Surface-modified anode material for lithium ion battery and preparation method thereof

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problem of material discharge specific capacity or energy density reduction, metal oxides do not have electrochemical activity, and material cycle performance does not improve, etc. problems, to achieve the effect of sufficient raw material resources, good industrial application prospects, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] La 2 o 3 and BaTiO 3 Press Ba 0.998 La 0.002 TiO 3 The stoichiometric ratio ingredients are wet-mixed, mixed uniformly, dried, and lanthanum-doped modified barium titanate powder is obtained after sintering and grinding. Add the lanthanum-doped modified barium titanate powder into absolute ethanol for high-speed stirring for 30 minutes, then perform ultrasonication for 10 minutes, successively high-speed stirring and ultrasonic circulation for 3 to 5 times, and mix uniformly to form a uniform solution. The active material LiNi 0.8 co 0.15 Al 0.05 o 2 Add it into the above mixed solution under the condition of high-speed stirring, so that the coating material is uniformly coated on the active material LiNi 0.8 co 0.15 Al 0.05 o 2 surface, and then the mixture was dried for 6 hours, and the dried solid material was calcined at 500° C. for 10 hours, then cooled, pulverized, and sieved to obtain the positive electrode material.

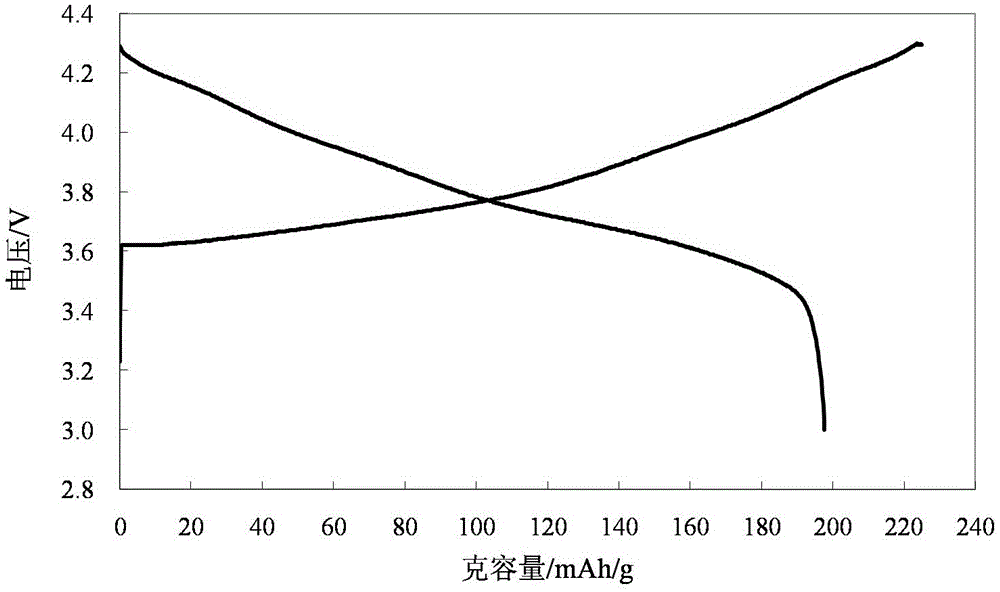

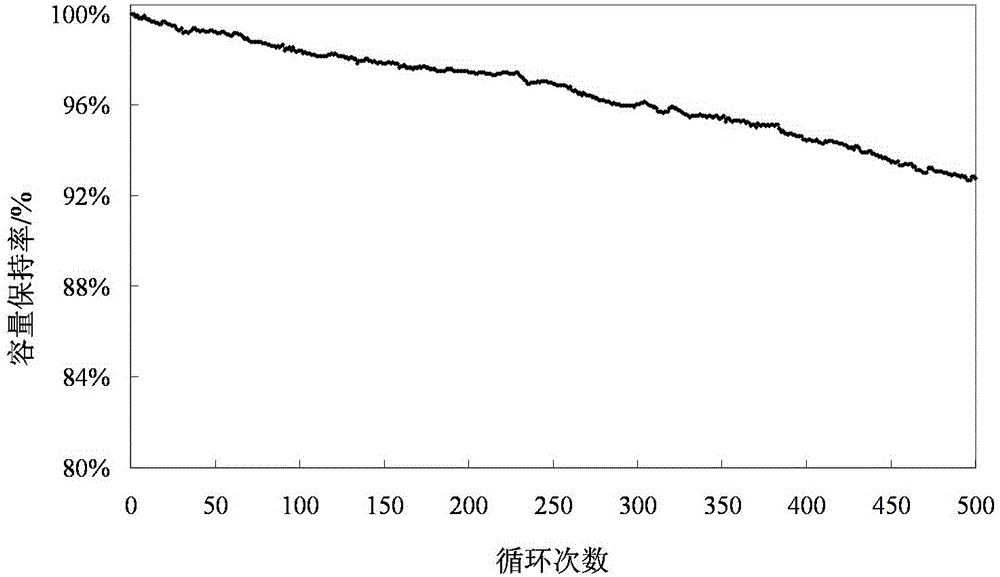

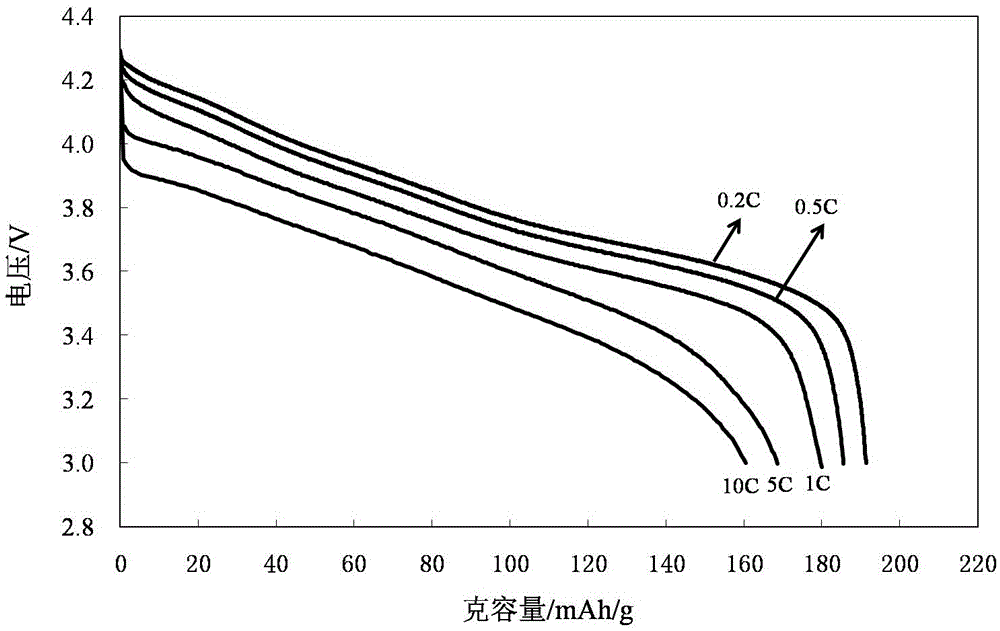

[0028] The electrochemical perf...

Embodiment 2

