Method for preparing graphene/carbon nanotube composites by solid-phase cracking technology

A technology of carbon nanotubes and composite materials, applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., can solve the problems of high cost, poor quality, low efficiency, etc., and achieve energy saving, high safety, cracking The effect of low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

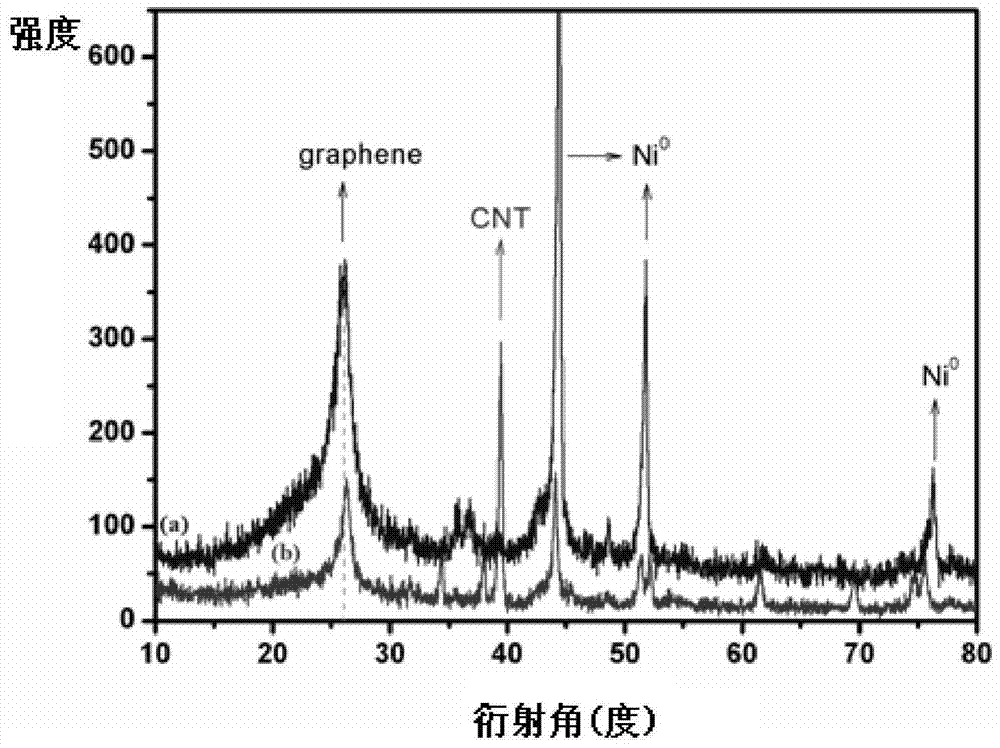

[0033] Using 30.0 grams of self-made nickel phthalocyanine (the amount of nickel chloride precursor is 0.5 grams) as the starting material, in a quartz tube furnace, under the protection of high-purity argon, the argon flow rate is controlled at 50cm 3 min -1 , cracked under the following heating scheme to obtain about 23 grams of the final graphene / carbon nanotube composite material. That is, the temperature is raised to 300 degrees at a slow heating rate of 5 degrees per minute, and 300 degrees is stable for 1 hour; the temperature is raised to 350 degrees at 5 degrees per minute, and 350 degrees is stable for 1 hour; hour; the temperature is raised to 500 degrees at 3 degrees per minute, and 500 degrees is stable for 4 hours; the temperature is raised to 800 degrees at 2 degrees per minute, and 800 degrees is stable for 8 hours, and finally it is naturally lowered to room temperature. Its XRD pattern is as figure 1 shown.

