A preparation method of anti-protein adsorption capillary electrophoresis covalently bonded coating column

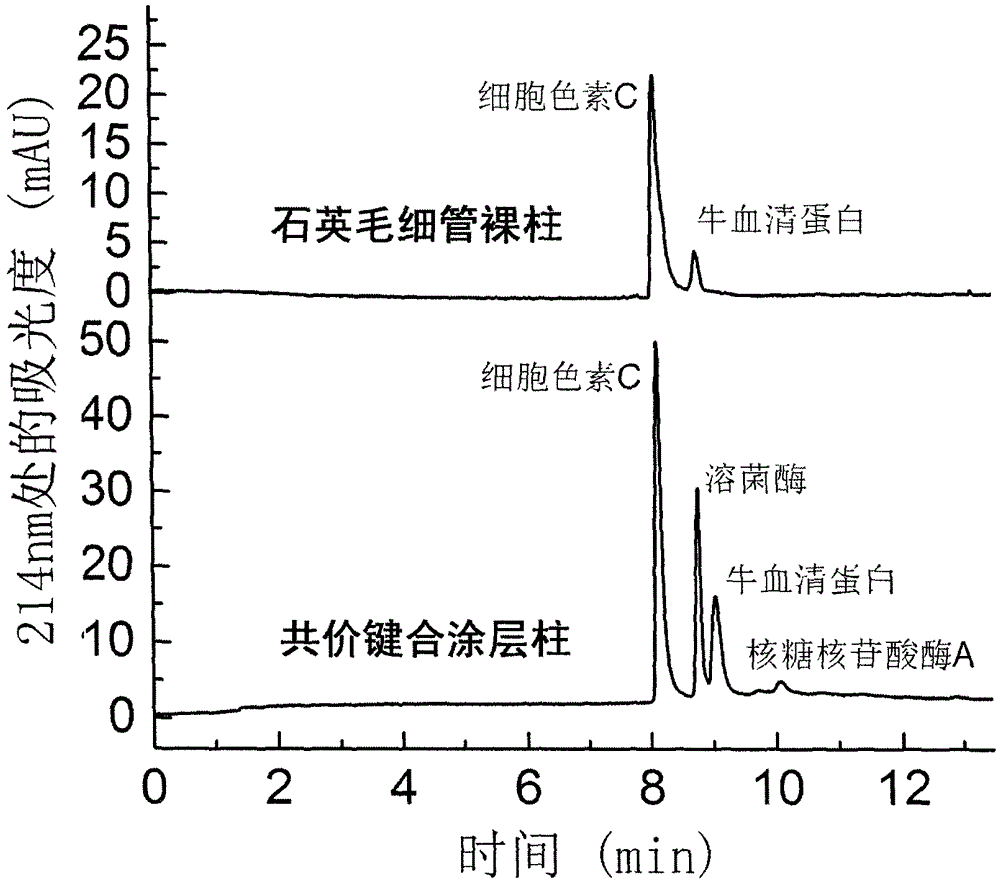

A technology of capillary electrophoresis and anti-protein adsorption, which is applied in separation methods, chemical instruments and methods, and material analysis by electromagnetic means, and can solve the problem of poor quality of anti-protein adsorption capillary electrophoresis covalently bonded coating columns and preparation process Problems such as complex process and high toxicity in the production process, to achieve the effect of green production process, simple process equipment, and overcome coating quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] At 1°C, wash a new bare quartz capillary column with an aqueous solution of diazo resin (molecular weight: 400) at a concentration of 0.01 mg / ml for 5 minutes, and then rinse it with distilled water for 1 minute. Then rinse with 0.01 mg / ml sodium polystyrene sulfonate (molecular weight: 5000) aqueous solution for 5 minutes, and then rinse with distilled water for 1 minute, thus completing one cycle of electrostatic self-assembly. After assembling one cycle, the capillary was blown dry with compressed air, and exposed under a UV lamp with a wavelength of 193nm, and the exposure dose was 5mJ / cm 2 , to form an anti-protein adsorption covalently bonded coating column with a diazo resin-sodium polystyrene sulfonate 2-layer composite structure. Since the covalent cross-linking reaction between the silanol on the inner wall of the quartz capillary and the coating is shielded, the covalently bonded coating column has good anti-protein adsorption performance.

Embodiment 2

[0023] At 50°C, a new bare quartz capillary column was first rinsed with an aqueous solution of diazo resin (molecular weight: 100,000) at a concentration of 1000 mg / ml for 5 minutes, and then rinsed with distilled water for 1 minute. Then rinse with an aqueous solution of sodium polystyrene sulfonate (molecular weight: 600,000) at a concentration of 1000 mg / ml for 5 minutes, and then rinse with distilled water for 1 minute, thus completing an electrostatic self-assembly cycle. After repeated assembly for 6 cycles, the capillary was blown dry with compressed air, and exposed to a UV lamp with a wavelength of 400nm, and the exposure dose was 20000mJ / cm 2 , to form an anti-protein adsorption covalently bonded coating column with a diazo resin-sodium polystyrene sulfonate 12-layer composite structure. Since the covalent cross-linking reaction between the silanol on the inner wall of the quartz capillary and the coating is shielded, the covalently bonded coating column has good an...

Embodiment 3

[0025] At 20°C, a new bare quartz capillary column was first rinsed with an aqueous solution of diazo resin (molecular weight 750) at a concentration of 0.1 mg / ml for 5 minutes, and then rinsed with distilled water for 1 minute. Then rinse with 0.1 mg / ml sodium polystyrene sulfonate (molecular weight: 10,000) aqueous solution for 5 minutes, and then rinse with distilled water for 1 minute, thus completing one cycle of electrostatic self-assembly. After repeated assembly for 5 cycles, the capillary was blown dry with compressed air and exposed to a UV lamp with a wavelength of 248nm at a dose of 30mJ / cm 2 , the anti-protein adsorption covalent bonding coating column with diazo resin-sodium polystyrene sulfonate 10-layer composite structure can be formed. Since the covalent cross-linking reaction between the silanol on the inner wall of the quartz capillary and the coating is shielded, the covalently bonded coating column has good anti-protein adsorption performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com