also includes Cu, and its mass percentage is 0.02%.

[0032]When it is applied to welding, the protective gas used is a mixed gas of carbon dioxide gas and argon gas, wherein the volume percentage of carbon dioxide gas in the mixed gas is 91.3%.

[0033] The above-mentioned preparation method of gas-shielded welding wire includes the steps of smelting, rolling, wire drawing, copper plating, and wire coiling. During the smelting process, a vacuum furnace is used for vacuum smelting treatment, and the vacuum degree is 0.3 MPa.

[0034] The rolling is carried out at...

Embodiment 2

[0040] A gas shielded welding wire, the mass percentage of the chemical composition of its raw materials is: C: 0.02%, Si: 1.2%, Mn: 1.3%, Ti: 1.9%, S: 0.01%, Al: 0.25%, P≤0.009 %, B: 0.006%, V: 0.0009%, and the balance is iron and unnecessary impurities.

[0041] The chemical composition of the raw materials also includes Cr, and its mass percentage is 0.0003%.

[0042] The chemical composition of the raw materials also includes Cu, and its mass percentage is 0.03%.

[0043] When it is applied to welding, the protective gas used is a mixed gas of carbon dioxide gas and argon gas, wherein the volume percentage of carbon dioxide gas in the mixed gas is 98.17%.

[0044] The above gas-shielded welding wire preparation method includes the steps of smelting, rolling, wire drawing, copper plating, and wire coiling. During the smelting process, a vacuum furnace is used for vacuum smelting treatment, and the vacuum degree is 0.8 MPa.

[0045] The rolling is carried out at a temperat...

Embodiment 3

[0051] A gas shielded welding wire, the mass percent of the chemical composition of its raw materials is: C: 0.025%, Si: 1.2%, Mn: 1.7%, Ti: 1.5%, S: 0.011%, Al: 0.26%, P≤0.008 %, B: 0.006%, V: 0.0008%, and the balance is iron and unnecessary impurities.

[0052] The chemical composition of the raw materials also includes Cr, and its mass percentage is 0.0001%.

[0053] The chemical composition of the raw materials also includes Cu, and its mass percentage is 0.01%.

[0054] When it is applied to welding, the protective gas used is a mixed gas of carbon dioxide gas and argon gas, wherein the volume percentage of carbon dioxide gas in the mixed gas is 95.73%.

[0055] The above gas-shielded welding wire preparation method includes the steps of smelting, rolling, wire drawing, copper plating, and wire coiling. During the smelting process, a vacuum furnace is used for vacuum smelting treatment, and the vacuum degree is 0.5 MPa.

[0056] The rolling is carried out at a temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com