Preparation method of probiotic fermentation cattle feed additive

A cattle feed and additive technology, applied in animal feed, animal feed, application and other directions, can solve the problems of pathogenic bacteria resistance, reduced beef quality, damage to cattle and human health, etc. Simple and effective in eliminating bad odors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

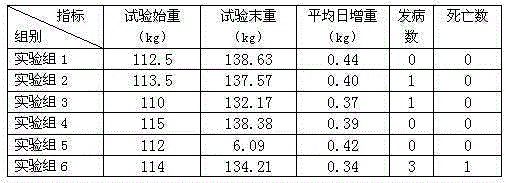

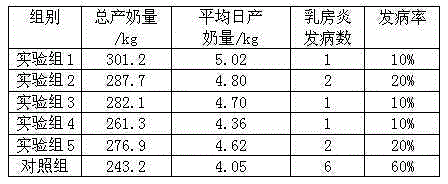

Examples

Embodiment 1

[0026] A method for preparing a cattle feed additive fermented by probiotics, which uses mulberry leaves, sudan grass, water hyacinth, hawthorn, purslane, licorice, sweet clover, rhubarb, and platycodon as raw materials, washes, dries in the shade, pulverizes, and sets aside; Take the pulverized raw materials and mix them uniformly according to the following parts by weight: 30 parts of mulberry leaves, 7 parts of sudan grass, 15 parts of water hyacinth, 10 parts of hawthorn, 20 parts of purslane, 11 parts of licorice, 7 parts of sweet clover, 6 parts of rhubarb 12 parts, Platycodon grandiflorum, make mixture, add equal weight water defibrination in the mixture, get slurry; Add and account for 4% bacillus subtilis and aspergillus niger of slurry total weight in the slurry, and bacillus subtilis and aspergillus oryzae The addition ratio is 1:2, stir, seal, and ferment for 3-10 days at a temperature of 27-32°C to obtain a fermentation stock solution; inoculate the fermentation st...

Embodiment 2

[0028] A method for preparing a cattle feed additive fermented by probiotics, which uses mulberry leaves, sudan grass, water hyacinth, hawthorn, purslane, licorice, sweet clover, rhubarb, and platycodon as raw materials, washes, dries in the shade, pulverizes, and sets aside; Take the raw materials that have been pulverized and mix evenly according to the following parts by weight: 20 parts of mulberry leaves, 10 parts of sudan grass, 10 parts of water hyacinth, 15 parts of hawthorn, 10 parts of purslane, 15 parts of licorice, 5 parts of sweet clover, 10 parts of rhubarb 10 parts, Platycodon grandiflorum, make mixture, add equal weight of water grinding in the mixture, get slurry; Add Bacillus subtilis and Aspergillus niger accounting for 3% of the total weight of slurry in the slurry, and Bacillus subtilis and Aspergillus oryzae The addition ratio is 1:2, stir, seal, and ferment for 3-10 days at a temperature of 27-32°C to obtain a fermentation stock solution; inoculate the fe...

Embodiment 3

[0030]A method for preparing a cattle feed additive fermented by probiotics, which uses mulberry leaves, sudan grass, water hyacinth, hawthorn, purslane, licorice, sweet clover, rhubarb, and platycodon as raw materials, washes, dries in the shade, pulverizes, and sets aside; Take the pulverized raw materials and mix them evenly according to the following parts by weight: 40 parts of mulberry leaves, 5 parts of Sudan grass, 20 parts of water hyacinth, 5 parts of hawthorn, 30 parts of purslane, 10 parts of licorice, 10 parts of sweet clover, 5 parts of rhubarb 15 parts, Platycodon grandiflorum, make mixture, add equal weight water grinding slurry in the mixture, add and account for 5% bacillus subtilis and aspergillus niger of slurry total weight in the slurry, and the content of bacillus subtilis and aspergillus oryzae The addition ratio is 1:2, stir, seal, and ferment for 3-10 days at a temperature of 27-32°C to obtain a fermentation stock solution; inoculate the fermentation s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com