Structural sealant for glass curtain wall and preparation method for structural sealant

A glass curtain wall and sealant technology, which is applied in the direction of chemical instruments and methods, adhesives, and other chemical processes, can solve the problems of low displacement capacity, poor adhesion, and low mechanical strength, and achieve good aging resistance and adhesion Good, excellent mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

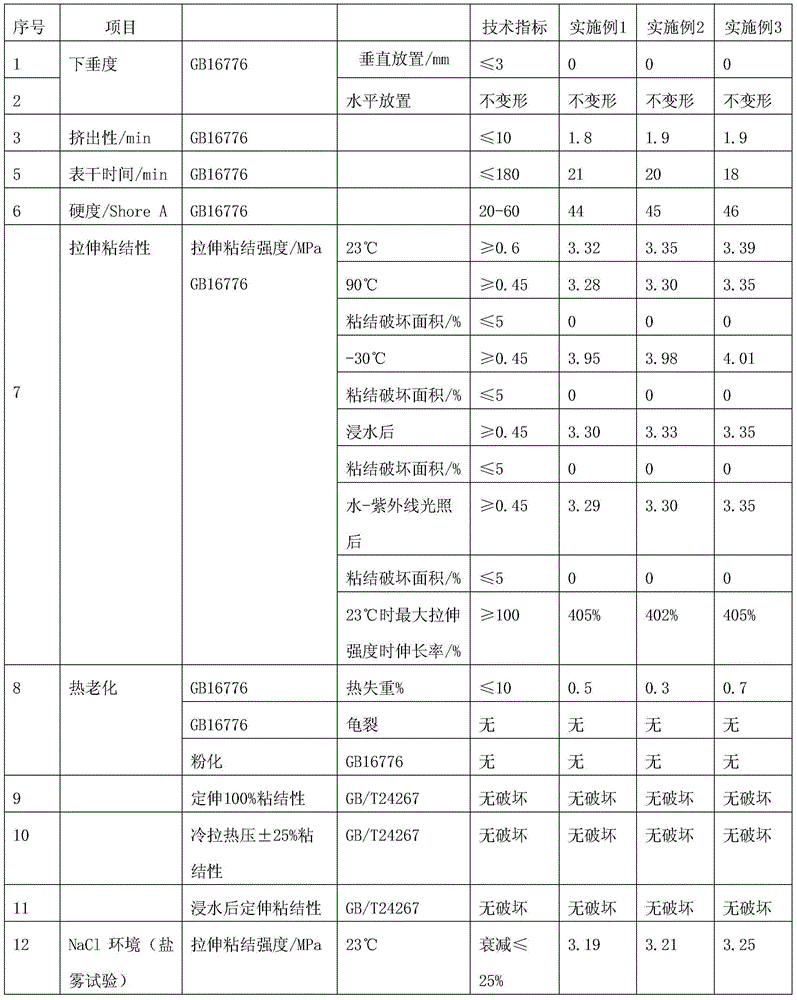

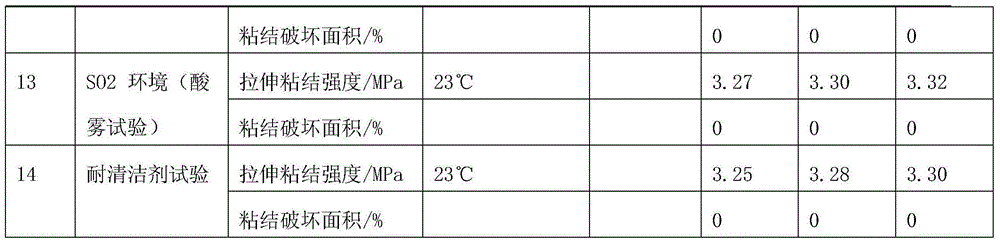

Examples

Embodiment 1

[0027] The formula of structural sealant for glass curtain wall is as follows:

[0028] 120kg of hydroxyl-terminated polydimethylsiloxane with a viscosity of 55000mPa·s, 70kg of hydroxyl-terminated polydimethylsiloxane with a viscosity of 4000mPa·s, 65kg of acrylic acid, 20kg of propylene tricarboxylic acid, 12kg of polypropylene powder, Bis(3,4-dimethylbenzylidene)sorbitol 0.08kg, trimethoxyboroxine 0.3kg, 2-amino-N-cyclohexylacetamide 0.1kg, vinyl tributylketoxime silane 0.9kg, ethylene glycol glycidyl ether 0.2kg, dibutyltin mercaptide 1.8kg, hollow glass microspheres 2.0kg, methyl tributylketoxime silane 0.10kg, 3-aminopropyltriethoxysilane 2kg , 2.4kg of dibutyltin dilaurate and 0.01kg of ammonium persulfate.

[0029] Wherein, the particle size of the hollow glass microspheres is 10 microns.

[0030] The preparation method comprises the following steps: (1), the hydroxyl-terminated polydimethylsiloxane with a viscosity of 55000mPa·s, the hydroxyl-terminated polydimethyl...

Embodiment 2

[0032]160kg of hydroxyl-terminated polydimethylsiloxane with a viscosity of 60000mPa·s, 80kg of hydroxyl-terminated polydimethylsiloxane with a viscosity of 3500mPa·s, 55kg of acrylic acid, 35kg of propylene tricarboxylic acid, 10kg of polypropylene powder, Bis(3,4-dimethylbenzylidene)sorbitol 0.05kg, trimethoxyboroxine 0.15kg, 2-amino-N-cyclohexylacetamide 0.06kg, vinyl tributylketoxime silane 0.5kg, ethylene glycol glycidyl ether 0.1kg, dibutyltin mercaptide 1.5kg, hollow glass microspheres 0.5kg, methyl tributylketoxime silane 0.12kg, 3-aminopropyltriethoxysilane 3kg , 2.2kg of dibutyltin dilaurate and 0.02kg of ammonium persulfate.

[0033] Wherein, the particle size of the hollow glass microspheres is 15 microns.

[0034] The preparation method comprises the following steps: (1), the hydroxyl-terminated polydimethylsiloxane with a viscosity of 60000mPa·s, the hydroxyl-terminated polydimethylsiloxane with a viscosity of 3500mPa·s, acrylic acid and propylene three Add car...

Embodiment 3

[0036] 140kg of hydroxyl-terminated polydimethylsiloxane with a viscosity of 65000mPa·s, 60kg of hydroxyl-terminated polydimethylsiloxane with a viscosity of 3000mPa·s, 60kg of acrylic acid, 30kg of propylene tricarboxylic acid, 5kg of polypropylene powder, Bis(3,4-dimethylbenzylidene) sorbitol 0.12kg, trimethoxyboroxine 0.25kg, 2-amino-N-cyclohexylacetamide 0.02kg, vinyltributanoximinosilane 0.7kg, ethylene glycol glycidyl ether 0.3kg, dibutyltin mercaptide 1.2kg, hollow glass microspheres 2.5kg, methyl tributylketoxime silane 0.08kg, 3-aminopropyltriethoxysilane 4kg , 1.5kg of dibutyltin dilaurate and 0.01kg of ammonium persulfate.

[0037] The particle size of the hollow glass microspheres is 30 microns.

[0038] The preparation method comprises the following steps: (1), the hydroxyl-terminated polydimethylsiloxane with a viscosity of 65000mPa·s, the hydroxyl-terminated polydimethylsiloxane with a viscosity of 3000mPa·s, acrylic acid and propylene three Add carboxylic aci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com