High-flux high-interception-rate positive charge composite nanofiltration membrane and preparing method of high-flux high-interception-rate positive charge composite nanofiltration membrane

A composite nanofiltration membrane and positive charge technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems affecting the promotion of positive charge membranes, easy loss of polyethyleneimine, and easy loss of charged materials, etc. problem, to achieve the effect of improving water flux, strong hydrophilicity and short production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for preparing a positively charged composite nanofiltration membrane with high throughput and high rejection rate, comprising the steps of:

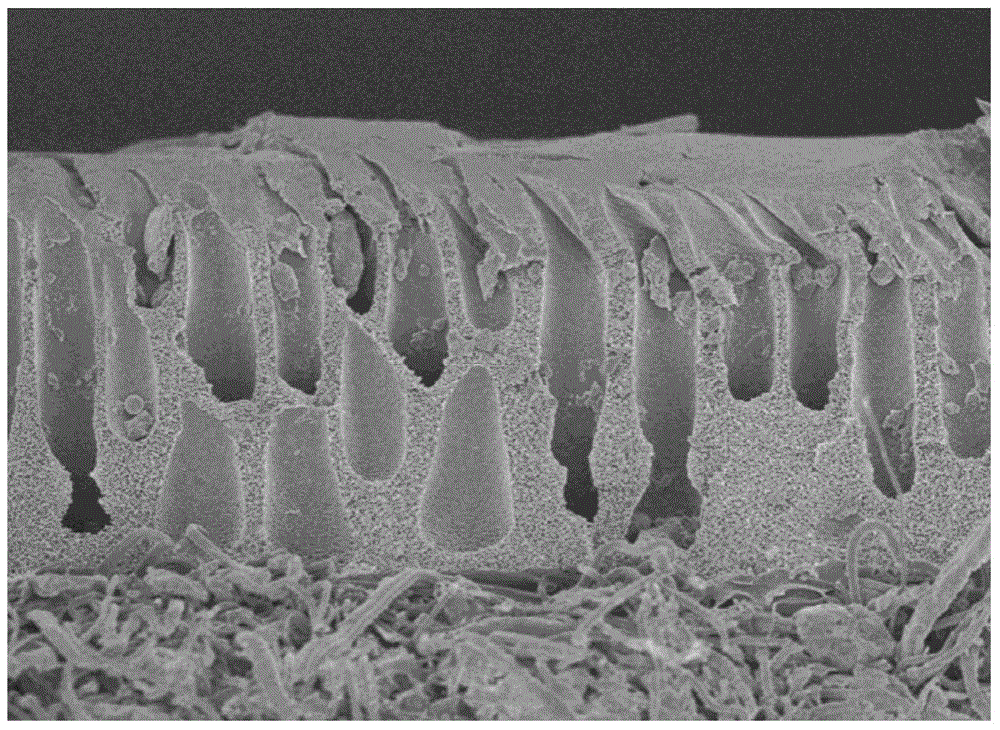

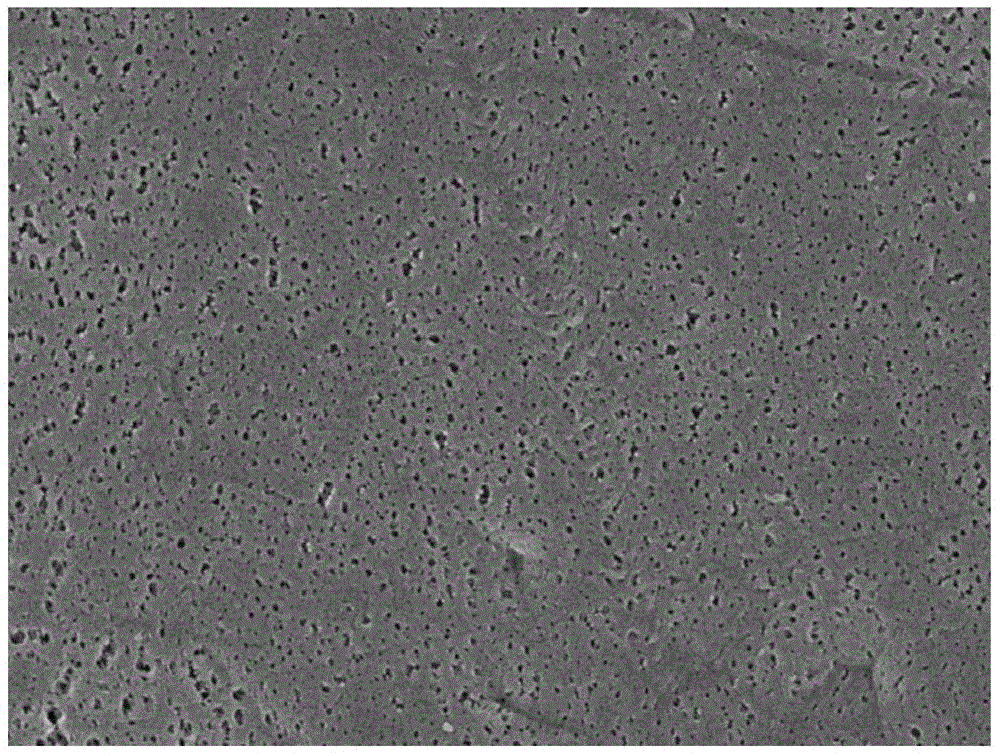

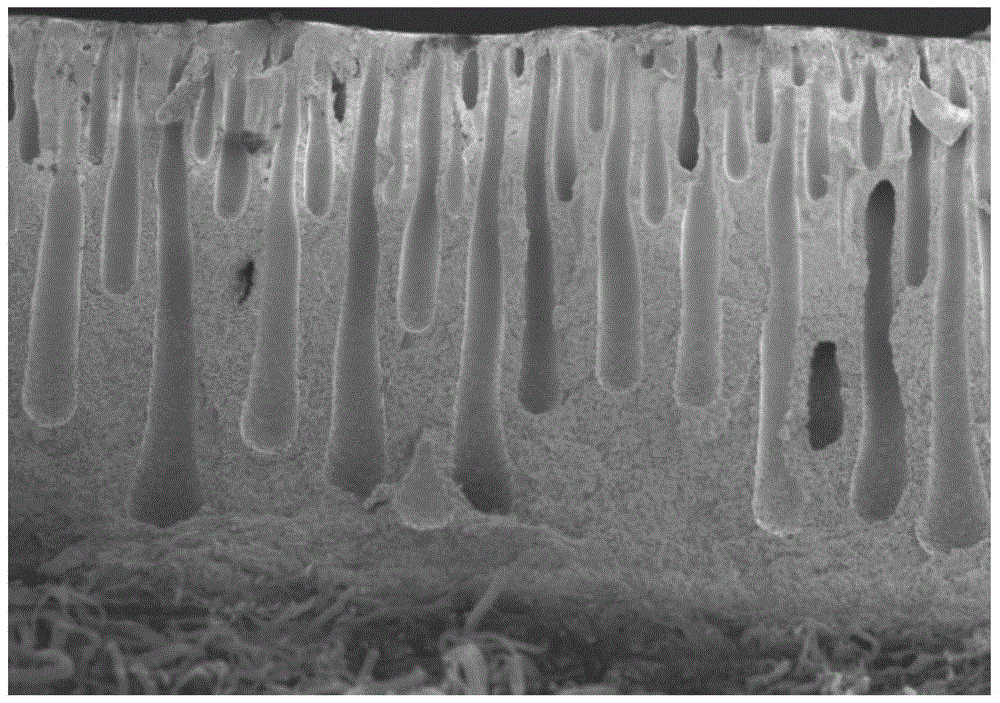

[0035] (1) Dissolve polyetherimide in N,N-dimethylacetamide to form a polyetherimide solution with a mass concentration of 15%, stir for 3 hours at 80°C, and let stand for defoaming for 24 Hours, made casting solution, proportionally at 600cm 2 Scrape 15g of casting solution on the smooth surface of non-woven fabric made of polypropylene, put it into ethylenediamine aqueous solution with a mass concentration of 3%, soak for 5min, take it out and rinse it with deionized water, and get the cross-linked solution after drying. The associated basement membrane (see figure 1 , 2 ), the side of the scraped casting solution of the non-woven fabric is called the A side;

[0036] (2) m-phenylenediamine and positive charge material are put into water and made into aqueous solution, make the mass concentration of m-phenylene diami...

Embodiment 2

[0040] A method for preparing a positively charged composite nanofiltration membrane with high throughput and high rejection rate, comprising the steps of:

