Preparation method of <10>B-enriched zirconium diboride powder

A technology of zirconium diboride and zirconium dioxide is applied in the field of preparation of 10B-rich zirconium diboride powder, which can solve the problems of high product impurity content, high product purity, long production cycle, etc. The effect of high product purity and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] a kind of rich 10 The preparation method of B zirconium diboride powder, comprises the steps:

[0034] 1) Zirconium dioxide with a particle size of 5-35 μm and zirconia with a particle size of 5-35 μm 10 B boron carbide ( 10 Carbon black with a B abundance of 86% (at.)) and a particle size of 10 to 30 μm is mixed and stirred evenly at a molar ratio of 2:1.2:5 to obtain zirconia, rich 10 B mixture of boron carbide and carbon black;

[0035] 2) Stir the zirconia, rich 10 The mixture of B boron carbide and carbon black is placed in a graphite crucible;

[0036] 3) Place the crucible in a pressureless sintering furnace, under an argon atmosphere, heat the mixture at 1600°C, and conduct a compound reaction of the mixture. 10 B zirconium diboride powder material;

[0037] 4) The reaction product was wet ball milled for 8 hours to obtain an average particle size of 0.9 μm, rich in 10 B zirconium diboride powder.

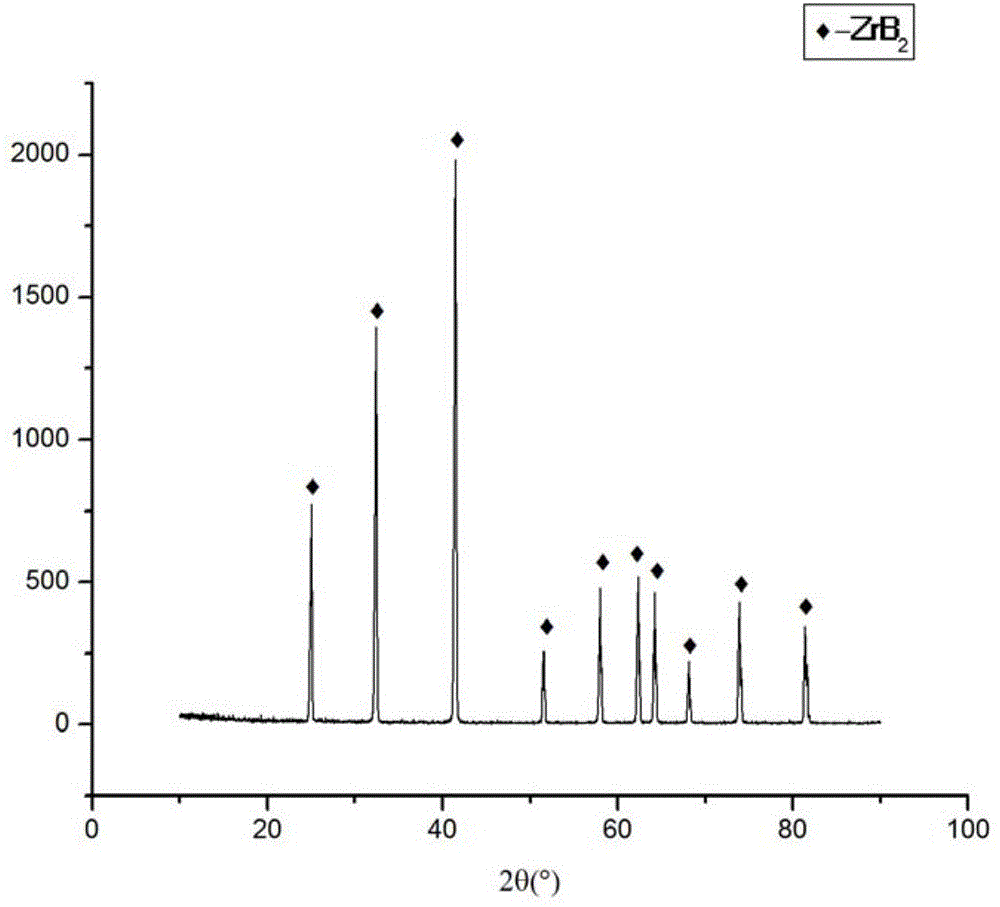

[0038] The rich obtained in this example 10 The partic...

Embodiment 2

[0040] a kind of rich 10 The preparation method of B zirconium diboride powder, comprises the steps:

[0041]1) Zirconium dioxide with a particle size of 5-35 μm and zirconia with a particle size of 5-35 μm 10 B boron carbide ( 10 Carbon black with B abundance of 92% (at.)) and particle size of 10 to 30 μm is mixed and stirred evenly in a molar ratio of 2:1.2:4 to obtain zirconia, rich 10 B mixture of boron carbide and carbon black;

[0042] 2) Stir the zirconia, rich 10 The mixture of B boron carbide and carbon black is placed in a graphite crucible;

[0043] 3) Place the crucible in a pressureless sintering furnace, under an argon atmosphere, at a heating temperature of 1700°C, and carry out a compound reaction of the mixture, and after holding for 0.7h, obtain 97% pure 10 B zirconium diboride powder material.

[0044] 4) The reaction product was wet ball milled for 10 hours to obtain an average particle size of 0.75 μm, rich in 10 B zirconium diboride powder.

[004...

Embodiment 3

[0047] a kind of rich 10 The preparation method of B zirconium diboride powder, comprises the steps:

[0048] 1) Zirconium dioxide with a particle size of 5-35 μm and zirconia with a particle size of 5-35 μm 10 B boron carbide ( 10 B carbon black with an abundance of 95% (at.)) and a particle size of 10 to 30 μm, mixed and stirred evenly in a molar ratio of 2:1.2:3.3 to obtain zirconia, rich in 10 A mixture of boron carbide and carbon black of B;

[0049] 2) Stir the zirconium dioxide, rich 10 The mixture of boron carbide and carbon black of B is placed in a graphite crucible;

[0050] 3) Place the crucible in a pressureless sintering furnace, and in an argon atmosphere, heat the mixture at 1800°C for a compound reaction. After keeping it for 1 hour, a 98% purity sintering compound is obtained. 10 B zirconium diboride powder material.

[0051] 4) The reaction product was wet ball milled for 12 hours to obtain an average particle size of about 0.65 μm, rich in 10 B zirco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com