A kind of preparation method and application of polyvinyl alcohol diazo polymer

A technology of polyvinyl alcohol diazo and polyvinyl alcohol, which is applied in the field of polymerization, can solve problems such as poor coating stability and complicated coating process, and achieve the effects of good repeatability, simple and quick preparation process, and good hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

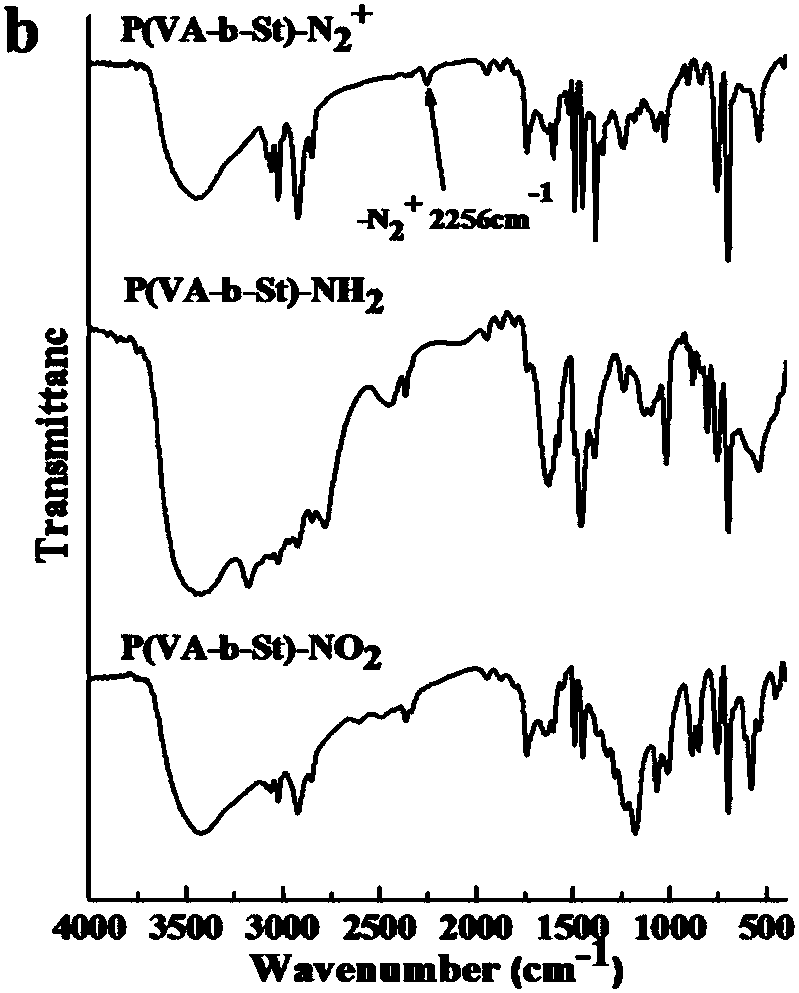

[0049] The preparation method of the polyvinyl alcohol diazo polymer of the present invention comprises the following steps:

[0050] A polyvinyl alcohol diazo polymer, it has the structure shown in formula (1):

[0051]

[0052] Where m is an integer of 5-10, and n is an integer of 8-15.

[0053] Its synthetic process route is as follows:

[0054]

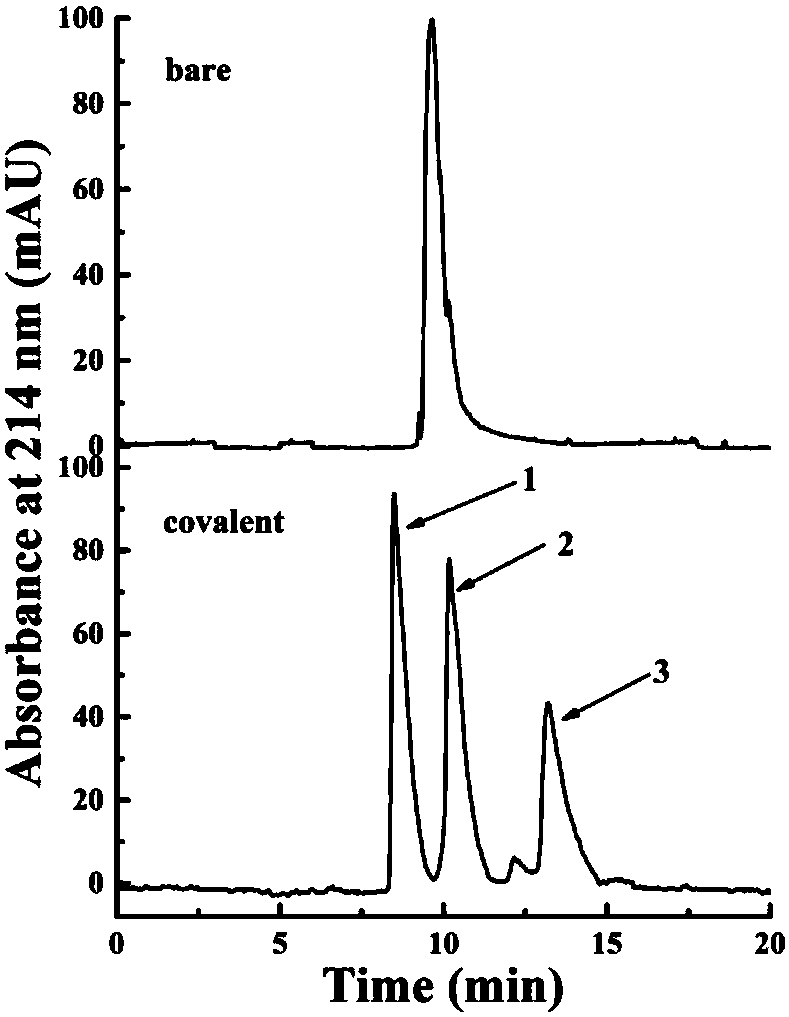

[0055] The method for activating a capillary bare column of the present invention comprises the following steps:

[0056] successively used 0.1mol·L -1 of sodium hydroxide solution, distilled water, 0.1mol·L -1 The bare capillary column was rinsed with hydrochloric acid solution, distilled water and methanol for 30min, 10min, 30min, 10min and 10min respectively, and finally with N 2 Blow dry the bare capillary column to obtain an activated bare capillary column.

