Production method for cation ultraviolet light curing frame glue used for organic electroluminescence displayer

A production method and luminescent technology, applied in circuits, adhesives, electrical components, etc., can solve the problems of low conversion rate of prepolymer synthesis, unstable reaction, unreasonable molecular weight and molecular weight distribution of prepolymer, etc., and achieve solidification and volatilization The effect of less inert gas, guaranteed life, and improved life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

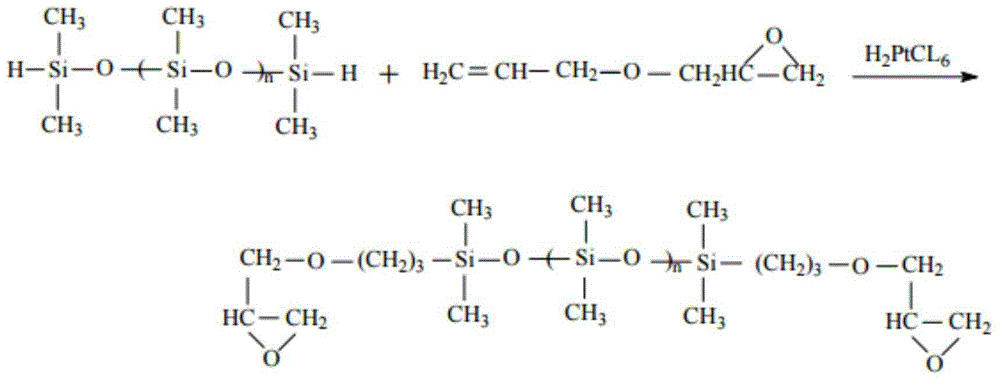

[0028] The production method of the cationic ultraviolet light curing sealant for the organic electroluminescent display in this embodiment comprises the following steps:

[0029] Step 1, using allyl glycidyl ether and hydrogen-terminated silicone oil as reaction raw materials, using chloroplatinic acid as a catalyst, weighing allyl glycidyl ether and hydrogen-terminated silicone oil in a molar ratio of 4:1, and chloroplatinic acid The amount is 0.018% of the total mass of allyl glycidyl ether and hydrogen-terminated silicone oil to weigh, and then the weighed allyl glycidyl ether, hydrogen-terminated silicone oil and chloroplatinic acid are added to the reaction kettle. Reaction under the condition of 85 ℃ for 8h, obtain the reaction product, carry out FIIR, XRD and GPC analysis respectively to the reaction product, know that this reaction product is polysiloxane modified epoxy resin by the analysis result, after testing, this embodiment The Gardner chroma of the polysiloxane...

Embodiment 2

[0034] The production method of the cationic ultraviolet light curing sealant for the organic electroluminescent display in this embodiment comprises the following steps:

[0035]Step 1, using allyl glycidyl ether and hydrogen-terminated silicone oil as reaction raw materials, using chloroplatinic acid as a catalyst, weighing allyl glycidyl ether and hydrogen-terminated silicone oil in a molar ratio of 4:1, and chloroplatinic acid The amount is 0.015% of the total mass of allyl glycidyl ether and hydrogen-terminated silicone oil to weigh, and then the weighed allyl glycidyl ether, hydrogen-terminated silicone oil and chloroplatinic acid are added to the reaction kettle. React under the condition of 82 ℃ for 9h, obtain the reaction product, carry out FIIR, XRD and GPC analysis to the reaction product respectively, know that this reaction product is polysiloxane modified epoxy resin by the analysis result, after testing, this embodiment The Gardner chroma of the polysiloxane mod...

Embodiment 3

[0040] The production method of the cationic ultraviolet light curing sealant for the organic electroluminescent display in this embodiment comprises the following steps:

[0041] Step 1, using allyl glycidyl ether and hydrogen-terminated silicone oil as reaction raw materials, using chloroplatinic acid as a catalyst, weighing allyl glycidyl ether and hydrogen-terminated silicone oil in a molar ratio of 5:1, and chloroplatinic acid Weigh it in an amount of 0.01% of the total mass of allyl glycidyl ether and hydrogen-terminated silicone oil, then add the weighed allyl glycidyl ether, hydrogen-terminated silicone oil and chloroplatinic acid into the reaction kettle, and React under the condition of 90 ℃ for 6h, obtain the reaction product, carry out FIIR, XRD and GPC analysis to the reaction product respectively, know that this reaction product is polysiloxane modified epoxy resin by the analysis result, after testing, this embodiment The Gardner color of the polysiloxane modifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com