Preparation of sulfur-tolerant methanation catalyst based on SBA-16 and application of the catalyst in preparation of SNG

A SBA-16, sulfur-resistant methanation technology, applied in physical/chemical process catalysts, molecular sieve catalysts, hydrocarbon production from carbon oxides, etc., can solve problems such as obstacles and catalyst activity reduction, and achieve single and reliable technology and system heat dissipation Few, easy-to-grasp effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

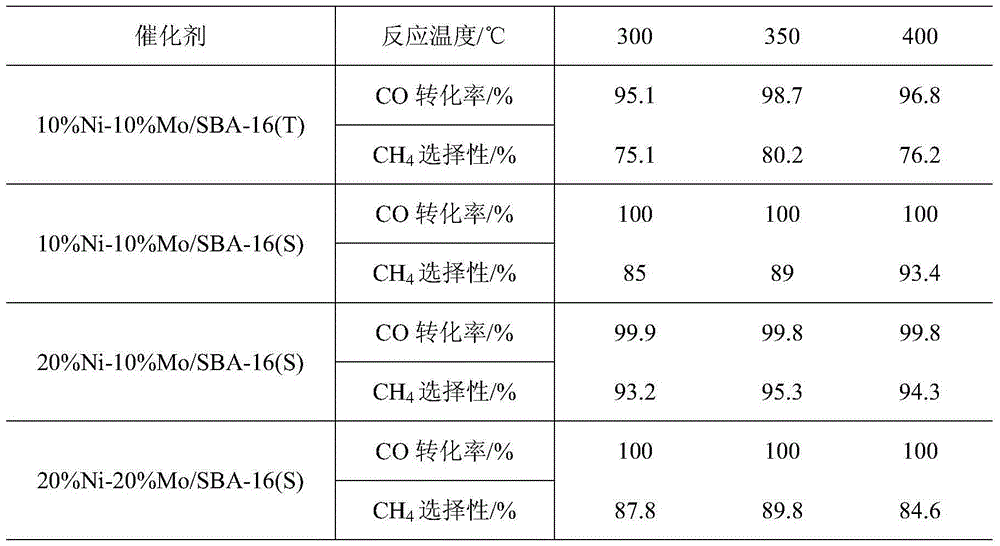

Embodiment 1

[0027] This example is used to illustrate that the present invention provides a sulfur-tolerant methanation catalyst and a preparation method thereof.

[0028] Weigh 0.619g of nickel nitrate hexahydrate and 0.230g of ammonium molybdate tetrahydrate and dissolve them in 1.5g of deionized water to prepare a mixed solution of nickel nitrate and ammonium molybdate. Then 1.0 g of mesoporous molecular sieve SBA-16 was weighed, and the carrier SBA-16 was impregnated in the mixed solution at room temperature by an equal-volume impregnation method. Then it was transferred to a vacuum oven at room temperature for vacuum impregnation overnight for 8 hours, and then it was dried in vacuum at a temperature of 50° C. for 6 hours. The resulting solid product is roasted in a muffle furnace at a temperature of 500°C for 5 hours. After being ground in a mortar, it is filtered with a 100-mesh sieve to obtain 10wt% nickel loading and 10wt% molybdenum loading. Sulfur-resistant methanation catalys...

Embodiment 2

[0030] This example is used to illustrate that the present invention provides a sulfur-tolerant methanation catalyst and a preparation method thereof.

[0031]Weigh 1.415g nickel nitrate hexahydrate to prepare nickel nitrate solution. Then 1.0 g of mesoporous molecular sieve SBA-16 was weighed, and the carrier SBA-16 was impregnated in an aqueous solution of nickel nitrate at room temperature by an equal-volume impregnation method. Then transfer it to a vacuum oven at room temperature for vacuum impregnation overnight for 8 hours, and then vacuum-dry it at a temperature of 50° C. for 6 hours. The resulting solid product was roasted in a muffle furnace at a temperature of 500°C for 5 hours. After being ground in a mortar, it was filtered with a 100-mesh sieve to obtain a powder with a Ni loading of 10wt%. Then weigh 0.263g of molybdenum Ammonium molybdate was formulated into ammonium molybdate solution, and then the above-mentioned synthesized powder was immersed in ammonium m...

Embodiment 3

[0033] This example is used to illustrate that the present invention provides a sulfur-tolerant methanation catalyst and a preparation method thereof.

[0034] Weigh 1.651g nickel nitrate hexahydrate to prepare nickel nitrate solution. Then 1.0 g of mesoporous molecular sieve SBA-16 was weighed, and the carrier SBA-16 was impregnated in an aqueous solution of nickel nitrate at room temperature by an equal-volume impregnation method. Then transfer it to a vacuum oven at room temperature for vacuum impregnation overnight for 8 hours, and then vacuum-dry it at a temperature of 50° C. for 6 hours. The resulting solid product was roasted in a muffle furnace at a temperature of 500°C for 5 hours. After being ground in a mortar, it was filtered with a 100-mesh sieve to obtain a powder with a Ni loading of 10wt%. Then weigh 0.613g of molybdenum Ammonium molybdate was formulated into ammonium molybdate solution, and then the above-mentioned synthesized powder was immersed in ammonium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com