White poplar wood frame strip and manufacturing method thereof

A manufacturing method and technology of poplar, which are applied in the direction of manufacturing tools, wood layered products, and the joining of wooden veneers, can solve the problems of unstable structural properties, limited application fields, and difficulty in grinding and sanding, and achieve improved physical properties. Mechanical properties, application durability, density-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

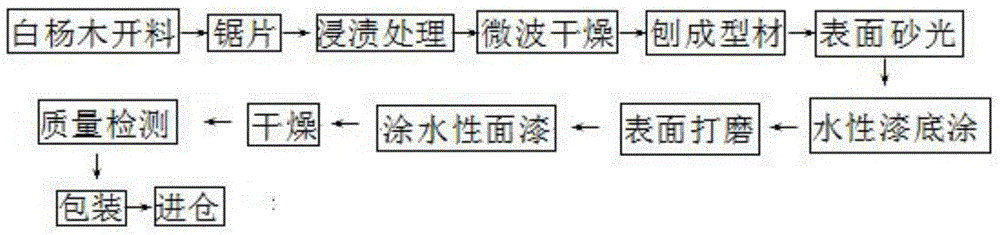

[0069] A method for manufacturing poplar wood frame strips, the method comprising cutting poplar wood, sawing blades, dipping treatment, microwave drying, planing profiles, surface sanding, water-based paint primer, surface grinding, water-based topcoat, and drying , quality inspection and packaging steps:

[0070] 1. Firstly, the aspen wood is cut into saw blades, and then soaked at room temperature. The formula of the dipping solution is as follows: tributyltin naphthenate 2-3.5; nonylphenol polyoxyethylene ether 18.5-21.5; ammonium salt dosage 6.8-7.5; Nitrilotriacetic acid (NTA) 8.3~8.8; polyvinyl acetate 5~6.5; boric acid 3~3.7; ketone compounds 1.2~2.5; ethanol 8~9; polyethylene glycol (400) 0~2; water 35 ~38.

[0071] Specifically, it can be prepared according to Table 1

[0072]

[0073] The ammonium salt can be selected from one of tetradecyltrimethylammonium chloride (TTAC) or triethylenetriamine; the ketone compound can be selected from one of acetone, butanone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com