Graphitized carbon material and preparation method thereof, and supercapacitor

A technology of graphitized carbon and degree of graphitization, applied in the direction of hybrid capacitor electrodes, etc., can solve the problems of low energy density of commercial supercapacitors, can not significantly improve the conductivity of activated carbon, etc., and achieve the effect of high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The present invention provides a kind of preparation method of graphitized carbon material described in above-mentioned technical scheme, comprises the following steps:

[0045] a), the carbon source is mixed with the metal catalyst to obtain a carbon source adsorbed with the metal catalyst;

[0046] The metal catalyst includes one or more of nickel salt, iron salt, molybdenum salt, cobalt salt and tungsten salt;

[0047] The mass ratio of the carbon source to the metal catalyst is 1: (0.001-2);

[0048] b), the carbon source adsorbed with the metal catalyst is mixed with an activator to obtain a precursor;

[0049] The activator includes one or more of water vapor, potassium hydroxide, phosphoric acid, zinc chloride, sodium hydroxide;

[0050] The mass ratio of the activator to the carbon source in step a) is (0.5-10):1;

[0051] c) The precursor is heated and carbonized in an inert gas atmosphere to obtain a graphitized carbon material.

[0052] In the preparation...

Embodiment 1

[0090] Get 100g phenolic resin (4169, Taiwan Changchun), it is immersed in the aqueous solution that contains 50g nickel sulfate in 200ml, dry, obtain the phenolic resin that adsorbs metal ion catalyst; solution, dried and pulverized to obtain a precursor.

[0091] Put the precursor in a tube furnace, in a nitrogen atmosphere, feed methane gas at a flow rate of 5000mL / h, and at the same time raise the temperature to 900°C at a heating rate of 4°C / min, keep it for 1h, take it out after natural cooling, and then Pickling, filtering and drying are carried out to obtain a graphitized carbon material.

[0092] Add 0.3 g of the above-prepared graphitized carbon material into a 25 mL measuring cylinder, shake it up and down, and finally obtain a tap density of 0.4 g / mL by visual inspection.

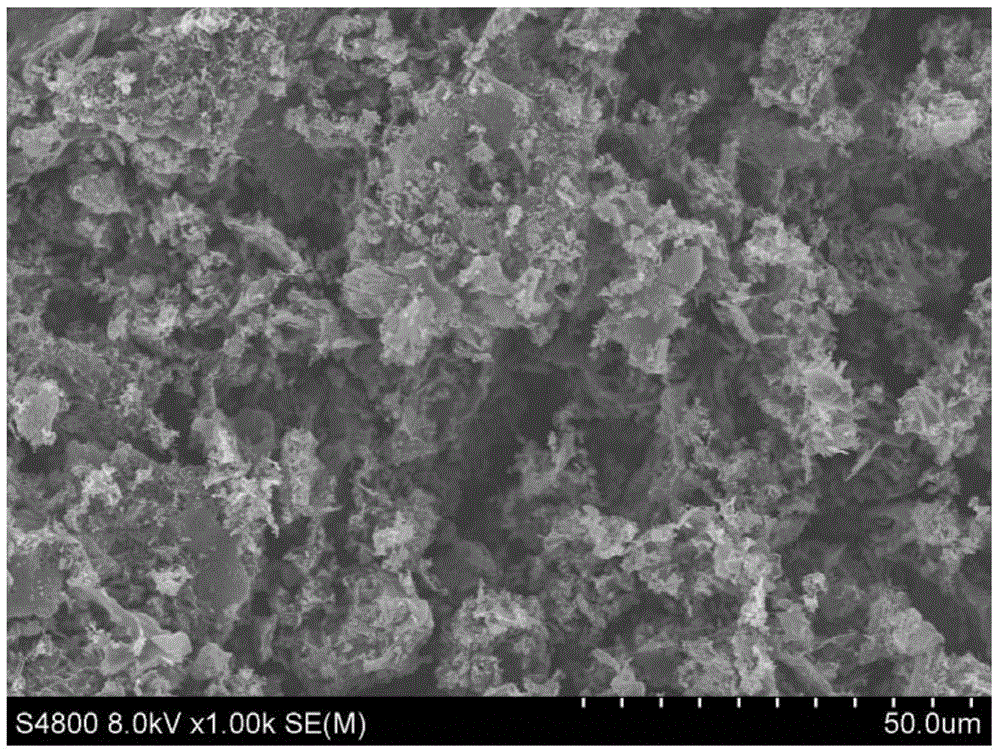

[0093] The specific surface area, porosity and average pore diameter of the above-mentioned graphitized carbon material are detected, and the result is: the specific surface area is 1500m 2 / g...

Embodiment 2

[0102] Get 100g phenolic resin (4169, Taiwan Changchun), it is immersed in the aqueous solution that contains 50g nickel sulfate in 200ml, dry, obtain the phenolic resin that adsorbs metal ion catalyst; solution, dried and pulverized to obtain a precursor.

[0103] Take 1000g of melamine and the precursor and mix it evenly, then place it in a tube furnace, in a nitrogen atmosphere, raise the temperature to 850°C at a rate of 4°C / min, keep it for 6h, take it out after natural cooling, and then carry out pickling, filtration, Dry to obtain a graphitized carbon material.