Embodiment 1

[0058] A preparation method of polyvinyl alcohol diazo polymer, comprising the steps:

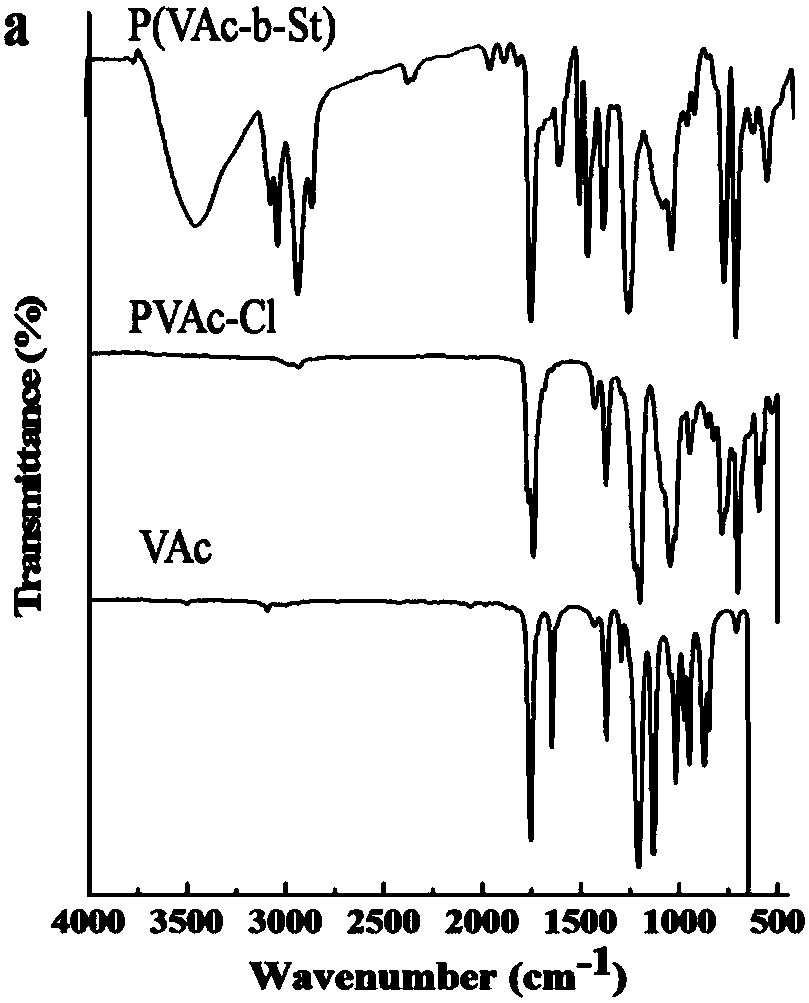

[0059] S1. Synthesis of chlorinated polyvinyl acetate (PVAc-Cl):

[0060] The dried vinyl acetate (VAc) was dissolved in acetone, and then the initiator azobisisobutyronitrile (AIBN) and the chain transfer agent carbon tetrachloride (CCl 4 ) was added to the round-bottomed flask; wherein the molar ratios of vinyl acetate to azobisisobutyronitrile and carbon tetrachloride were 1:0.001 and 1:0.03, respectively. After 3 times of nitrogen and vacuum pumping, the air was driven off to form an inert atmosphere, and the reaction was carried out at 60 °C for 6 h under reflux conditions. The product was then dissolved in methanol and precipitated with water. Repeated 3 times until a pale yellow solid was obtained, which was dried in vacuo. to constant weight to obtain the product chloropolyvinyl acetate;

[0061] S2. Synthesis of polyvinyl acetate-b-polystyrene (P(VAc-b-St)):

[0062] The catalys...

Embodiment 2

[0077] A preparation method of polyvinyl alcohol diazo polymer, comprising the steps:

[0078] S1. Synthesis of chlorinated polyvinyl acetate:

[0079] The dried vinyl acetate (VAc) was dissolved in N,N-dimethylformamide, and then the initiator azobisisobutyronitrile (AIBN) and the chain transfer agent carbon tetrachloride (CCl 4 ) was added to the round-bottomed flask; wherein the molar ratios of vinyl acetate to azobisisobutyronitrile and carbon tetrachloride were 1:0.002 and 1:0.04, respectively. After 3 times of nitrogen and vacuum pumping to drive out the air to form an inert atmosphere, the reaction was carried out at 50 °C for 5 hours under reflux conditions, and then the product was dissolved in methanol and precipitated with water, repeated twice until a pale yellow solid was obtained, which was dried in vacuo to constant weight to obtain the product macroinitiator chloropolyvinyl acetate;

[0080] S2. Synthesis of polyvinyl acetate-b-polystyrene (P(VAc-b-St)):

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com