Method and device for manufacturing surface porous heat transfer tubes

A technology of surface porous and manufacturing method, which is applied in the manufacture of heat exchange tubes, the manufacturing method and device of surface porous heat exchange tubes, can solve the problems of long sintering time, low efficiency and high energy consumption, and achieves light weight and high efficiency. , the effect of uniform pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for manufacturing a surface porous heat exchange tube, comprising the steps of:

[0030] a. Carry out pretreatment including dedusting and cleaning to the surface of the base pipe;

[0031] b. Metal powder, pore-forming agent and binder are 75-91% by weight of metal powder, 4-15% by weight of pore-forming agent, and 5-10% by weight of binder Mix uniformly to form a metal powder viscose coating; the metal powder is an alloy powder, and the alloy powder includes one or more of nickel-based alloy powder, iron-based alloy powder, cobalt-based alloy powder or copper-based alloy powder combination of species;

[0032] c. Coat the metal powder viscose coating on the surface of the base pipe with a coating thickness of 0.15~0.85mm;

[0033] d. Use an induction coil heating device for sintering. The induction coil adopts a hollow copper tube with an input medium frequency or high frequency alternating current (300-300000Hz or higher), and generates an alternating magn...

Embodiment 2

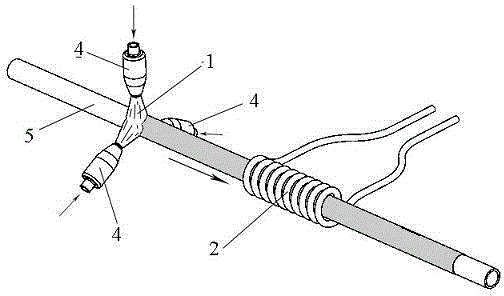

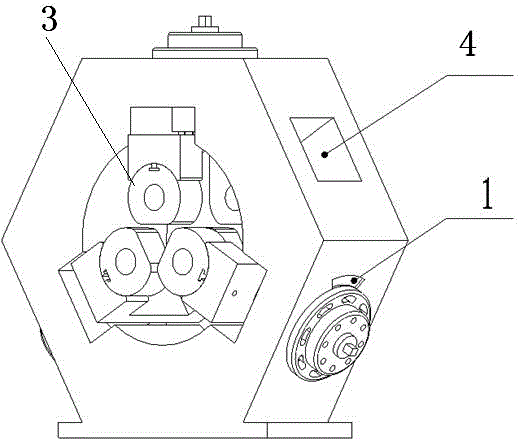

[0036] Such as figure 1 , 2 shown.

[0037] A device for manufacturing surface porous heat exchange tubes, which includes a fixed mounting base 1 and an induction coil 2, such as figure 1 As shown, one end of the fixed mounting base 1 is equipped with a friction feeding rod mechanism 3, and the other end is equally divided with nozzles 4, as shown in figure 2 As shown, the friction feeding rod mechanism is composed of a tapered friction roller and a driving mechanism. The number of said tapered friction rollers is three, and they are evenly distributed in the central hole in the fixed installation. Between the axes of the three tapered friction rollers The distance between them can be adjusted to meet the needs of different substrate diameters. The driving mechanism drives the conical friction roller to rotate and uses the friction force to push the base tube 5 forward so that the base tube sprayed by the nozzle enters the induction coil 2 for rapid heating and curing. Th...

Embodiment 3

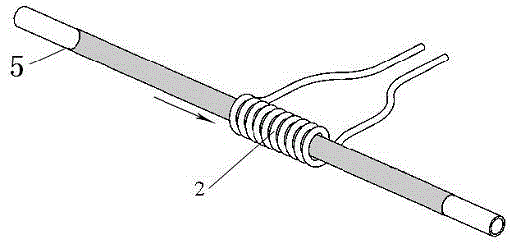

[0039] Such as image 3 shown.

[0040] The difference between this embodiment and the second embodiment is the combination of manpower and machinery. First, the configured metal powder bonding paint is manually coated on the surface of the base tube, and the base tube is linearly moved into the induction coil by an additional tube delivery mechanism. , is heated to a predetermined temperature by the coil, kept for a short time, and starts to cool after leaving the coil, that is, the surface porous layer is obtained, and the processing and manufacturing of the surface porous heat exchange tube is completed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com