Boron-doped diamond film material on surface of graphite and preparation method thereof

A technology of boron-doped diamond and thin-film materials, which is applied in the field of graphite/metal/boron-doped diamond multilayer composite materials, can solve problems such as complicated operations, complicated procedures, and restrictions on the application of new materials for electrochemical electrodes, and achieve low cost and high efficiency. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

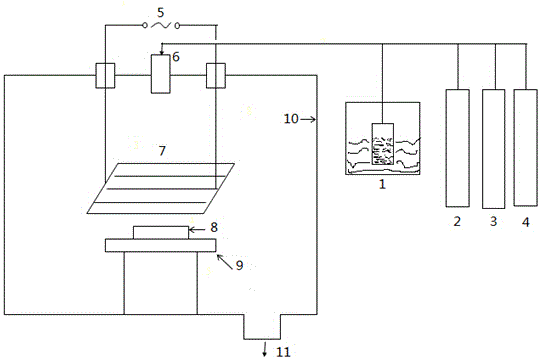

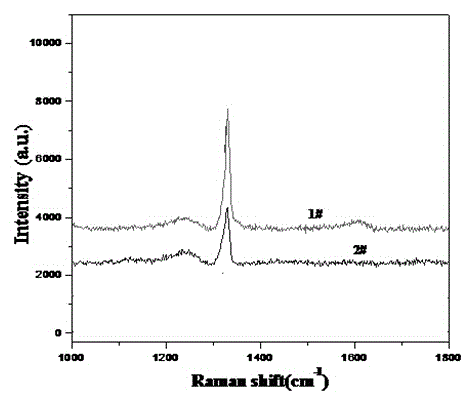

[0022] Turn on the power supply of the heated tungsten carbonyl constant temperature water bath in advance, adjust the temperature of the water bath to a constant temperature of 50°C; fix the graphite substrate on the water-cooled sample stage of the hot wire chemical vapor deposition system, pump the vacuum of the deposition chamber to a vacuum degree of 2.0 Pa, and Turn on the cooling water of the sample stage; start the hot wire power supply, increase the power of the power supply until the temperature of the hot wire reaches 1200°; open the adjusting needle valve on the tungsten carbonyl gas circuit for one-third of a turn, and pass the needle valve opening control amount into the vacuum chamber Carbonyl tungsten vapor; the above conditions are maintained for 1.5 hours to complete the growth of the tungsten intermediate layer. Close the needle valve on the tungsten carbonyl gas circuit, increase the power supply of the hot wire until the temperature of the hot wire reaches ...

Embodiment 2

[0024] Turn on the power supply of the heating tungsten carbonyl constant temperature water bath in advance, adjust the temperature of the water bath to a constant temperature of 50°C; fix the graphite cathode on the water-cooled sample stage of the hot wire chemical vapor deposition system, pump the vacuum of the deposition chamber to a vacuum degree of 2.0 Pa, and Turn on the cooling water of the sample stage; start the hot wire power supply, increase the power of the power supply until the temperature of the hot wire reaches 1200°; open the adjusting needle valve on the tungsten carbonyl gas circuit for one-third of a turn, and pass the needle valve opening control amount into the vacuum chamber Carbonyl tungsten vapor; the above conditions are maintained for 2 hours to complete the growth of the tungsten intermediate layer. Close the needle valve on the tungsten carbonyl gas circuit, increase the power supply of the hot wire until the temperature of the hot wire reaches 220...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com