Nano-composite environment-friendly coal saving agent

A nano-composite and coal-saving agent technology, applied in the field of coal-fired additives, can solve the problems of coal-fired boilers not having a combustion-supporting effect, the desulfurization effect is not obvious, and the thermal efficiency of coal-fired pathways is low, so that it is easy to disperse coal and reduce costs. Effect of low and air permeability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

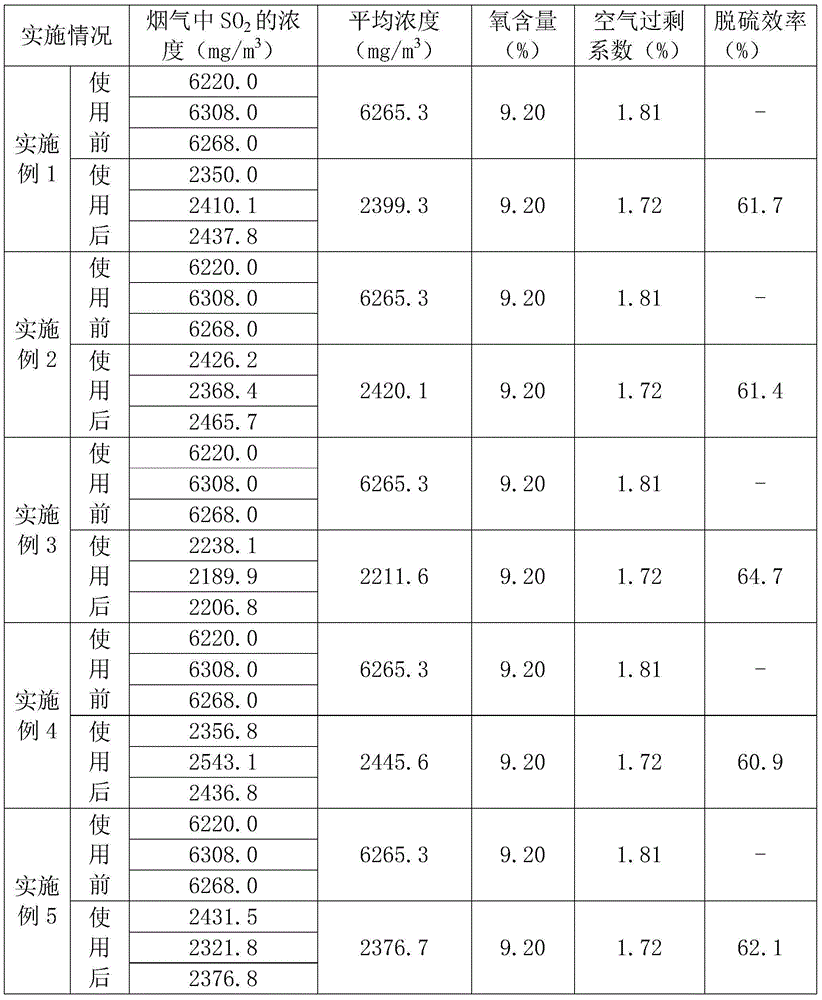

Examples

Embodiment 1

[0034] A nano-composite environmental-friendly coal-saving agent, the mass parts of the coal-saving agent are composed as follows: 5 parts of composite catalyst, 6 parts of combustion enhancer, 40 parts of penetrating agent, 10 parts of leavening agent, 5 parts of cleaning agent, 2 parts of sulfur-fixing agent share;

[0035] Described composite catalyst selects the mixture of ferric chloride, ferric oxide, potassium carbonate, alumina, manganese dioxide and magnesium chloride, and its mass ratio is 1:1:1.2:2:1:1;

[0036] Described combustion aid selects the mixture of potassium permanganate and potassium nitrate for use, and its mass ratio is 2:1;

[0037] The osmotic agent is selected from the mixture of water, methanol, ethanol and Tween, and its volume ratio is 2:1:1:0.8;

[0038] Described leavening agent selects industrial salt for use;

[0039] The cleaning agent is selected from the mixture of polyoxyethylene and fatty alcohol polyoxyethylene ether, and its mass rat...

Embodiment 2

[0043] A nano-composite environmental-friendly coal-saving agent, the mass parts of the coal-saving agent are composed as follows: 8 parts of composite catalyst, 8 parts of combustion improver, 42 parts of penetrating agent, 12 parts of leavening agent, 6 parts of cleaning agent, 3 parts of sulfur-fixing agent share;

[0044] The composite catalyst is selected from ferric chloride, ferric oxide, potassium carbonate, alumina, manganese dioxide, magnesium chloride and nano-scale titanium dioxide powder mixture, and its mass ratio is 1:1:1.4:2.2:1.2:1:0.02;

[0045] Described combustion aid selects the mixture of potassium permanganate and potassium nitrate for use, and its mass ratio is 2.2:1;

[0046] The osmotic agent is selected from the mixture of water, methanol, ethanol and Tween, and its volume ratio is 2.2:1:1:0.8;

[0047] Described leavening agent selects industrial salt for use;

[0048] The cleaning agent is selected from the mixture of polyoxyethylene and fatty al...

Embodiment 3

[0052] A nano-composite environmental protection coal-saving agent, the composition of the coal-saving agent is as follows: 10 parts of composite catalyst, 12 parts of combustion enhancer, 45 parts of penetrant, 15 parts of leavening agent, 8 parts of cleaning agent, 5 parts of sulfur-fixing agent share;

[0053] The composite catalyst is selected from the mixture of ferric chloride, ferric oxide, potassium carbonate, alumina, manganese dioxide, magnesium chloride and nano-scale titanium dioxide powder, and its mass ratio is 1:1:1.5:2.5:1.5:1:0.05 ;

[0054] Described combustion aid selects the mixture of potassium permanganate and potassium nitrate for use, and its mass ratio is 2.5:1;

[0055] The osmotic agent is selected from the mixture of water, methanol, ethanol and Tween, and its volume ratio is 2.5:1:1:0.8;

[0056] Described leavening agent selects industrial salt for use;

[0057] The cleaning agent is a mixture of polyoxyethylene and fatty alcohol polyoxyethylen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com