Method for preparing TiFe alloy by reducing ferrotitanium oxide under microwave field

An iron oxide and oxide technology, applied in the field of TiFe alloy, can solve the problems of poor thermal conductivity of metal oxide powder, low energy utilization rate, high raw material cost, avoid poor thermal conductivity, improve preparation process and performance, and improve The effect of activation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

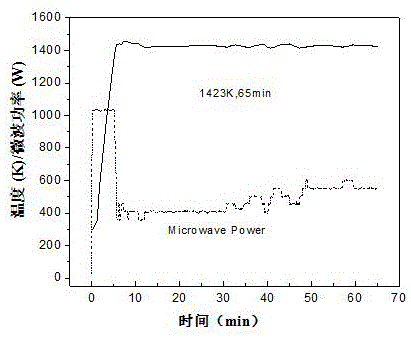

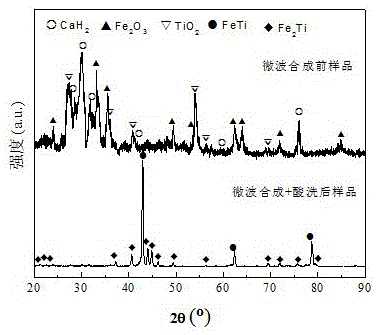

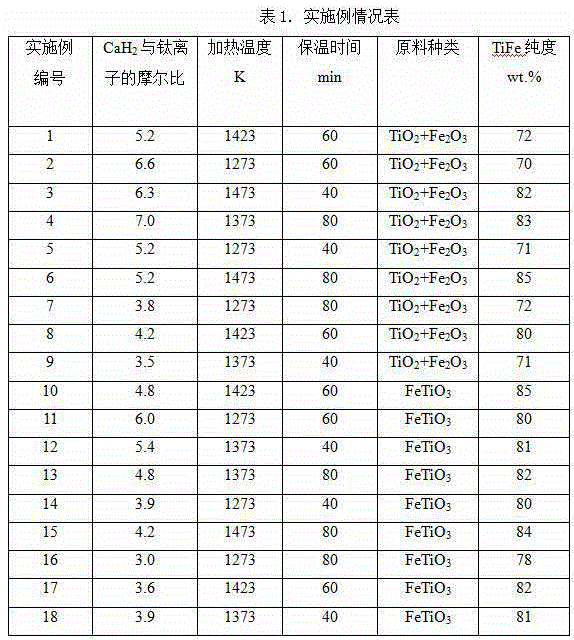

[0027] According to titanium ion, iron ion and CaH 2 The molar ratio is: 1.0:1.0:5.2 ratio to weigh TiO 2 (purity 99.8%), Fe 2 o 3 (purity 99%) and CaH 2 (98.5% purity) powder, put the above raw materials together in a ball mill and mix them thoroughly. The ball-to-material weight ratio in the ball mill is 10:1, that is, every 1 g of powder requires 10 g of balls, the main shaft speed of the ball mill is 300 rpm, and the counter shaft speed is -450 rpm ("- "Represents the opposite direction), the ball milling time is 4 hours, milling for 30 minutes and stopping for 30 minutes; in order to prevent powder oxidation, sample weighing, ball milling tank sample filling and sampling are all carried out in a glove box under the protection of Ar atmosphere. Put the above ball-milled uniform sample in a microwave tube furnace, evacuate and pass high-purity argon (≥99.999%) protection, turn on the microwave power supply, use 1000W microwave radiation to heat the sample to 1423K withi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com