Preparation method of high-density Fe(Se,Te) superconducting material

A superconducting material and high-density technology, applied in the manufacture/processing of superconductor devices, superconductor components, etc., can solve problems such as consumption, poor sintering efficiency, and low density, and achieve short process flow, strong repeatability, and avoid melting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment includes the following steps:

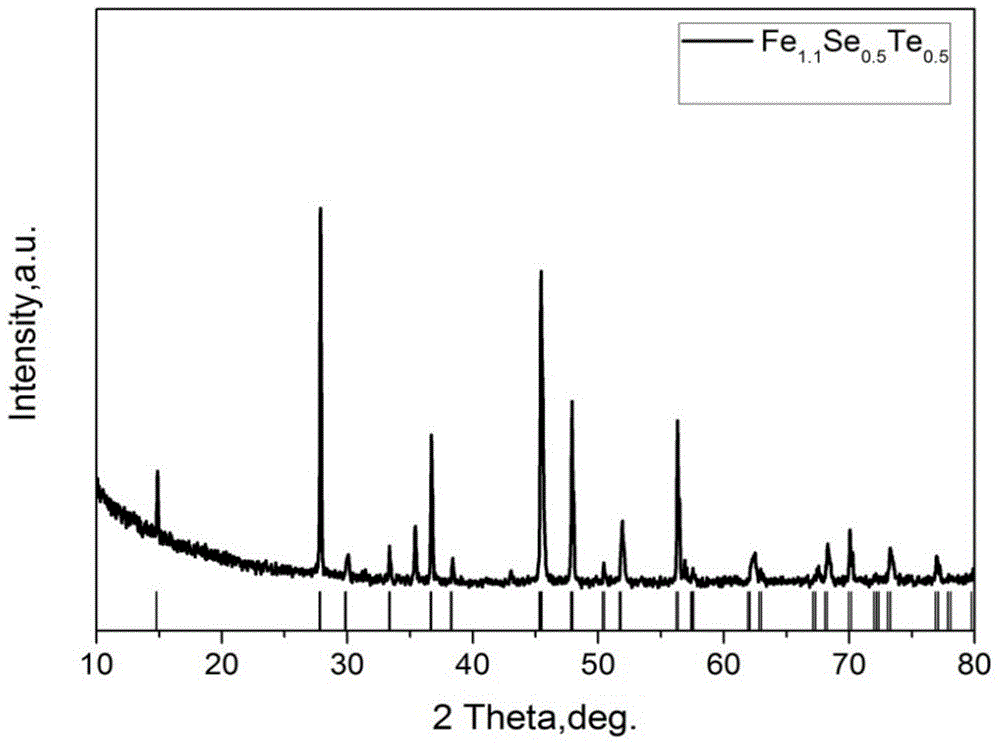

[0034] Step 1. In a glove box filled with an inert gas, place the mixed powder in a vacuum ball mill jar, then seal the vacuum ball mill jar and take it out; the mixed powder is composed of iron powder with a molar ratio of 1.1:0.5:0.5, Selenium powder and tellurium powder are mixed; the iron powder is reduced iron powder, the mass purity of the iron powder is not less than 99%, the mass purity of the selenium powder is not less than 99%, and the mass purity of the tellurium powder is Purity not less than 99%;

[0035] Step 2. Place the vacuum ball milling tank containing the mixed powder in step 1 in a high-energy ball mill for high-energy ball milling. The specific process is:

