Method for preparing polyphenylene sulfide/graphene composite material

A graphene composite and polyphenylene sulfide technology, applied in the field of chemical synthesis, can solve the problems of poor dispersion of reduced graphene, and achieve the effects of easy regulation of molecular distribution, small amount of solvent, and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] The invention provides a kind of preparation method of polyphenylene sulfide / graphene composite material, it is characterized in that described preparation method comprises the following steps:

[0016] (1) Add 5-10 g of graphene oxide and 85-100 g of PPS into 100-200 mL of solvent A, heat and stir at 220-300 ° C until the graphene oxide and PPS are fully dissolved to obtain a dispersion of graphene oxide and PPS;

[0017] (2) Add 0.1-2mol reducing agent to the graphene oxide and PPS dispersion obtained in step (1), react at 220-300°C for 0.1-4h, obtain reduced graphene and PPS dispersion, cool to 150-190°C , filter the reduced graphene and PPS dispersion, wash the filter cake to remove the solvent A and the remaining reducing agent, and dry at 80-260°C for 0.5-96h to obtain the graphene / PPS composite material.

[0018] Above-mentioned steps (1), (2) are to react under normal pressure-50 standard atmospheric pressure.

[0019] The solvent A is N-alkyl caprolactams such...

Embodiment 1

[0024] In a 0.5L three-neck flask, add 5g graphene oxide, 95gPPS and 200ml caprolactam, heat to 240°C under mechanical stirring, after the graphene oxide and PPS are fully dissolved, add 20g vitamin C to the reaction solution, then keep it for 30min, mix The solution turns from light yellow or brownish yellow to black solution, stop heating, and when the mixed solution is cooled to 180°C, filter the solution with 200-400 mesh steel wire mesh, wash the filter cake with ethanol and ion water for 2-3 times respectively, and then filter the solution at 180°C ℃ vacuum drying for 12 hours to obtain graphene / PPS composite material powder.

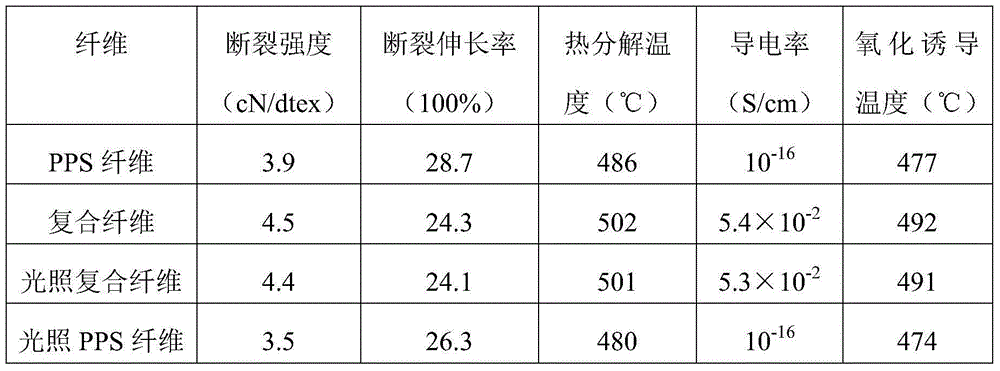

[0025] After the composite material powder is granulated, it is spun at 320°C to prepare graphene / PPS composite fibers. The composite fibers are heat-set in hot water at 100°C and drawn 3 times at 170°C. When the composite fiber was irradiated by a 45-watt xenon lamp for 12 hours, no decline in the mechanical properties of the fiber was observed, ...

Embodiment 2

[0028] In a 0.5L autoclave (5MPa), add 5g graphene oxide, 95gPPS and 200ml N-methylpyrrolidone, replace the air in the autoclave with nitrogen four times, heat to 280°C under mechanical stirring, after heating for 0.5h, dissolve 50ml Add 20g of vitamin C N-methylpyrrolidone solution into the reaction kettle with a metering pump, then keep it for 30 minutes, stop heating, and when the mixture is cooled to 180°C, filter the solution with 200-400 mesh steel mesh, and filter the cake with ethanol and ion After washing with water for 2 to 3 times, vacuum drying was carried out at 180°C for 12 hours to obtain graphene / PPS composite material powder.

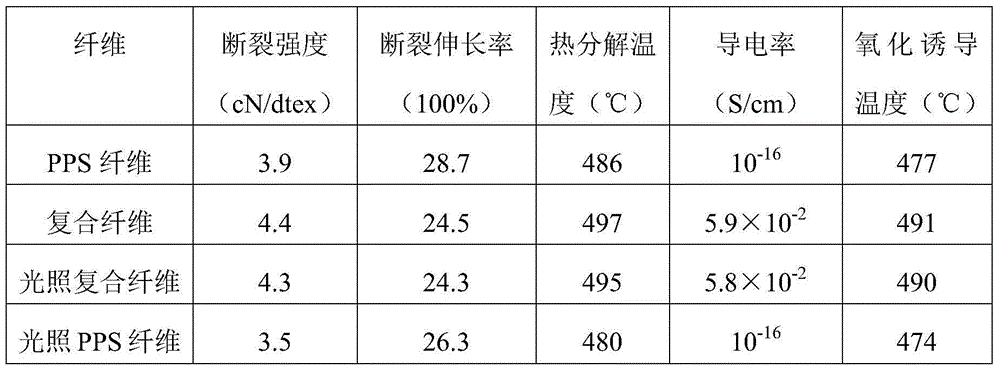

[0029]After the composite material powder is granulated, it is spun at 320°C to prepare graphene / PPS composite fibers. The composite fibers are heat-set in hot water at 100°C, and hot-drawn at 170°C for 3 times. When the composite fiber was irradiated by a 45-watt xenon lamp for 12 hours, no decline in the mechanical properties of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com