A kind of method of coal tar fixed bed hydrotreating co-production refining soft pitch

A hydrorefining reaction and coal tar technology, which is applied in tar processing, tar processing by distillation, tar pitch/petroleum pitch/natural pitch by distillation, etc., can solve the problems of high investment, energy consumption and cost, and achieve Good solubility, low process energy consumption, high content of aromatics and saturated hydrocarbons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

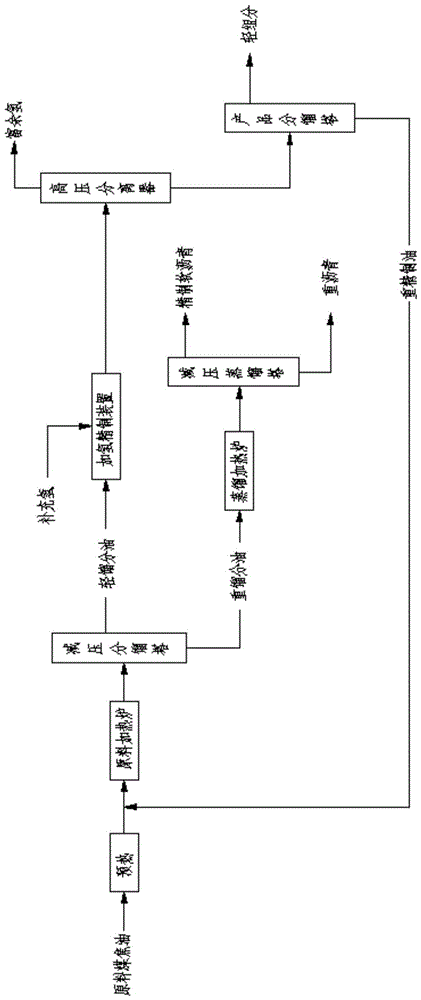

Image

Examples

Embodiment 1

[0036] A method for coal tar fixed-bed hydrogenation co-production of refined soft pitch, the processing steps are as follows:

[0037] (a) Low-temperature coal tar in the raw material (properties are shown in Table 1) is mixed with the heavy refined oil returned in the subsequent steps after preheating, enters the raw material heating furnace for heating, and then enters the vacuum fractionation tower for vacuum fractionation to obtain light distillate oil and For heavy distillates, the cut point of vacuum fractionation is 420°C;

[0038] (b) The light distillate oil obtained in step (a) enters the fixed-bed hydrofinishing unit, contacts with the hydrofinishing catalyst in the presence of hydrogen, and carries out the hydrofinishing reaction. The hydrofinishing reaction conditions are: reaction temperature 270° C., pressure 12.0MPa, hydrogen oil volume ratio 1200:1, volume space velocity 1hr - ;

[0039] (c) The hydrorefining reaction product obtained in step (b) is separat...

Embodiment 2

[0044] A method for coal tar fixed-bed hydrogenation co-production of refined soft pitch, the processing steps are as follows:

[0045] (a) Raw material high-temperature coal tar (see Table 2 for properties) is mixed with the heavy refined oil returned in the subsequent steps after preheating, enters the raw material heating furnace for heating, and then enters the vacuum fractionation tower for vacuum fractionation to obtain light distillate oil and heavy oil For distillate oil, the cut point of vacuum fractionation is 400°C;

[0046] (b) The light distillate oil obtained in step (a) enters the fixed-bed hydrofinishing unit, contacts with the hydrofinishing catalyst in the presence of hydrogen, and carries out the hydrofinishing reaction. The hydrofinishing reaction conditions are: reaction temperature 290° C., pressure 13.0MPa, hydrogen oil volume ratio 1200:1, volume space velocity 0.8hr - ;

[0047] (c) The hydrorefining reaction product obtained in step (b) is separated...

Embodiment 4

[0050] The indicators of the refined soft asphalt obtained in Example 4 are shown in Table 6.

[0051] Table 1: Properties of medium and low temperature coal tar as raw material

[0052] project data Density(20℃),g / cm 3

[0053] Viscosity(100℃),mm 2 / s -1

[0054] Table 2: Raw material high temperature coal tar properties table

[0055] project data Density(20℃),g / cm 3

[0056] 90% 542 EBP / Viscosity(100℃),mm 2 / s -1

[0057] Table 3: Properties of Heavy Refined Oil in Example 1

[0058] project data Density(20℃),g / cm 3

[0059] Ni,μg / g <0.1

[0060] Table 4: Example 2 Heavy Refined Oil Property Table

[0061] project data Density(20℃),g / cm 3

[0062] Table 5: Table of properties of refined soft asphalt in Example 1

[0063] project data Density(20℃),g / cm 3

[0064] Ash, wt% 0.003 S,wt% <0.02

[0065] Table 6: Tabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com