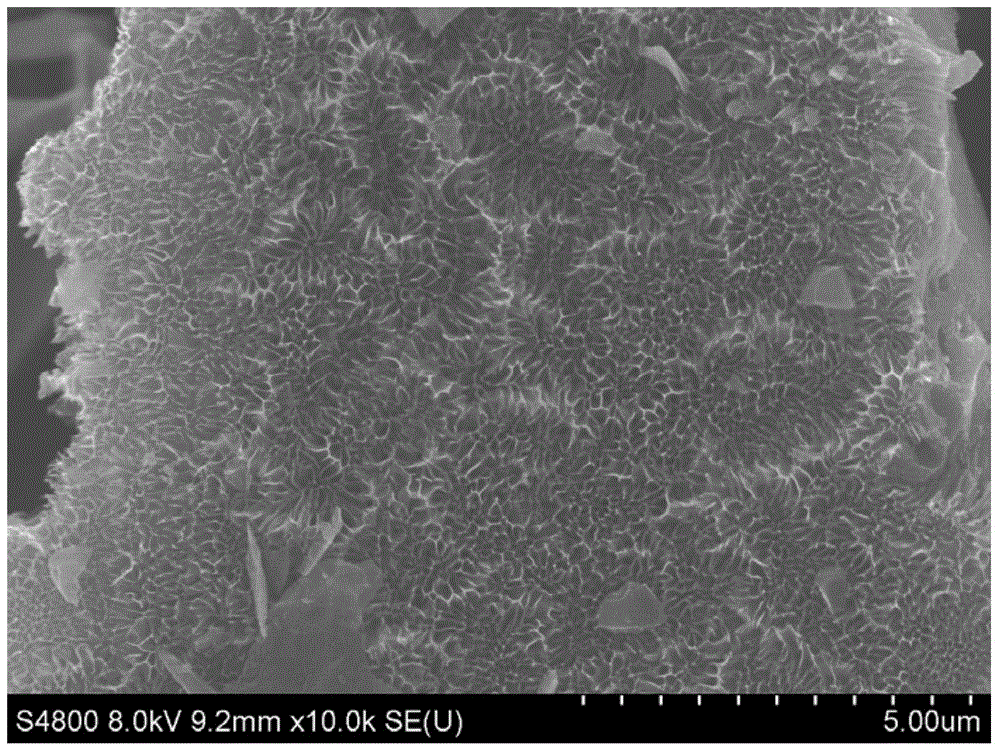

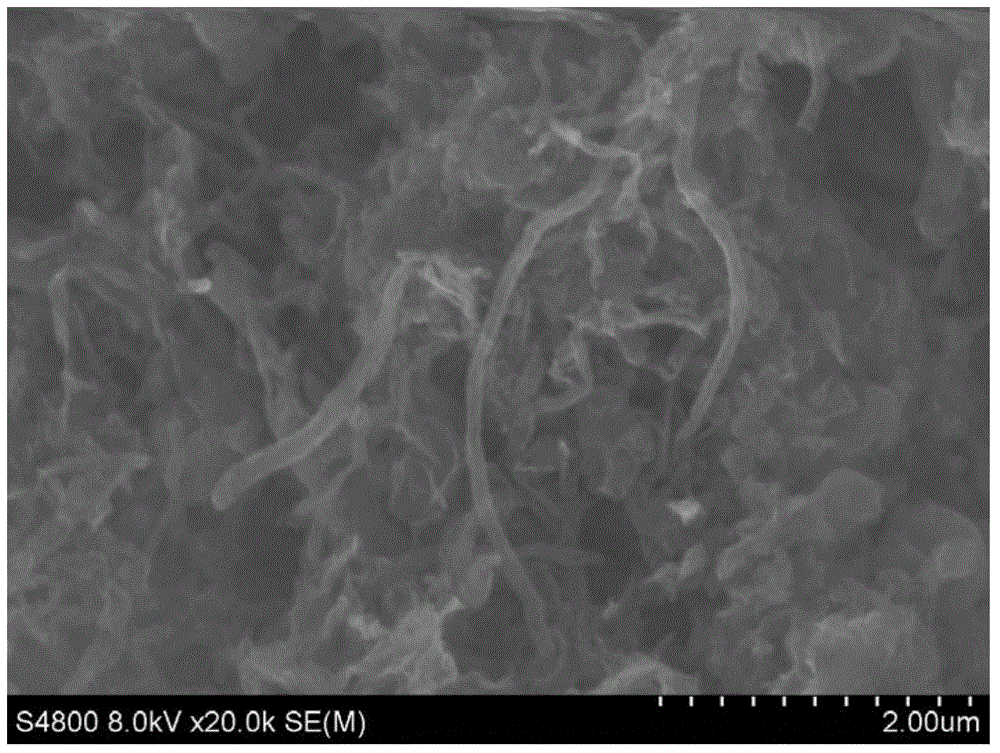

[0104] Scanning electron microscope (SEM) test is carried out to above-mentioned graphitized carbon material that makes, the result is as follows figure 2 shown. figure 2 For the SEM figure of the graphitized carbon material that the embodiment of the present invention 2 obtains, by figure 2 It can be seen that one-dimensional carbon nanotubes with a diameter of 20-100 nm are grown in situ on the surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com