[0041] (1) Dissolve polyetherimide in an organic solvent to prepare a polyetherimide solution with a mass concentration of 20%, stir for 8 hours at 40°C, and stand for defoaming for 3 hours to make a casting solution , proportionally at 600cm2 Scrape 20g of the casting solution on the smooth surface of the non-woven fabric made of polyacrylonitrile, place it in the air for 60 seconds, put it into an aqueous solution of ethylenediamine with a mass concentration of 12%, and soak it for 60 minutes. Take out and rinse with deionized water, dry to obtain a cross-linked base film, and call the side of the non-woven fabric scraping and casting film liquid A side;

[0042] The organic solvent is N,N-dimethylformamide and 1,4-dioxane with a volume ratio of 1:1;

[0043] (2) m-phenylenediamine and positive charge material are put ...

Embodiment 3

[0047] A method for preparing a positively charged composite nanofiltration membrane with high throughput and high rejection rate, comprising the steps of:

[0048] (1) Dissolve polyetherimide in N,N-dimethylacetamide to form a polyetherimide solution with a mass concentration of 30%, stir for 6 hours at 60°C, and let stand for defoaming for 12 Hours, made casting solution, proportionally at 600cm 2 Scrape 16g of casting solution on the smooth surface of non-woven fabric made of polyester, place it in the air for 3 seconds, put it into an aqueous solution of ethylenediamine with a mass concentration of 5%, soak it for 30 minutes, take it out Rinse with deionized water, dry to obtain a cross-linked base film, and call the side of the non-woven fabric scraping and casting film liquid A side;

[0049] (2) m-phenylenediamine and positively charged material are put into water and made into aqueous solution, make the mass concentration of m-phenylenediamine be 2%, make the mass con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com