A kind of preparation method of polyethylene glycol diazo polymer

A polyethylene glycol and polymer technology, applied in the field of ultraviolet photopolymerization, can solve the problems of poor coating stability and complex coating process, and achieve the effects of good repeatability, simple and fast preparation process, and simplified process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

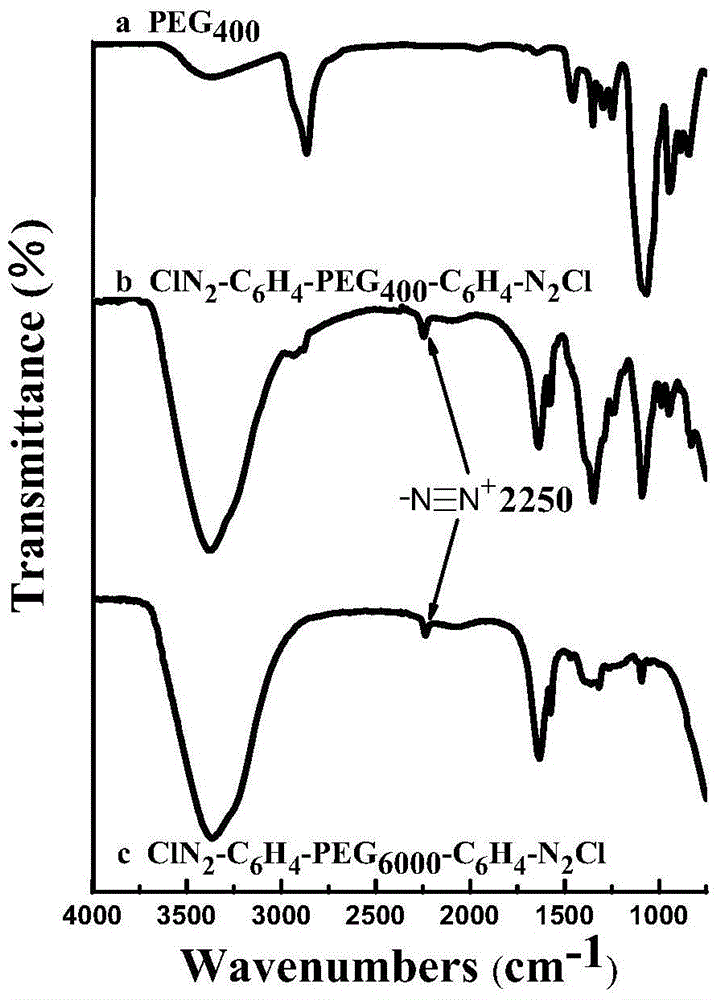

[0036] The preparation method of polyethylene glycol diazo polymer of the present invention comprises the following steps:

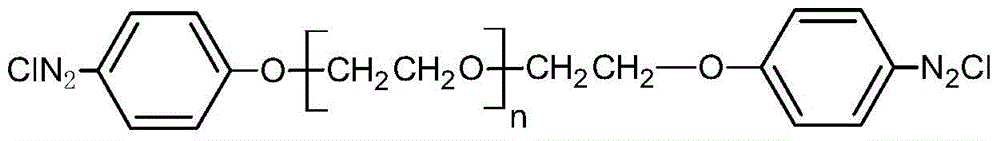

[0037] A kind of polyethylene glycol diazopolymer, it has structure shown in formula (1):

[0038]

[0039] Wherein n is an integer of 8-135.

[0040] Its synthesis process route is as follows:

[0041]

