Conductive carbon paste, carbon counter electrode, battery and preparation method for perovskite solar cell

A technology for solar cells and conductive carbon paste, which is used in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, and semiconductor/solid-state device manufacture, etc. It can solve problems that hinder photoelectric conversion efficiency and corrode perovskite films. , can not be directly applied to the preparation of perovskite solar cells, etc., to achieve the effect of good conductivity, beneficial to collection, and low square resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

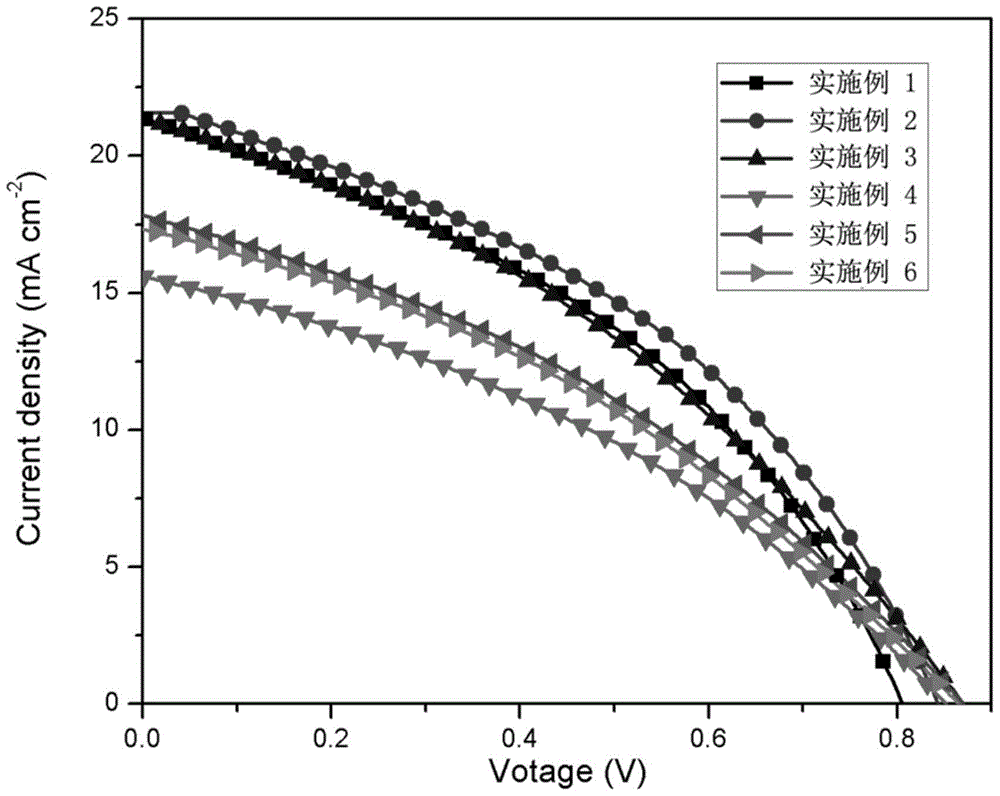

Examples

Embodiment 1

[0031] This example is used to prepare conductive carbon paste.

[0032] S1: magnetic stirring at 50° C. for 3 hours, dissolving the binder in an organic solvent to form a transparent fluid solution; the binder is acrylic resin and ethyl cellulose; the solvent is toluene. The binder accounts for 10% by mass of the conductive carbon paste. The conductive filler accounts for 15% by mass of the conductive carbon paste; the inorganic additive accounts for 3.5% by mass of the conductive carbon paste.

[0033] S2: Perform ball milling on the mixed powder of conductive filler and inorganic additive to obtain a uniformly mixed powder; the inorganic additive is ZrO 2 powder, ZrO 2The particle size is 40nm, and the conductive filler includes nano-carbon black powder and flaky graphite powder, the mass ratio of which is 1:4, the particle size of the nano-carbon black powder is 40nm, and the particle size of the flaky graphite powder is 1 μm.

[0034] S3: Put the uniformly mixed powder...

Embodiment 2

[0036] This example is used to prepare conductive carbon paste.

[0037] S1: magnetic stirring at 60° C. for 4 hours, the binder is dissolved in an organic solvent to form a transparent fluid solution; the binder is acrylic resin and ethyl cellulose; the solvent is ethyl acetate. The binder accounts for 6% by mass of the conductive carbon paste, the conductive filler accounts for 20% by mass of the conductive carbon paste, and the inorganic additive accounts for 5% by mass of the conductive carbon paste.

[0038] S2: Perform ball milling on the mixed powder of conductive filler and inorganic additive to obtain a uniformly mixed powder; the inorganic additive is ZrO 2 , ZrO 2 The particle size of the powder is 50nm, the conductive filler includes nano-carbon black powder and flaky graphite powder, the mass ratio is 1:3, the particle size of the nano-carbon black powder is 30nm, and the particle size of the flaky graphite powder is 3 μm .

[0039] S3: Put the uniformly mixed ...

Embodiment 3

[0041] This example is used to prepare conductive carbon paste.

[0042] S1: magnetic stirring at 70° C. for 4 hours, the binder is dissolved in an organic solvent to form a transparent fluid solution; the binder is acrylic resin and ethyl cellulose; the solvent is ethyl acetate. The binder accounts for 15% by mass of the conductive carbon paste, the conductive filler accounts for 18% by mass of the conductive carbon paste, and the inorganic additive accounts for 3% by mass of the conductive carbon paste.

[0043] S2: Perform ball milling on the mixed powder of conductive filler and inorganic additive to obtain a uniformly mixed powder; the inorganic additive is NiO, the particle size of NiO powder is 30nm, and the conductive filler includes nano-carbon black powder and flaky graphite powder, and its mass ratio is 1:3, the particle size of the nano-carbon black powder is 50nm, and the particle size of the flaky graphite powder is 5 μm.

[0044] S3: Put the uniformly mixed pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com