Low temperature denitration catalyst for anti-SO2 and H2O poisoning and preparation method of same

A low-temperature denitrification and catalyst technology, which is applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as narrow temperature range and application limitations, and achieve improved dispersion, promotion of adsorption and activation, and enhanced surface Acid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

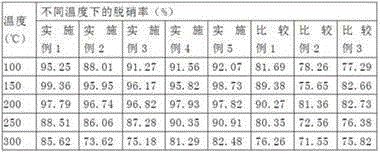

Examples

Embodiment 1

[0033] (1)Al 2 o 3 Sol preparation

[0034] Take 25 grams of pseudo-boehmite and add it to 200 g of deionized water, and add 10 g of concentrated nitric acid dropwise while stirring. After stirring for a certain period of time, heat to 80°C, add nitric acid dropwise until complete peptization, control the pH value of the solution at 3, and age for 24 hours to obtain a transparent aluminum sol.

[0035] (2) TiO 2 - Preparation of molecular sieve composite slurry

[0036] 26 g TiO 2 , 15 grams of molecular sieve and 3 grams of urea are mixed evenly, and 10 grams of Al 2 o 3 Sol, 200 grams of deionized water, and a concentration of 0.5mol L -1 Adjust the pH to 2 with nitric acid solution, stir vigorously for 2 hours, and age at room temperature for 12 hours to obtain TiO 2 - Composite slurry of molecular sieves.

[0037] (3) TiO 2 - Preparation of molecular sieve composite coating

[0038] Immerse the cordierite honeycomb carrier into the TiO prepared in step (3) 2 - ...

Embodiment 2

[0043] (1)Al 2 o 3 Sol preparation

[0044] Get 60 grams of pseudo-boehmite and add it to 200 g of deionized water, and add 16 g of concentrated nitric acid dropwise while stirring. After stirring for a certain period of time, heat to 60°C, add nitric acid dropwise until completely peptized, control the pH value of the solution at 5, and age for 24 hours to obtain a transparent aluminum sol.

[0045] (2) TiO 2 - Preparation of molecular sieve composite slurry

[0046] 56 g TiO 2 , 20 grams of molecular sieve and 8 grams of urea are mixed evenly, and 15 grams of Al 2 o 3 Sol, 200 grams of deionized water, and a concentration of 0.5mol L -1 Adjust the pH to 4, stir vigorously for 2 hours, and age at room temperature for 12 hours to obtain TiO 2 - Composite slurry of molecular sieves.

[0047] (3) TiO 2 - Preparation of molecular sieve composite coating

[0048] Immerse the cordierite honeycomb carrier into the TiO prepared in step (3) 2 - In the molecular sieve compo...

Embodiment 3

[0053] (1)Al 2 o 3 Sol preparation

[0054] Take 40 grams of pseudo-boehmite and add it to 200 grams of deionized water, and add 20 grams of concentrated nitric acid dropwise while stirring. After stirring for a certain period of time, heat to 80°C, add nitric acid dropwise until complete peptization, control the pH value of the solution at 4, and age for 24 hours to obtain a transparent aluminum sol.

[0055] (2) TiO 2 - Preparation of molecular sieve composite slurry

[0056] 35 g TiO 2 , 20 grams of molecular sieve and 4 grams of urea are mixed evenly, and 12 grams of Al 2 o 3 Sol, 200 grams of deionized water, and a concentration of 0.5mol L -1 Adjust the pH to 4 with nitric acid solution, stir vigorously for 2 hours, and age at room temperature for 12 hours to obtain TiO 2 - Composite slurry of molecular sieves.

[0057] (3) TiO 2 - Preparation of molecular sieve composite coating

[0058] will be coated with Al 2 o 3 The coated carrier is immersed in the TiO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com