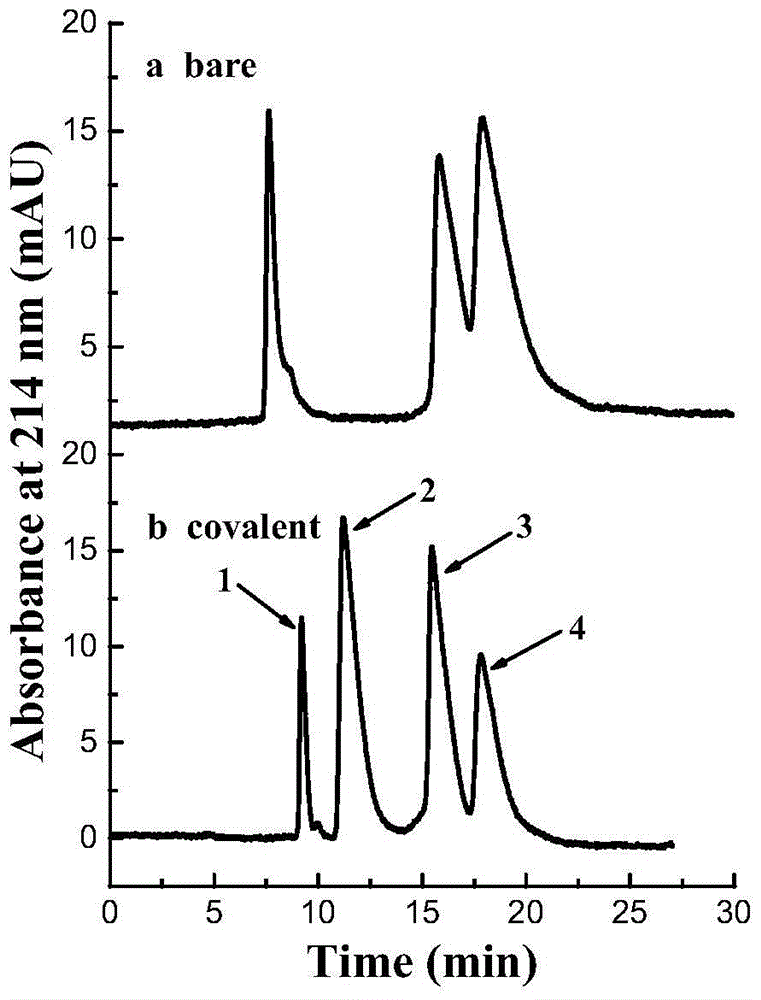

[0042] The method for activating the bare capillary column of the present invention comprises the steps:

[0043] successively use 0.1mol·L -1 Sodium hydroxide solution, distilled water, 0.1mol L -1 Salt

[0044] Rinse the bare capillary column with acid solution, distilled water and methanol for 30 min, 10 min, 30 min,

[0045] 10min and 10min, finally with N 2 Dry the bare capillary column to obtain an activated bare capillary column.

Embodiment 1

[0047] A preparation method of polyethylene glycol diazo polymer, comprising the steps of:

[0048] S1, synthesis of dichloropolyethylene glycol:

[0049] Put dried polyethylene glycol (PEG, molecular weight Mw of 400) and N,N-dimethylformamide (DMF) in a reaction kettle to form solution A; place thionyl chloride in a constant pressure dropping funnel middle,

[0050] To form solution B, add solution B drop by drop into solution A at 50°C until mixed evenly; the molar ratios of polyethylene glycol to N,N-dimethylformamide and thionyl chloride are respectively 1:2.0 and 1:3.0. After the mixed solution was reacted at 60°C under reflux for 20 hours, the product was washed with saturated brine, adjusted to pH 7.0 with anhydrous potassium carbonate, dried in vacuo to remove water, and filtered to remove sodium chloride to obtain the product dichloropolyethylene dichloride Alcohol (Cl-PEG-Cl);

[0051] S2, synthesis of amino-terminated phenyl polyethylene glycol:

[0052] P-ami...

Embodiment 2

[0060] A preparation method of polyethylene glycol diazo polymer, comprising the steps of:

[0061] S1, synthesis of dichloropolyethylene glycol:

[0062] Put dried polyethylene glycol (PEG, molecular weight Mw: 1000) and N,N-dimethylformamide (DMF) in a reaction kettle to form solution A; place thionyl chloride in a constant pressure dropping funnel , form B solution, and drop B solution into solution A drop by drop under the condition of 40°C until the mixture is uniform; the molar ratio of polyethylene glycol to N,N-dimethylformamide and thionyl chloride 1:1.5 and 1:2.0, respectively. After reacting the mixed solution at 85°C under reflux for 15 hours, the product was washed with saturated brine, adjusted to pH 7.0 with anhydrous potassium carbonate, dried in vacuo to remove water, and filtered to remove sodium chloride to obtain the product dichloropolyethylene dichloride Alcohol (Cl-PEG-Cl);

[0063] S2, synthesis of amino-terminated phenyl polyethylene glycol:

[006...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com