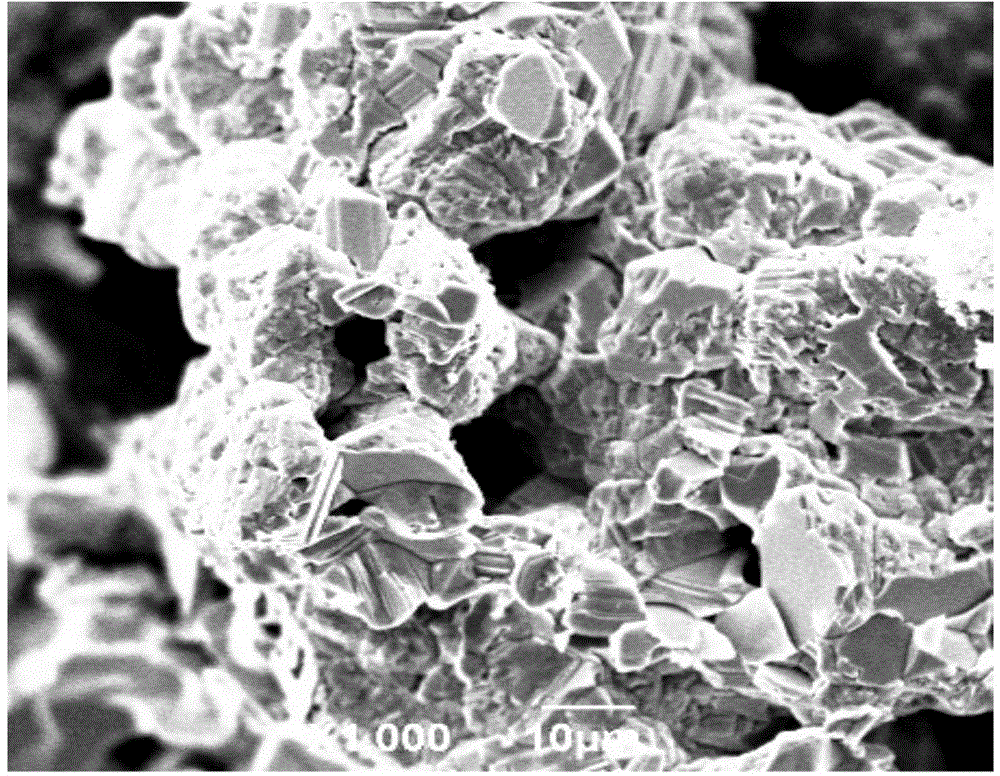

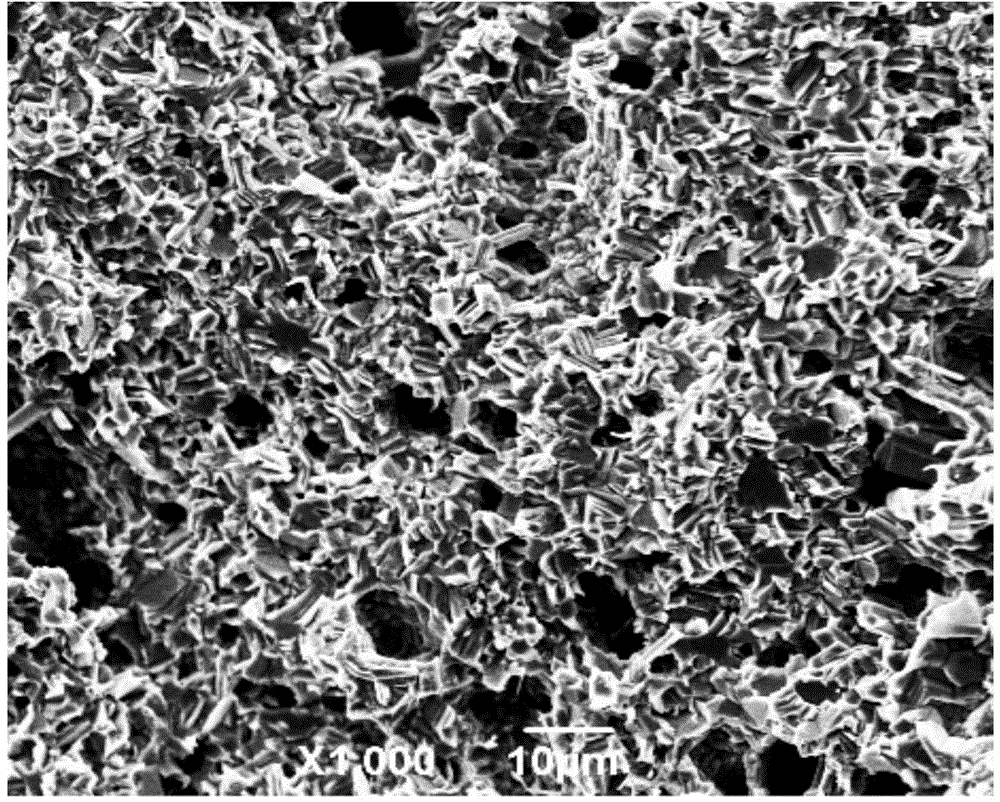

[0036] Step 201: Under the condition that the rotating speed of the high-energy ball mill is 1740r / min, the mixed powder is subjected to high-energy ball milling treatment for 10 minutes, and then the vacuum ball milling tank is taken out and so...

Embodiment 2

[0042] This embodiment includes the following steps:

[0043] Step 1. In a glove box filled with an inert gas, place the mixed powder in a vacuum ball mill jar, then seal the vacuum ball mill jar and take it out; the mixed powder is composed of iron powder with a molar ratio of 1.2:0.5:0.5, Selenium powder and tellurium powder are mixed; the iron powder is reduced iron powder, the mass purity of the iron powder is not less than 99%, the mass purity of the selenium powder is not less than 99%, and the mass purity of the tellurium powder is Purity not less than 99%;

[0044] Step 2. Place the vacuum ball milling tank containing the mixed powder in step 1 in a high-energy ball mill for high-energy ball milling. The specific process is:

[0045] Step 201: Under the condition that the speed of the high-energy ball mill is 1800r / min, the mixed powder is high-energy ball milled for 20 minutes, and then the vacuum ball mill tank is taken out and soaked in liquid nitrogen to cool; Th...

Embodiment 3

[0051] This embodiment includes the following steps:

[0052] Step 1. In a glove box filled with an inert gas, place the mixed powder in a vacuum ball mill jar, then seal the vacuum ball mill jar and take it out; the mixed powder is composed of iron powder with a molar ratio of 1.0:0.3:0.7, Selenium powder and tellurium powder are mixed; the iron powder is reduced iron powder, the mass purity of the iron powder is not less than 99%, the mass purity of the selenium powder is not less than 99%, and the mass purity of the tellurium powder is Purity not less than 99%;

[0053] Step 2. Place the vacuum ball milling tank containing the mixed powder in step 1 in a high-energy ball mill for high-energy ball milling. The specific process is:

[0054] Step 201: Under the condition that the rotating speed of the high-energy ball mill is 1500r / min, the mixed powder is subjected to high-energy ball milling treatment for 30 minutes, and then the vacuum ball mill tank is taken out and soake...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Superconducting transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com