[0030] Will Nb 2 o 5 and BaTiO 3 Press BaTi 0.997 Nb 0.003 o 3 The stoichiometric ratio ingredients are wet-mixed, mixed uniformly, dried, sintered and ground to obtain niobium-doped modified barium titanate powder. Add the niobium-doped modified barium titanate powder into deionized water for 30 minutes of high-speed stirring, and then perform ultrasonication for 10 minutes, followed by high-speed stirring and ultrasonic circulation for 3 to 5 times, and mix uniformly to form a uniform solution. The active material LiNi 0.75 co 0.2 Al 0.05 o 2 Add it into the above mixed solution under the condition of high-speed stirring, so that the coating material is uniformly coated on the active material LiNi 0.75 co 0.2 Al 0.05 o 2 Then, the mixture was dried for 8 hours, and the dried solid material was calcined at 600° C. for 8 hours, then cooled, pulverized, and sieved to obtain the positive electrode material.

Embodiment 3

[0032] Will Y 2 o 3 and BaTiO 3 Press Ba 0.999 Y 0.001 TiO 3 The stoichiometric ratio ingredients are wet-mixed, mixed uniformly, dried, sintered and ground to obtain yttrium-doped modified barium titanate powder. Add the yttrium-doped modified barium titanate powder into absolute ethanol for 30 minutes of high-speed stirring, and then perform ultrasonication for 10 minutes, followed by high-speed stirring and ultrasonic circulation for 3 to 5 times, and mix uniformly to form a uniform solution. The active material LiNi 0.7 co 0.2 Al 0.1 o 2 Add it into the above mixed solution under the condition of high-speed stirring, so that the coating material is uniformly coated on the active material LiNi 0.7 co 0.2 Al 0.1 o 2 surface, and then the mixture was dried for 7 hours, and the dried solid material was calcined at 800° C. for 6 hours, cooled, pulverized, and sieved to obtain the positive electrode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com