Large Pi system polyimide cross-linked polymer for negative electrode of lithium ion battery

A technology of cross-linked polymer and polyimide, applied in battery electrodes, secondary batteries, circuits, etc., to achieve the effects of simple and easy preparation process, mild synthesis conditions and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

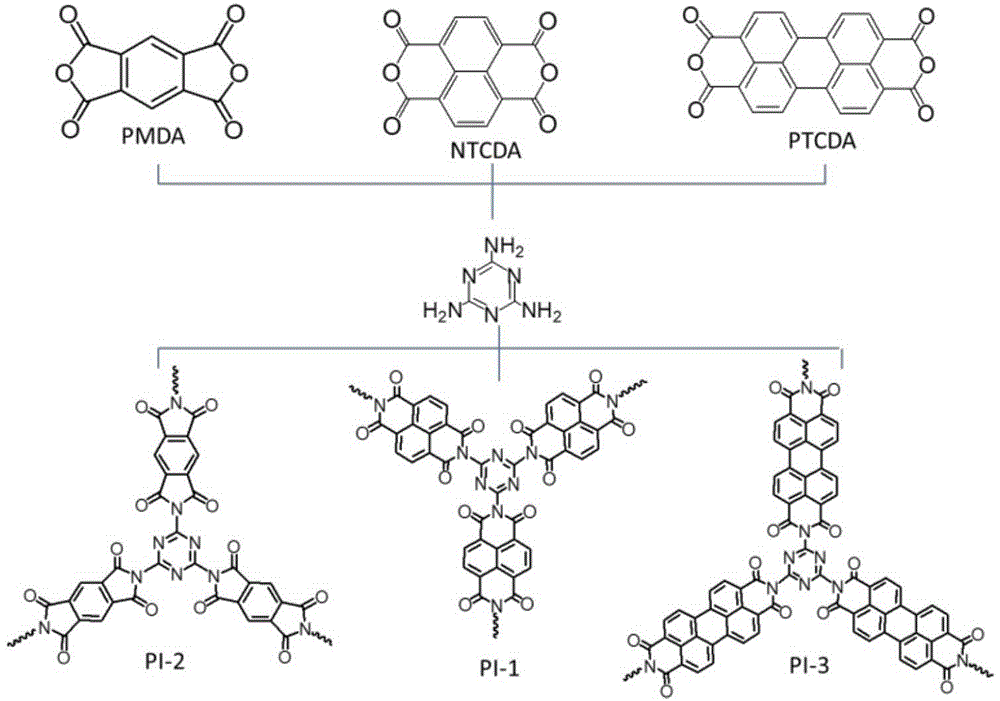

[0031] 1) Take 10mmol of 1,4,5,8-naphthalene methanecarboxylic dianhydride and 15mmol of melamine in a 150mL round bottom flask, add 50mL of N,N-dimethylformamide solution, and stir until the solids are evenly mixed. Under the protection of nitrogen, the reaction was heated to reflux and stirred overnight. Cool to room temperature, filter with suction, wash with absolute ethanol, and dry under vacuum at 75°C for 10h. Heat treatment at 300-500°C for 1-8h in a nitrogen atmosphere. The obtained polymer material was designated as PI-1.

[0032] 2) Preparation of lithium-ion battery negative electrode

[0033] Weigh the above polyimide material (active material), acetylene black, polyvinylidene fluoride (PVDF) (PVDF is dissolved in N-methylpyrrolidone in advance) according to the mass ratio of 5:3:2, and mix the three evenly to form Slurry: Apply the slurry evenly on the copper foil, dry it at 120°C, compact the pole piece, and cut it into thin slices with a diameter of 16mm to ...

Embodiment 2

[0036] 1) Take 10mmol of pyromellitic dianhydride and 15mmol of melamine in a 150mL round bottom flask, add 50mL of N,N-dimethylformamide solution, and stir until the solids are evenly mixed. Under the protection of nitrogen, the reaction was heated to reflux and stirred overnight. Cool to room temperature, filter with suction, wash with absolute ethanol, and dry under vacuum at 75°C for 10h. Heat treatment at 300-500°C for 1-8h in a nitrogen atmosphere. The resulting polymer material was designated as PI-2.

[0037] 2) Preparation of lithium-ion battery negative electrode

[0038] Weigh the above polyimide material (active material), acetylene black, polyvinylidene fluoride (PVDF) (PVDF is dissolved in N-methylpyrrolidone in advance) according to the mass ratio of 5:3:2, and mix the three evenly to form Slurry: Apply the slurry evenly on the copper foil, dry it at 120°C, compact the pole piece, and cut it into thin slices with a diameter of 16mm to make the pole piece. Af...

Embodiment 3

[0041]1) Take 10mmol of 3,4,9,10-perylenetetracarboxylic dianhydride (PTCDA) and 15mmol of melamine in a 150mL round bottom flask, add 50mL of N-methylpyrrolidone, and stir until the solids are evenly mixed. Under the protection of nitrogen, the reaction was heated to reflux and stirred overnight. Cool to room temperature, filter with suction, wash with absolute ethanol, and dry under vacuum at 75°C for 10h. Heat treatment at 300-500°C for 1-8h in a nitrogen atmosphere. The resulting polymer material was designated as PI-3.

[0042] 2) Preparation of lithium-ion battery negative electrode

[0043] Weigh the above polyimide material (active material), acetylene black, polyvinylidene fluoride (PVDF) (PVDF is dissolved in N-methylpyrrolidone in advance) according to the mass ratio of 5:3:2, and mix the three evenly to form Slurry: Apply the slurry evenly on the copper foil, dry it at 120°C, compact the pole piece, and cut it into thin slices with a diameter of 16mm to make the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com