Embodiment 2

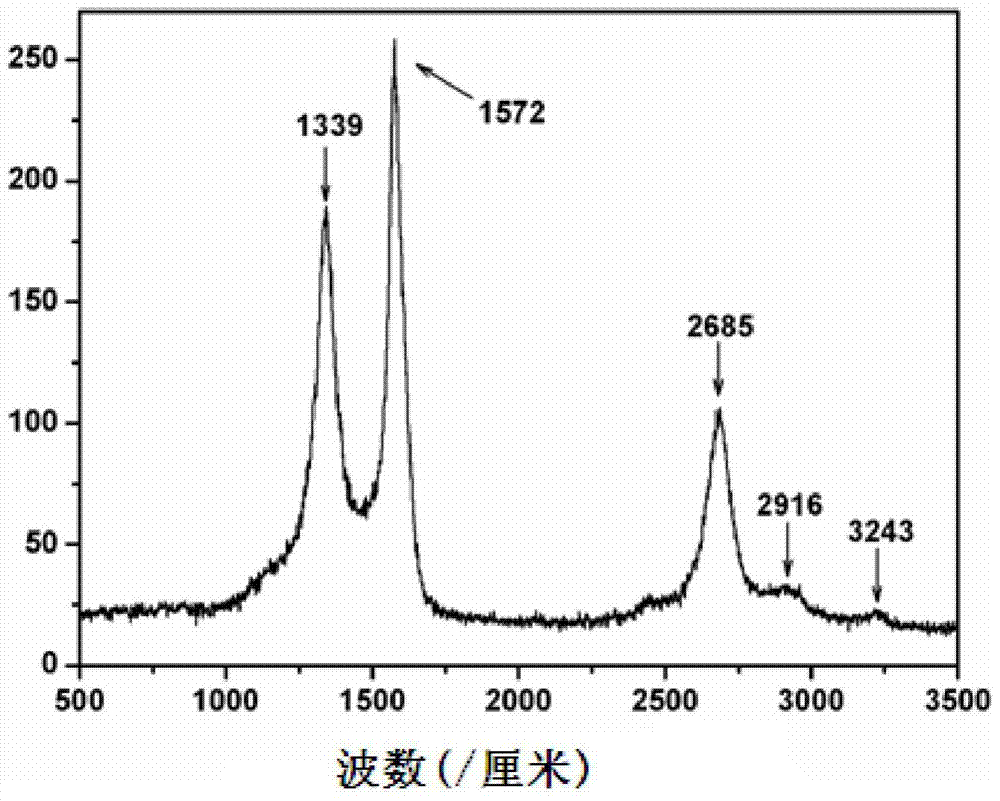

[0035] Using 30.0 grams of self-made nickel phthalocyanine (1.65 grams of nickel chloride precursor) as the starting material, in a quartz tube furnace, under the protection of high-purity argon, the argon flow rate is controlled at 50cm 3 min -1 , cracked under the following heating scheme to obtain about 22 grams of the final graphene / carbon nanotube composite material. That is, the temperature is raised to 300 degrees at a slow heating rate of 5 degrees per minute, and 300 degrees is stable for 1 hour; the temperature is raised to 350 degrees at 5 degrees per minute, and 350 degrees is stable for 1 hour; hour; the temperature is raised to 500 degrees at 3 degrees per minute, and 500 degrees is stable for 4 hours; the temperature is raised to 800 degrees at 2 degrees per minute, and 800 degrees is stable for 8 hours, and finally it is naturally lowered to room temperature. Its Raman spectrum is as follows figure 2 shown.

Embodiment 3

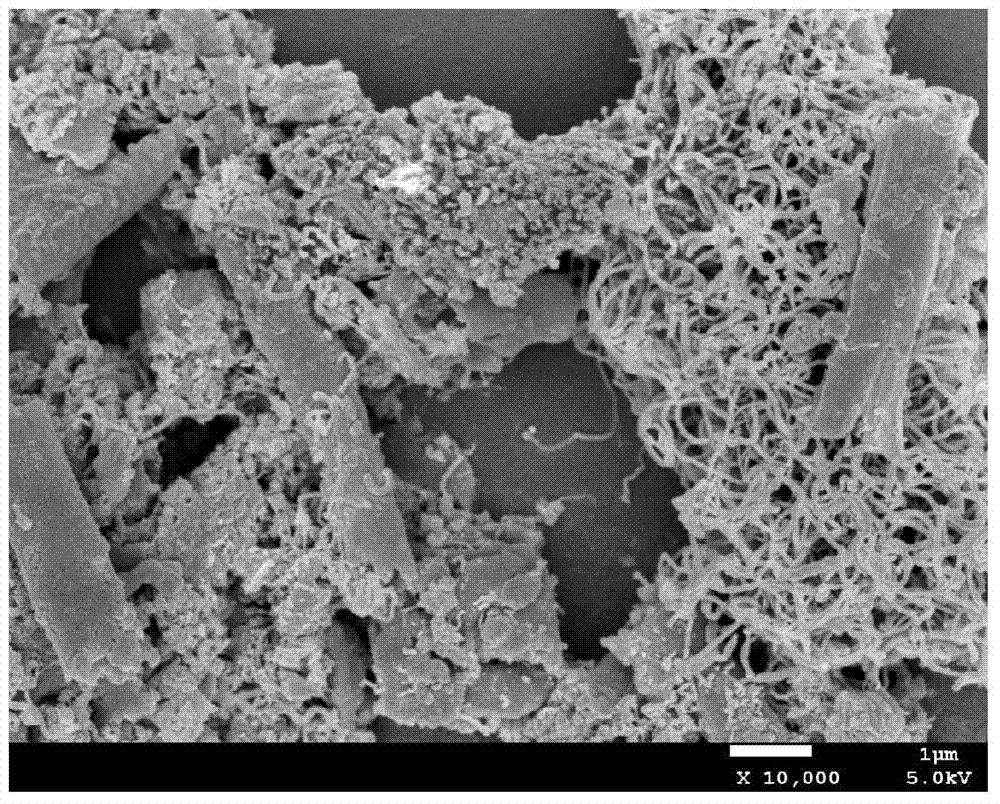

[0037] Using 30.0 grams of self-made nickel phthalocyanine (1.0 grams of nickel chloride precursor) as the starting material, in a quartz tube furnace, under the protection of high-purity argon, the argon flow rate is controlled at 50cm 3 min -1 , and obtain about 20 grams of final graphene / carbon nanotube composite material by pyrolysis under the following heating scheme. That is, the temperature is raised to 300 degrees at a slow heating rate of 5 degrees per minute, and 300 degrees is stable for 1 hour; the temperature is raised to 350 degrees at 5 degrees per minute, and 350 degrees is stable for 1 hour; hour; the temperature is raised to 500 degrees at 3 degrees per minute, and 500 degrees is stable for 4 hours; the temperature is raised to 800 degrees at 2 degrees per minute, and 800 degrees is stable for 8 hours, and finally it is naturally lowered to room temperature. Its SEM and TEM images are as follows image 3 , as shown in 4.

[0038] The sample of Example 3 wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com